NEEDLE

BAR

HEIGHT

Set looper at gauge distance

from

needle and time

looper, as instructed on page 9.

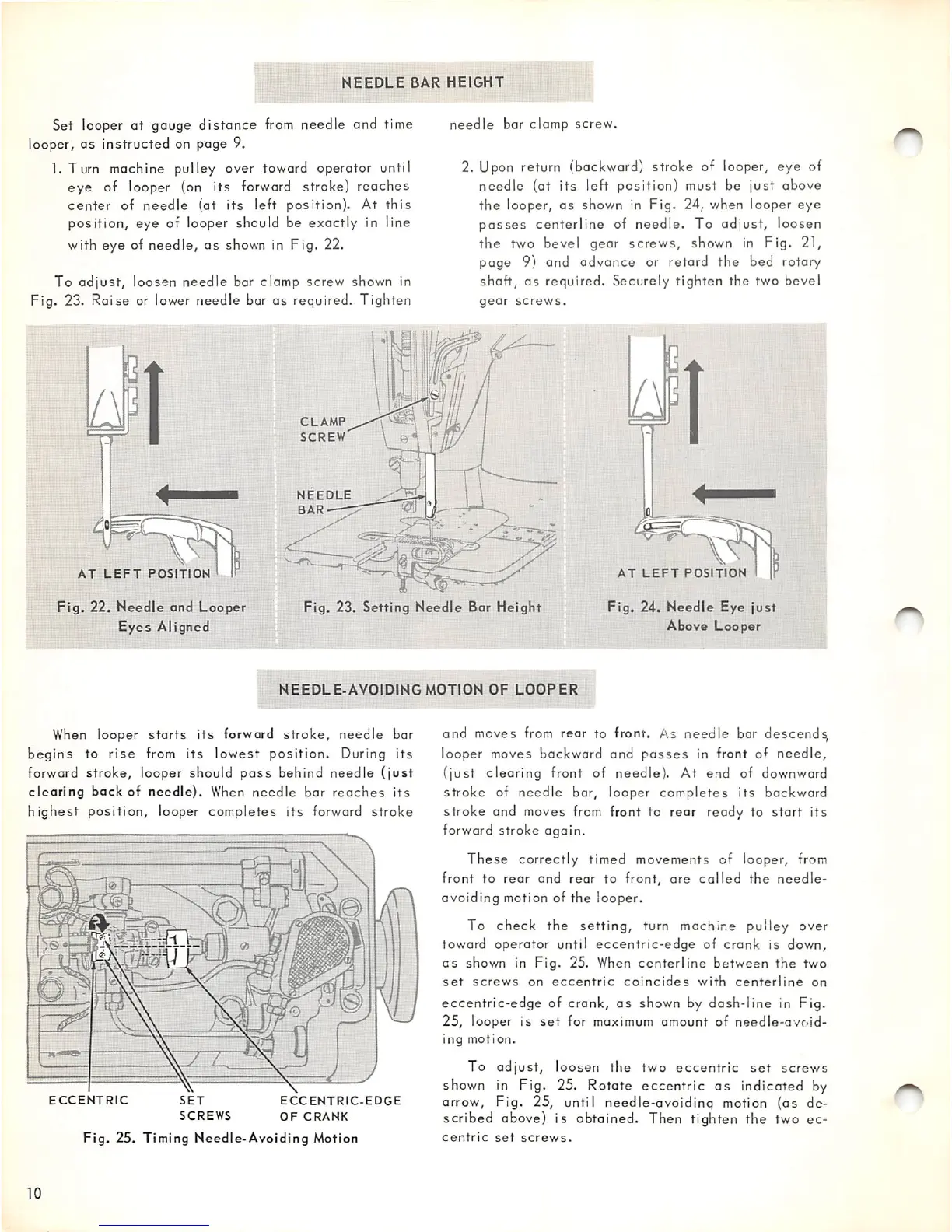

l.Turn

machine pulley over toward operator until

eye of looper (on its

forward

stroke) reaches

center

of

needle

(at

its

left position). At

this

position, eye of looper should be exactly in line

with

eye

of

needle,

as

shown in

Fig.

22.

To

adjust,

loosen

needle

bar clamp

screw

shown in

Fig. 23. Raise or lower needle bar as required. Tighten

AT

LEFT

POSITION

CLAMP

SCREW

needle

bar clamp

screw.

2. Upon return (backward) stroke of looper, eye of

needle

(at

its

left position) must be

just

above

the

looper,

as

shown in Fig. 24, when looper

eye

passes

centerline of needle. To adjust, loosen

the

two bevel gear screws, shown in Fig. 21,

page

9) and

advance

or retard

the

bed rotary

shaft,

as

required. Securely tighten the two bevel

gear

screws.

AT

LEFT

POSITION

Fig.

22.

Needle

and

Looper

Eyes

Aligned

Fig.

23.

Setting

Needle

Bar

Height

Fig.

24.

Needle

Eye

just

Above

Looper

NEEDLE-AVOIDING

MOTION

OF

LOOPER

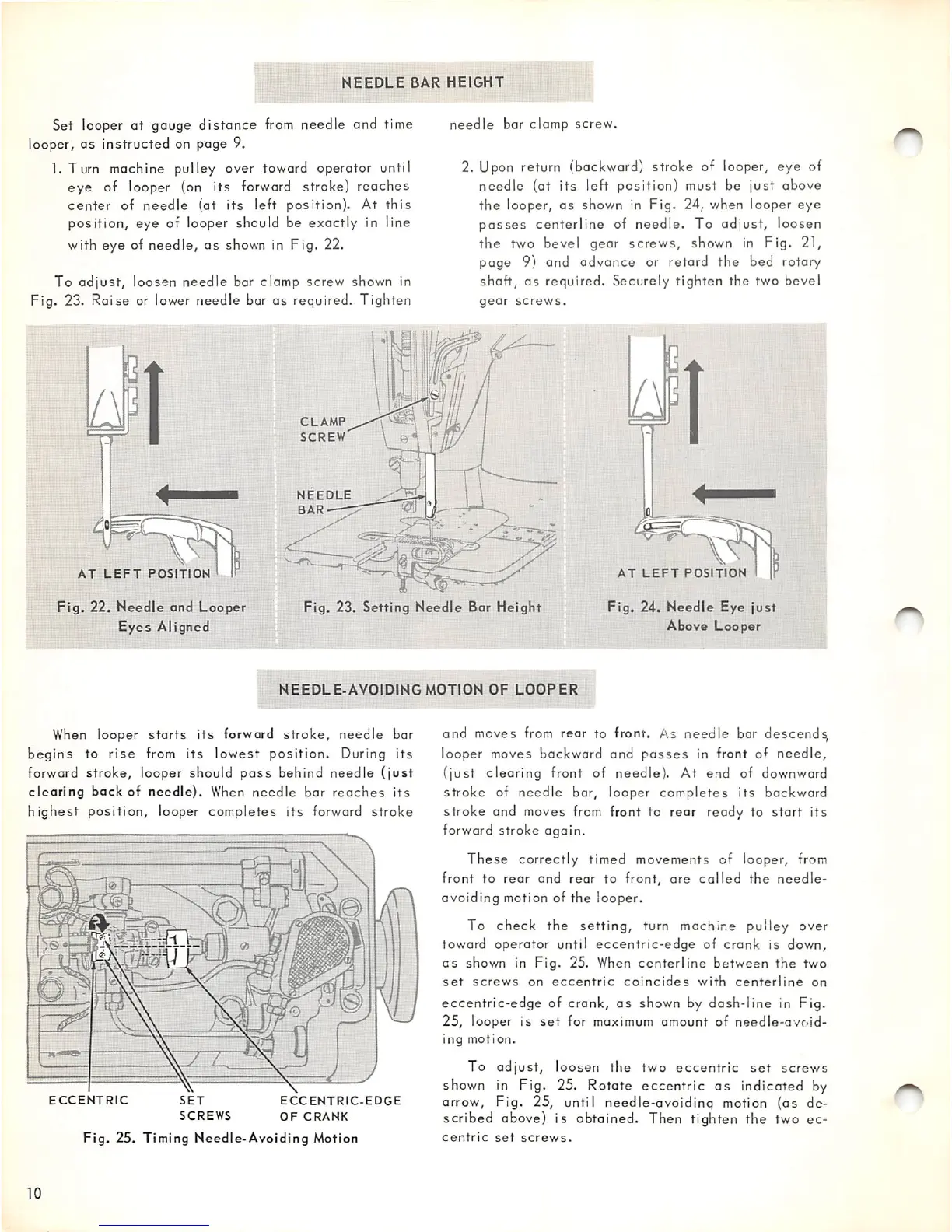

When looper

starts

its

forward

stroke,

needle

bar

begins

to

rise

from

its

lowest

position.

During

its

forward

stroke,

looper should

pass

behind

needle

(just

clearing

back

of

needle).

When

needle

bar

reaches

its

highest

position, looper completes

its

forward

stroke

ECCENTRIC

SET

SCREWS

ECCENTRIC-EDGE

OF

CRANK

Fig.

25.

Timing

Needle-Avoiding

Motion

10

and moves

from

rear to front. As needle bar descend^

looper moves backward and

passes

in front of

needle,

(just

clearing

front of

needle).

At end of downward

stroke

of

needle

bar, looper

completes

its

backward

stroke and moves

from

front to rear ready to start its

forward stroke again.

These

correctly

timed movements of looper, from

front to

rear

and

rear

to front,

are

called

the

needle-

avoiding motion of the looper.

To check

the

setting,

turn machine pulley over

toward operator until

eccentric-edge

of crank is down,

as

shown in

Fig.

25. When

centerline

between

the

two

set

screws

on

eccentric

coincides

with

centerline

on

eccentric-edge

of crank,

as

shown by

dosh-line

in Fig.

25,

looper is

set

for maximum amount of

needle-avoid

ing

motion.

To

adjust,

loosen

the

two

eccentric

set

screws

shown in Fig. 25. Rotate eccentric

as

indicoted by

arrow.

Fig.

25, until

needle-ovoidinq

motion

(as

de

scribed above) is obtained. Then tighten the two ec

centric

set

screws.

Loading...

Loading...