MORE

PRESSURE

LOOSEN

LOCK

NUT

LESS

PRESSURE

Fig.

12.

Adjustment

for

Pressure

on Material

STITCH

LENGTH

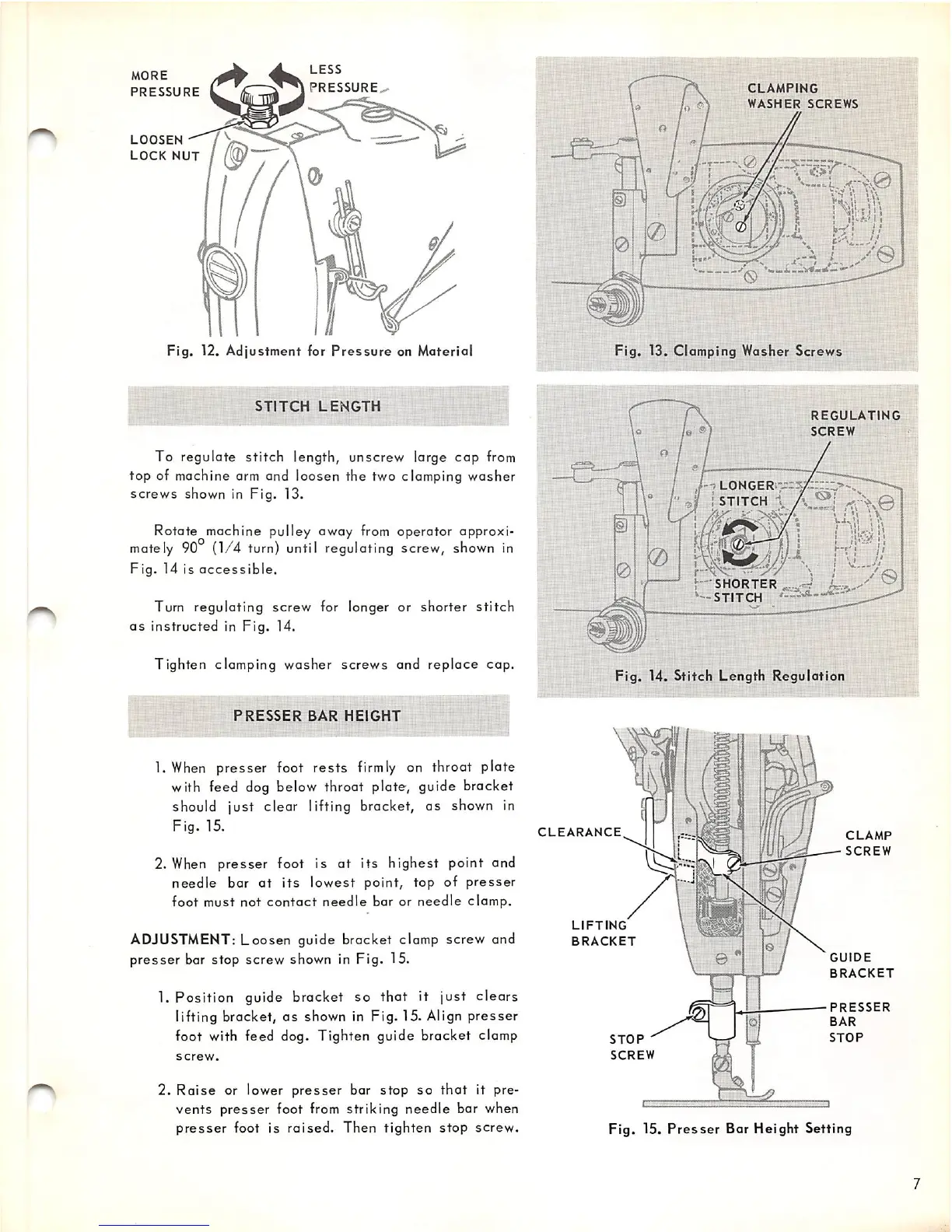

To regulate

stitch

length, unscrew large

cap

from

top of machine arm and loosen the two clamping

washer

screws

shown in Fig. 13.

Rotate machine pulley away from operator approxi

mately 90

(1/4

turn) until regulating screw, shown in

Fig.

14 is

accessible.

Turn regulating

screw

for longer or shorter

stitch

as

instructed

in

Fig.

14.

Tighten clamping washer screws and replace cap.

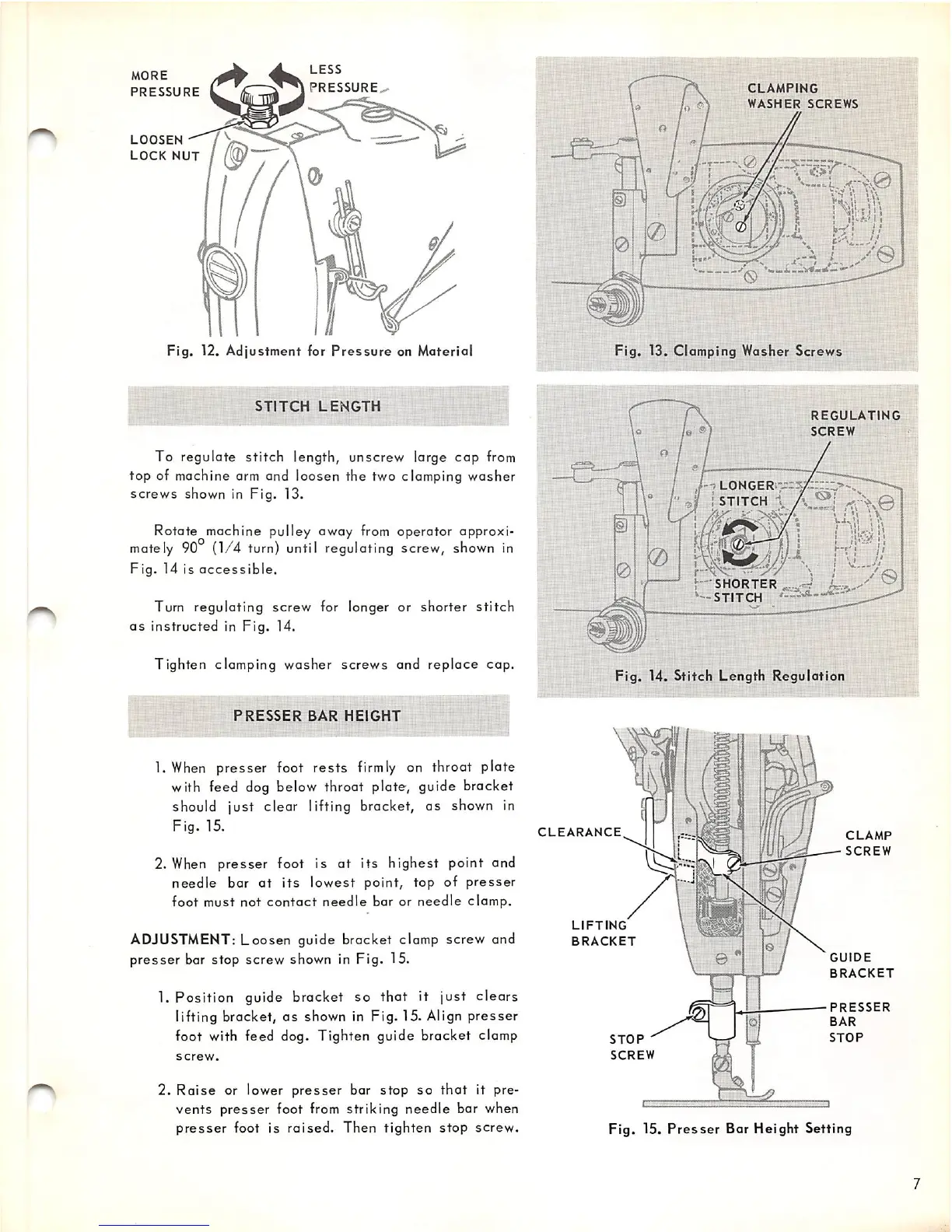

PRESSER

BAR

HEIGHT

1.

When

presser foot

rests

firmly

on throat plate

with feed dog below throat plate-, guide bracket

should just clear lifting bracket, as

shown

in

Fig.

15.

2.

When

presser

foot is at

its

highest point and

needle

bar

at

its

lowest

point, top of

presser

foot must not

contact

needle

bar or

needle

clamp.

ADJUSTMENT: Loosen guide bracket clamp screw and

presser

bar stop screw shown in Fig. 15.

1. Position guide bracket so that it just clears

lifting bracket,

as

shown in Fig. 15. Align

presser

foot with feed dog. Tighten

guide

bracket clamp

screw.

2.

Raise

or lower

presser

bar stop so

that

it pre

vents

presser

foot from striking

needle

bar when

presser

foot is

raised.

Then

tighten

stop

screw.

CLAMPING

WASHER

SCREWS

II

Fig.

13. Clamping Washer

Screws

LONGERi

REGULATING

SCREW

J-SHORTER

'-STITCH

^

Fig. 14. Stitch Length Regulation

CLEARANCE

LIFTING

BRACKET

STOP

SCREW

CLAMP

SCREW

GUIDE

BRACKET

PRESSER

BAR

STOP

Fig. 15.

Presser

Bar Height Setting

Loading...

Loading...