DC Inverter Cassette Type Air Conditioner Installation and Operation Manual

44

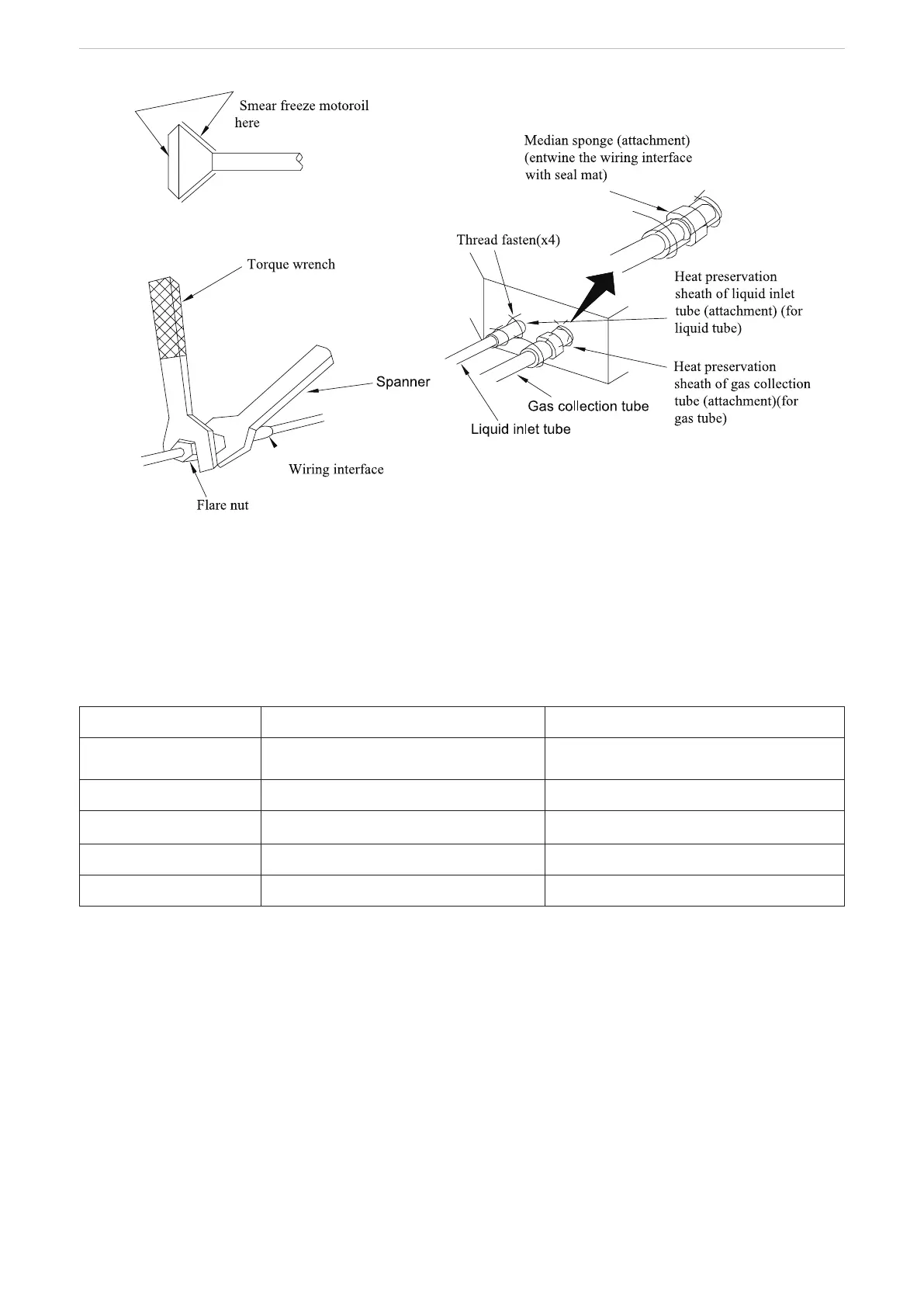

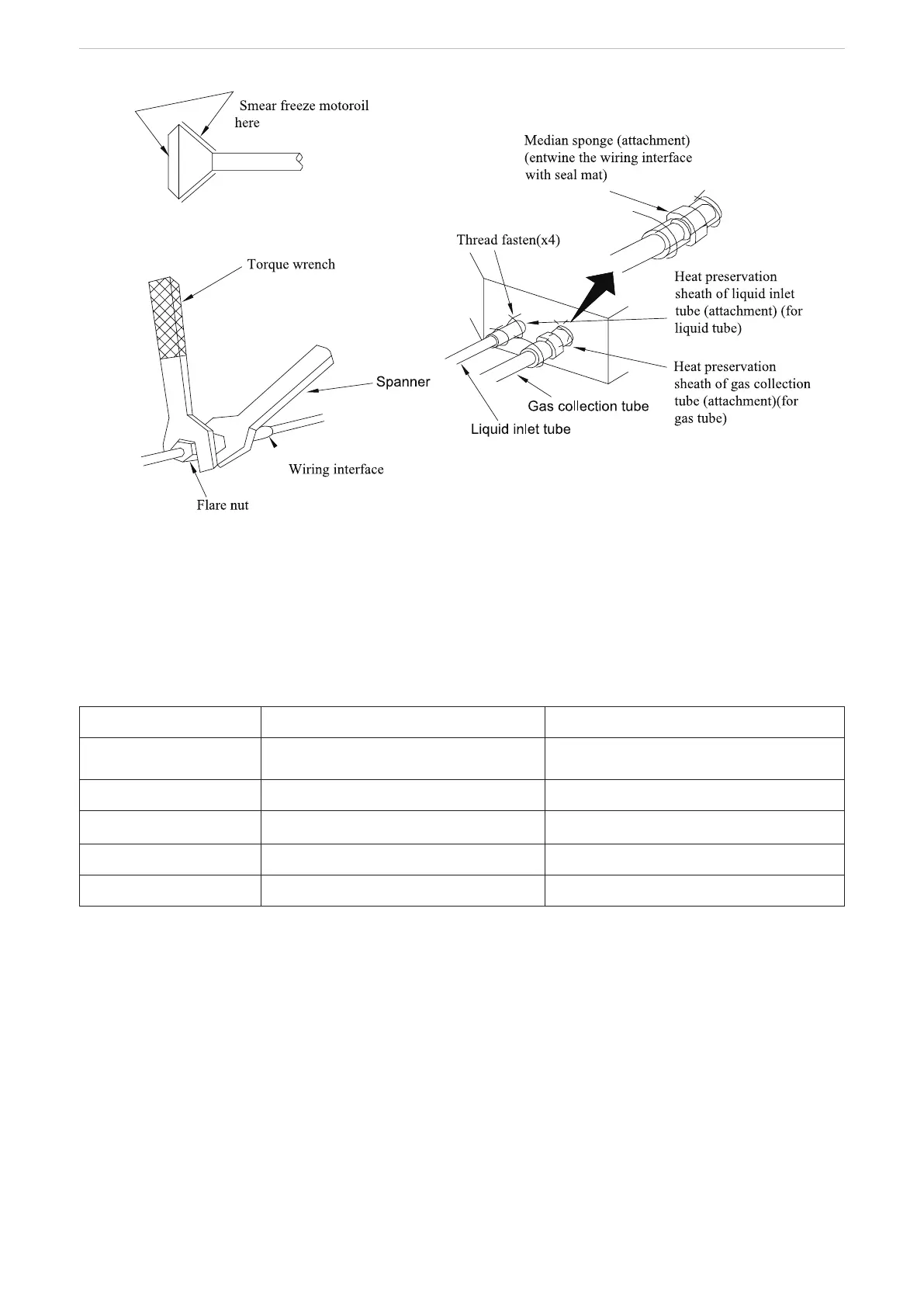

Fig.22

● When connect the pipe to the unit or backout it from the unit, please do use both spanner and torque

wrench. As shown in Fig.22.

● When connect, smear both inside and outside of the are nut with freeze motor oil, screw it by hand and

then tighten it with spanner.

● Refer to Table 4 to check if the wrench had been tightened (too tight would mangle the nut and lead

leakage).

Table 4 the tightening torque needed for tightening nut

Diameter(Inch) Surface thickness(mm) Tightening torque (N·m)

φ1/4 ≥0.5 15-30

φ3/8 ≥0.71 30-40

φ1/2 ≥1 45-50

φ5/8 ≥1 60-65

φ3/4 ≥1 70-75

● Examine the connection pipe to see if it had gas leakage, and then take the treatment of heat insulation, as

shown in the Fig.22.

● Only use median sponge to entwine the wiring interface of the gas pipe and heat preservation sheath of

the gas collection tube.

8.2.7 Drainage hose

1.Install the drain hose

● The diameter of the drain hose should be equal or bigger than the connection pipe’s. (The diameter of

polythene pipe: Outer diameter 25mm Surface thickness ≥1.5mm)

● Drain hose should be short and drooping gradient should at less 1/100 to prevent the formation of air

bubble.

● If drain hose cannot has enough drooping gradient, drain raising pipe should be added.

● To prevent bent of the drain hose, the distance between hoisting stand should is 1 to 1.5m.

Loading...

Loading...