n

FEED

ECCENTRIC

AND

FEED-LIFTING

ECCENTRI

m

FEED

ECCENTRIC

LATER

CONNECTING

ROD

1

SOONER

KEEP

GEARS

IN

MESH

AT

ALL

TIMES

THREE

FEED

ECCENTRIC

SCREWS

FEED-LIFTING

ECCENTRIC

THREE

FEED-LIFTING

ECCENTRIC

SCREWS

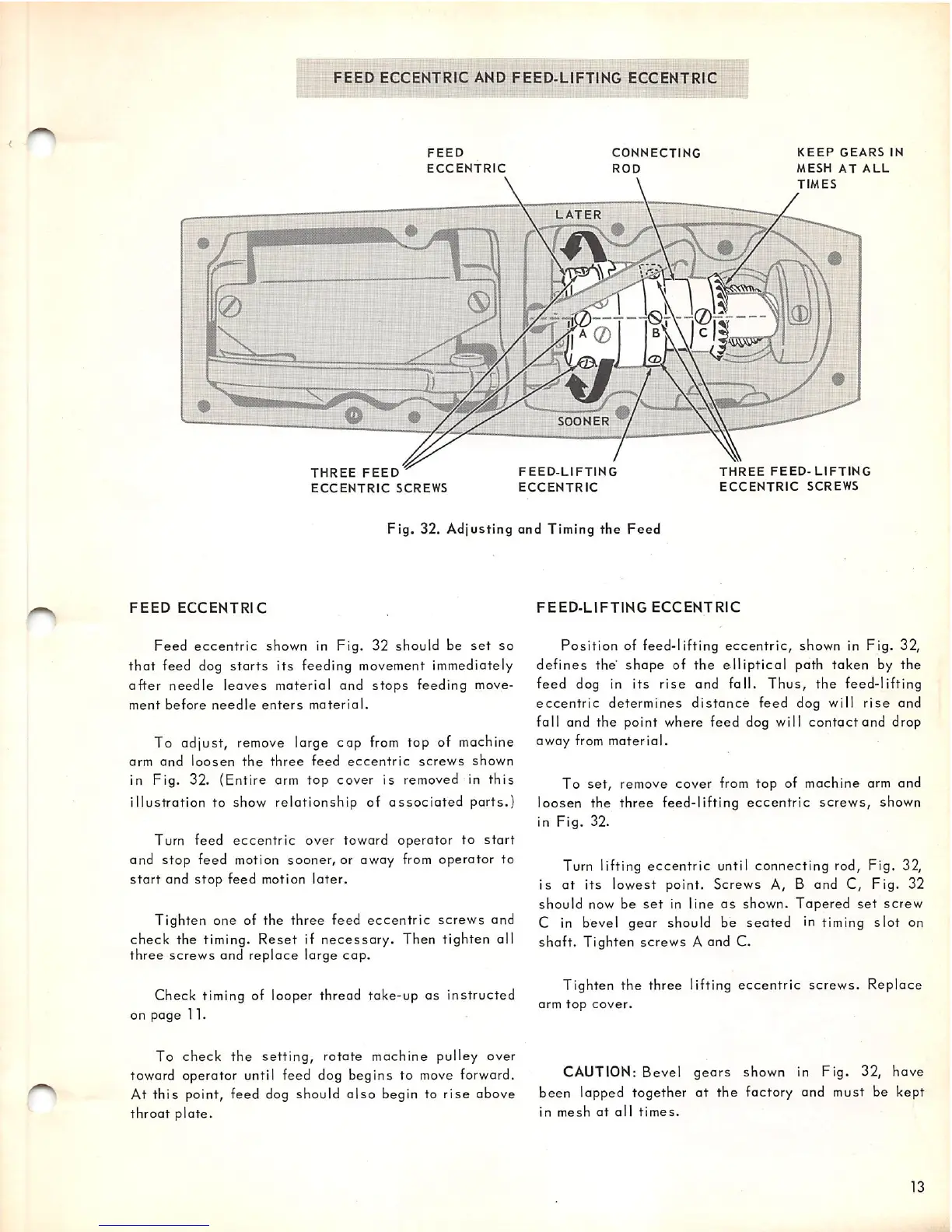

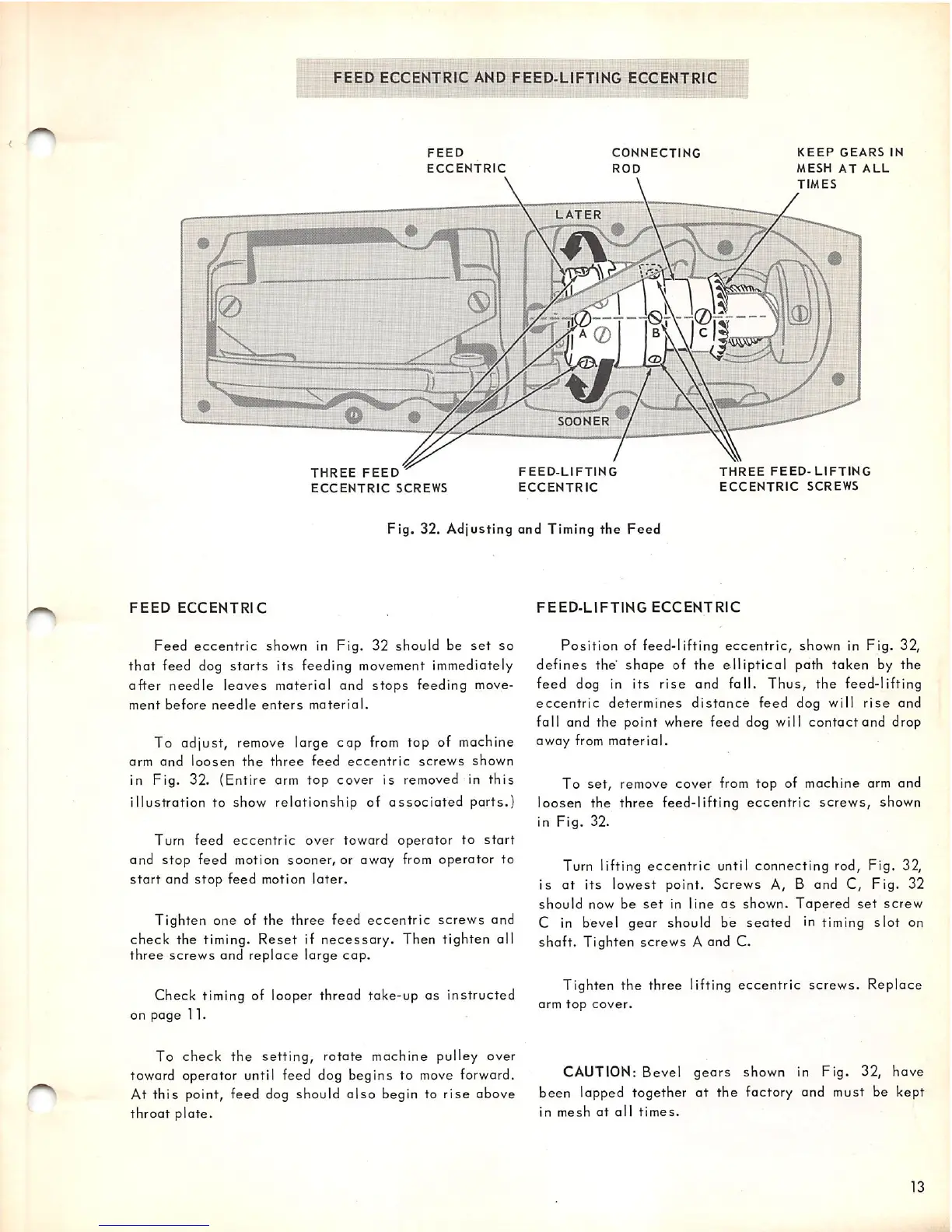

Fig.

32.

Adjusting

and

Timing

the

Feed

FEED

ECCENTRIC

Feed

eccentric

shown in

Fig.

32

should

be

set

so

that

feed dog

starts

its feeding movement immediately

after

needle

leaves

material

and

stops

feeding move

ment

before

needle

enters

material.

To adjust, remove large cap

from

top of machine

arm

and

loosen

the

three

feed

eccentric

screws

shown

in Fig. 32. (Entire arm top cover is removed in

this

illustration

to show

relationship

of

associated

ports.)

Turn feed

eccentric

over

toward

operator

to

start

and

stop

feed motion

sooner,

or

away

from

operator

to

start

and

stop

feed motion

later.

Tighten one of the three feed

eccentric

screws

and

check

the timing.

Reset

if

necessary.

Then tighten all

three

screws

and

replace

large

cap.

Check

timing of looper thread

take-up

as

instructed

on

page

11.

To

check

the

setting,

rotate machine pulley over

toward operator until feed dog begins to move forward.

At

this

point, feed dog should

also

begin to

rise

above

throat

plate.

FEED-LIFTING

ECCENTRIC

Position

of

feed-lifting

eccentric,

shown in

Fig.

32,

defines

the

shape

of

the

elliptical

path

taken

by

the

feed

dog in its

rise

and fall.

Thus,

the feed-lifting

eccentric

determines

distance

feed dog will

rise

and

fall

and

the

point where

feed

dog will

contact

and

drop

away

from

material.

To

set,

remove

cover

from

top

of

machine

arm and

loosen the three feed-lifting

eccentric

screws,

shown

in

Fig.

32.

Turn lifting

eccentric

until connecting rod. Fig. 32,

is

at

its

lowest point. Screws A, B and C,

Fig.

32

should

now be

set

in

line

as

shown.

Tapered

set

screw

C in bevel

gear

should be

seated

in timing

slot

on

shaft.

Tighten

screws

A and C.

Tighten

the

three lifting

eccentric

screws.

Replace

arm

top

cover.

CAUTION: Bevel

gears

shown in

Fig.

32, have

been lapped together

at

the

factory and must be kept

in

mesh

at

all

times.

13

Loading...

Loading...