liii-

IT-fSrftafl

LUBRICATION

BEFORE

STARTING

MACHINE:

FILL

TO

HIGH

MARK

CHECK

OFTEN

J

NEVER

ALLOW

OIL

TO

FALL

BELOW

LOW

MARK

OIL

RESERVOIR

HOLDS

1-3/4

PINTS

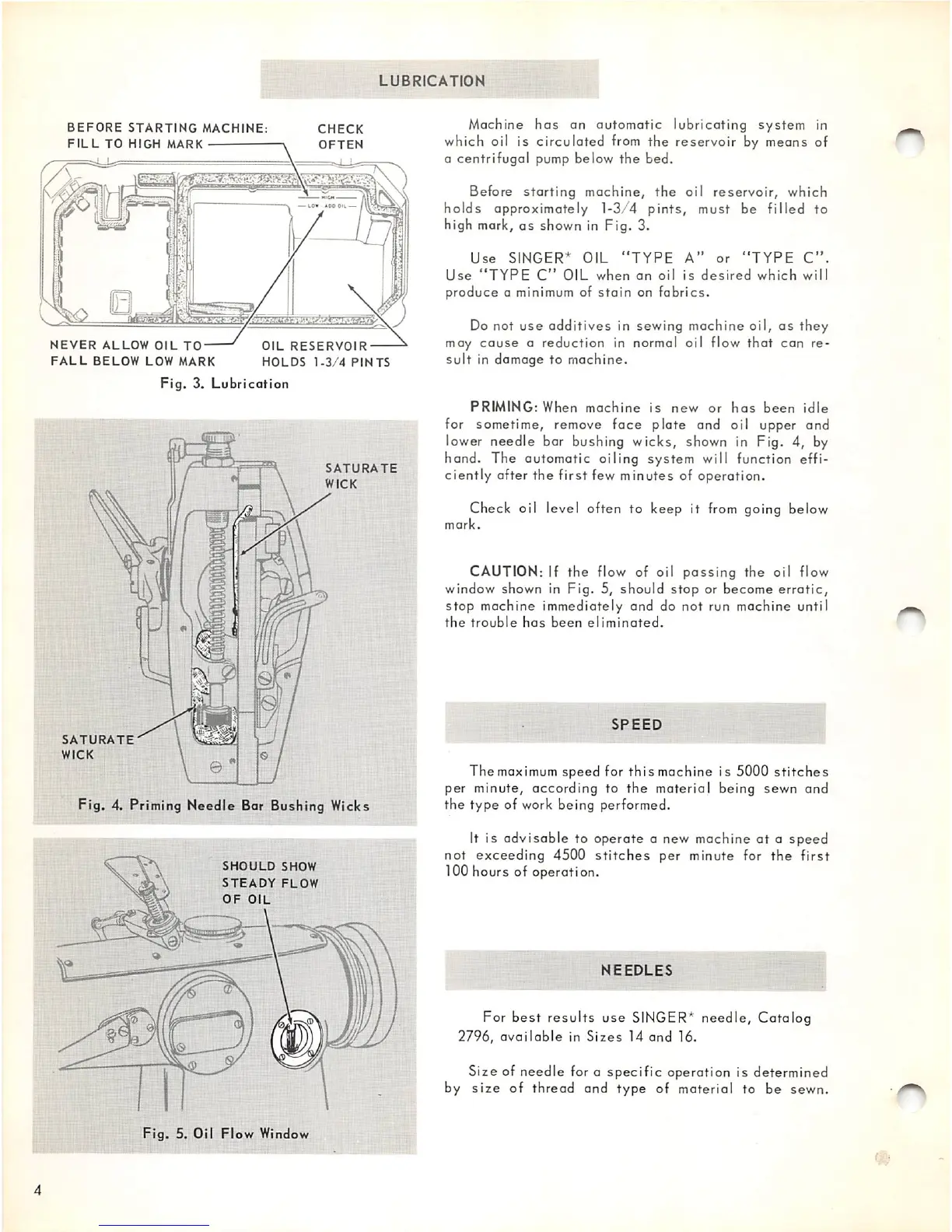

Fig. 3.

Lubrication

SATURATE

WICK

SATURATE

WICK

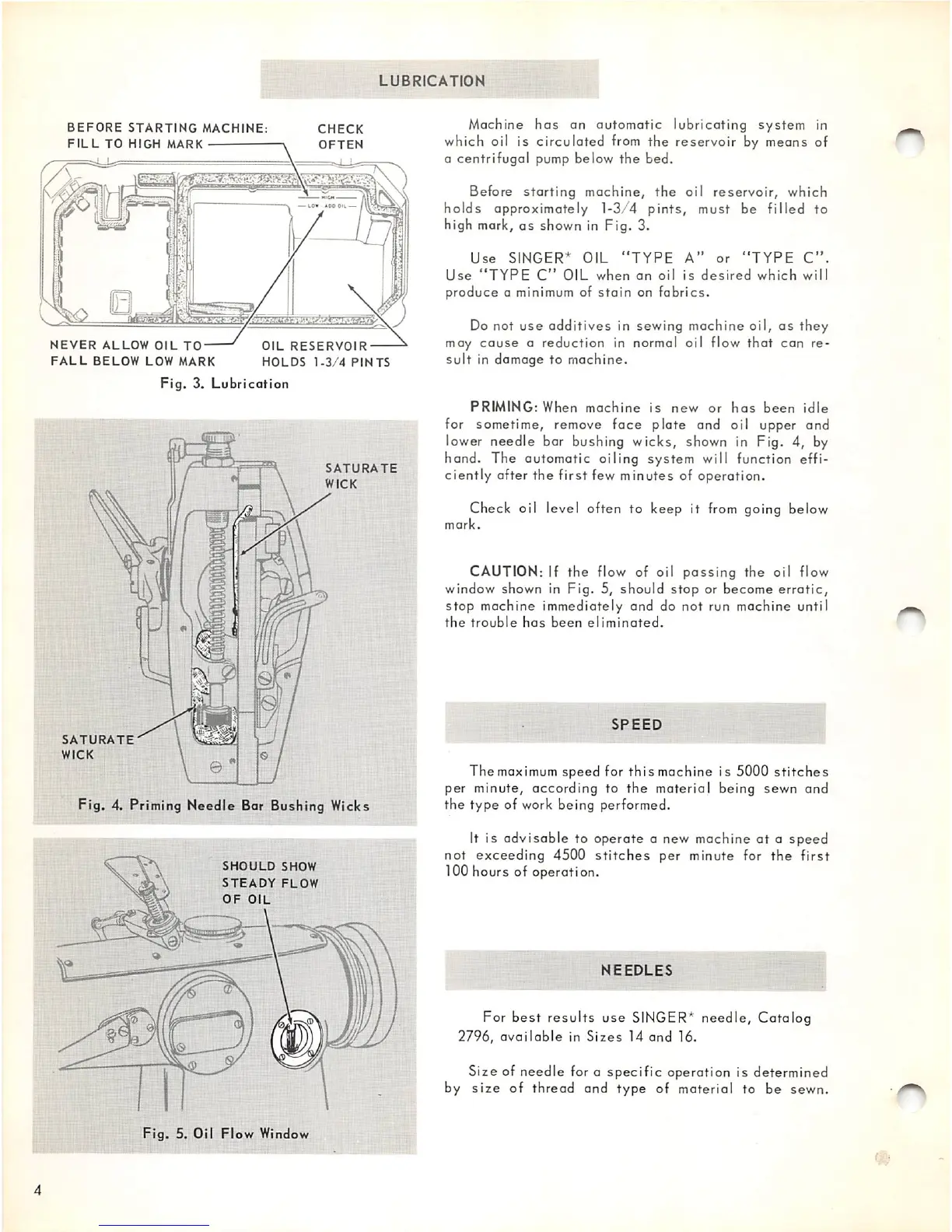

Fig. 4. Priming Needle Bar Bushing

Wtclcs

SHOULD

SHOW

STEADY

FLOW

OF

OIL

Fig.

5. Oil

Flow

Window

Machine

has

on automatic lubricating

system

in

which oil is

circulated

from

the

reservoir by means of

a

centrifugal

pump below

the

bed.

Before

starting

machine,

the

oil reservoir, which

holds

approximately

1-3/4

pints,

must be filled to

high mark, as shown in Fig. 3.

Use

SINGER*

OIL

"TYPE

A"

or

"TYPE

C".

Use

"TYPE

C"

OIL

when

on

oil

is

desired

which

will

produce

a minimum of

stain

on

fabrics.

Do not

use

additives

in sewing machine oil,

as

they

may

cause

a

reduction

in normal oil flow

that

can

re

sult

in damage to machine.

PRIMING:

When

machine

is

new

or

has

been

idle

for sometime, remove

face

plate

and oil upper and

lower needle bor bushing wicks, shown in Fig. 4, by

hand. The automatic oiling

system

will function effi

ciently

after

the

first

few minutes of operation.

Check oil level often to keep it

from

going below

mark.

CAUTION: If

the

flow of oil

passing

the oil flow

window shown in

Fig.

5,

should

stop

or

become

erratic,

stop

machine immediately and do not run machine until

the

trouble

has

been

eliminated.

SPEED

The

maximum

speed

for

this

machine is

5000

stitches

per minute, according to

the

material being sewn and

the type of work being performed.

It is

advisable

to

operate

a new machine

at

a

speed

not

exceeding

4500

stitches

per minute for

the

first

100

hours

of

operation.

NEEDLES

For

best

results

use

SINGER*

needle,

Catalog

2796,

available

in

Sizes

14

and

16.

Size

of

needle

for a

specific

operation

is

determined

by

size

of thread end type of material to be sewn.

Loading...

Loading...