DESCRIPTION

Machine 263-1 Is o high

speed,

two thread, chain

stitch, zig-zag machine for attaching

lace

to night

gowns,

slips,

panties,

etc.

SPECIAL

FEATURES

Federal

Stitch

Types

401

and

404.

One needle, one looper.

Needle, Catalog 2796.

Double iooper-threod

take-up.

Tension

releaserfor

looper thread and

needle

thread.

Needle bar has a throw of up to

1/8

inch. Vibrates

both

sides

of

centerline.

Length

of

stitch,

9 to 16

stitches

per

inch.

Drop

Feed.

Needle bar

stroke,

1-3/16

inches..

Clearance

under

presser

foot,

3/16

inch.

Dimensions of bed: Length,

15-3/4

inches;

width, 7

inches;

space

at

right of

needle,

8

inches.

Automatic lubricating system delivers oil to all

principal

bearings.

Oil flow window in

direct

view

of

operation.

Head-end lubrication and oil-return system. Needle

bar bushings lubricated through wicks from arm

shaft

bushings.

Three plain super

finished

bearings

position

and

Support

the

arm

shaft.

Rotary bed

shaft

is

gear

driven.

Knee lifter integral with machine

base

and oil

reser

voir.

Machine provided with

seat

for independent light

fixture mounting.

MACHINE

PULLEY

Machine pulley 146512, for

3/8

inch V-belt, has an

outside

diameter

belt

groove

of

2.9

inches.

Effective

diameter

for

5/16

inch

round

leather

belt

is

2-3/8

inches.

When

in operation,

the

top of the machine pulley

must

always

turn over toward

the

operator.

INSTALLATION

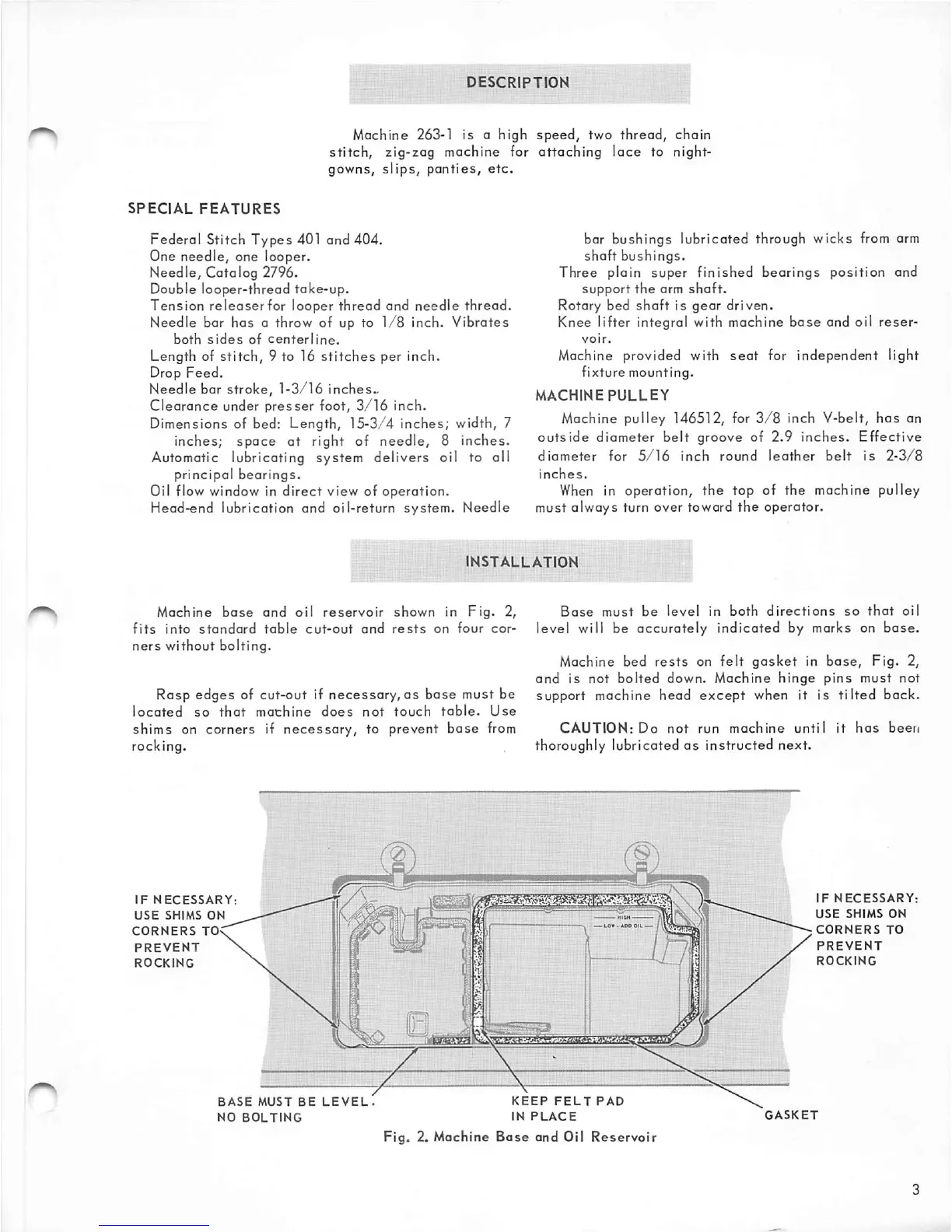

Machine

base

and

oil

reservoir

shown in

Fig.

2,

fits

into

standard

table

cut-out

and

rests

on

four

cor

ners

without

bolting.

Rasp edges of cut-out if necessary, as

base

must be

located

so

that

machine

does

not

touch

table.

Use

shims on corners if

necessary,

to prevent

base

from

rocking.

IF

NECESSARY;

USE

SHIMS

ON

CORNERS

PREVENT

\

ROCKING

L=

Base

must

be

level

in

both

directions

so

that

oil

level will be

accurately

indicated

by marks on

base.

Machine bed

rests

on

felt

gasket

in

base.

Fig. 2,

and

is not

bolted

down.

Machine

hinge

pins

must

not

support machine head

except

when it is

tilted

back.

CAUTION:

Do

not

run

machine

until

it

has

been

thoroughly lubricated

as

instructed

next.

IF

NECESSARY:

USE

SHIMS

ON

CORNERS

TO

PREVENT

ROCKING

BASE

MUST

BE

LEVEL.

NO

BOLTING

KEEP

FELT

PAD

IN

PLACE

GASKET

Fig.

2. Machine

Base

and Oil

Reservoir

Loading...

Loading...