^PffONlNG

THE

LOOPER

AN

EQUAL

DISTANCE

(FRONT

AND

REAR)

FROMNEEDLE

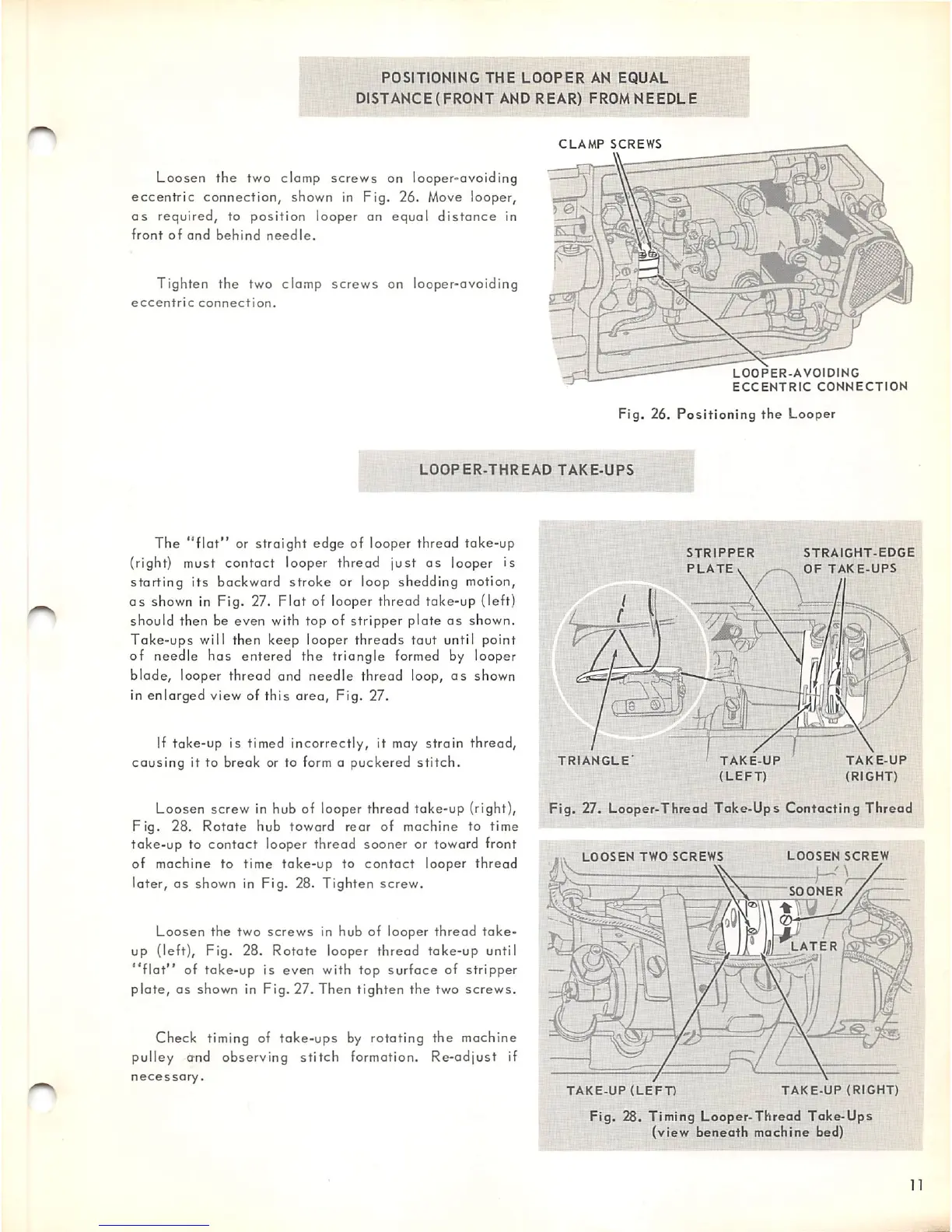

Loosen

the

two clamp

screws

on looper-avoiding

eccentric

connection, shown in Fig. 26. Move looper,

as

required, to

position

looper an

equal

distance

in

front

of

and

behind

needle.

Tighten

the

two clamp

screws

on looper-ovoiding

eccentric

connection.

CLAMP

SCREWS

)

©K

LOOPER.AVOIDING

ECCENTRIC

CONNECTION

Fig.

26.

Positioning

the

Looper

LODPER-THREAD

TAKE-UPS

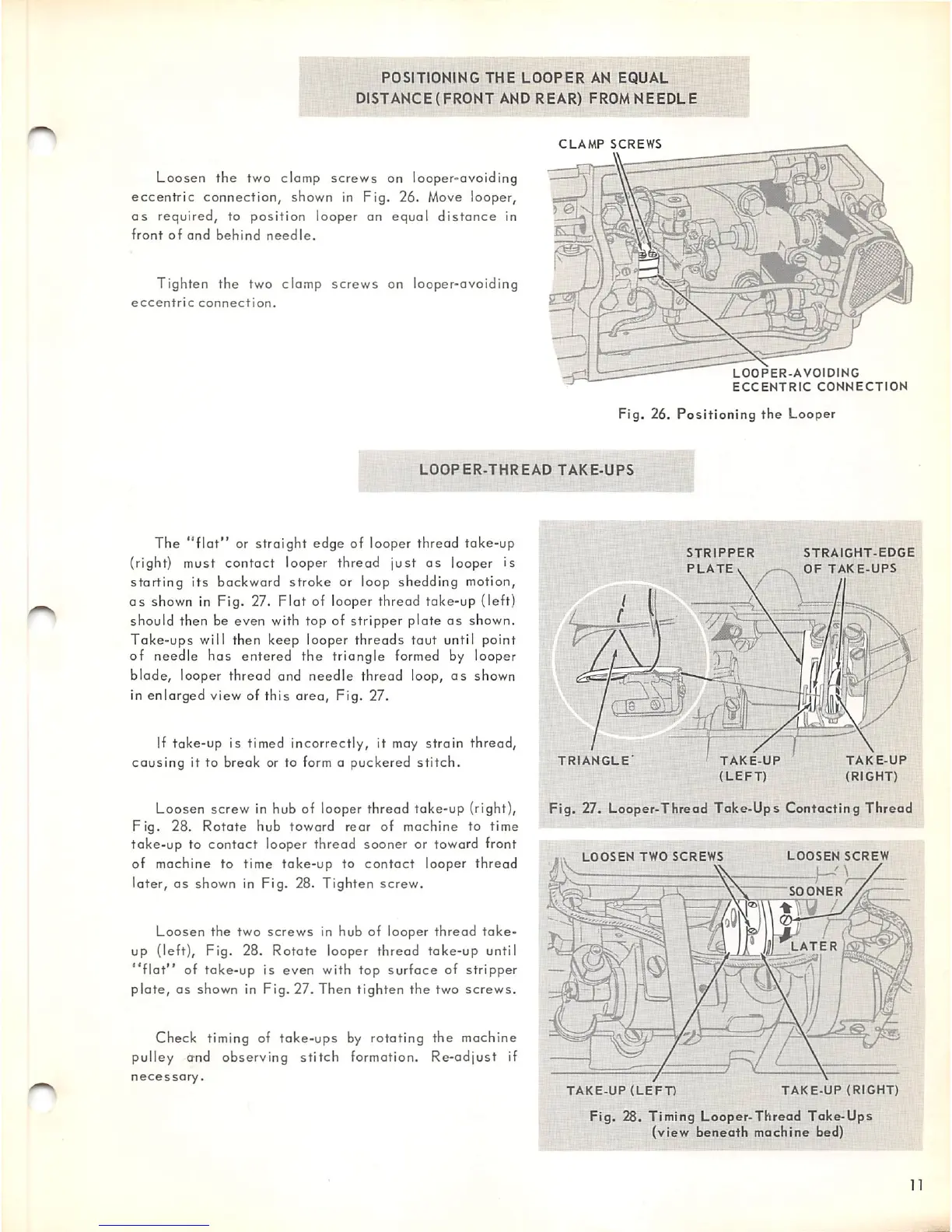

The

"flat"

or

straight

edge of looper thread take-up

(right) must

contact

looper thread

just

as

looper is

starting

its

backward

stroke

or loop shedding motion,

as

shown in Fig. 27.

Flat

of looper thread take-up (left)

should then be

even

with top of

stripper

plate

as

shown.

Take-ups

will then keep looper

threads

taut

until point

of

needle

has

entered

the

triangle

formed by looper

blade, looper thread and

needle

thread loop,

as

shown

in enlarged view of this area. Fig. 27.

If take-up is timed incorrectly, it may strain thread,

causing

it to

break

or to form a

puckered

stitch.

Loosen screw in hub of looper thread take-up (right),

Fig.

28.

Rotate

hub toward rear of machine to time

take-up

to

contact

looper thread sooner or toward front

of machine to time take-up to

contact

looper

thread

later,

as shown in Fig. 28. Tighten screw.

Loosen

the

two

screws

in hub of looper

thread

take-

up (left), Fig. 28.

Rotate

looper thread take-up until

"flat"

of take-up Is even with top

surface

of stripper

plate,

as shown in

Fig.

27. Then

tighten

the

two

screws.

Check timing of take-ups by rotating the machine

pulley and observing

stitch

formation. Re-odjust if

necessary.

TRIANGLE

STRIPPER

STRAIGHT-EDGE

PLATE

V

OF

TAKE-UPS

TAKE-UP

(LEFT)

TAKE-UP

(RIGHT)

Fig. 27. Looper-Threod

Take-Ups

Contacting

Thread

LOOSEN

TWO

SCREWS

TAKE-UP

(LEFT)

LOOSEN

SCREW

SOONER

/

LATER

tX)

TAKE-UP

(RIGHT)

Fig.

28. Timing

Looper-Thread

Take-Ups

(view

beneath

machine

bed)

11

Loading...

Loading...