HEIGHT

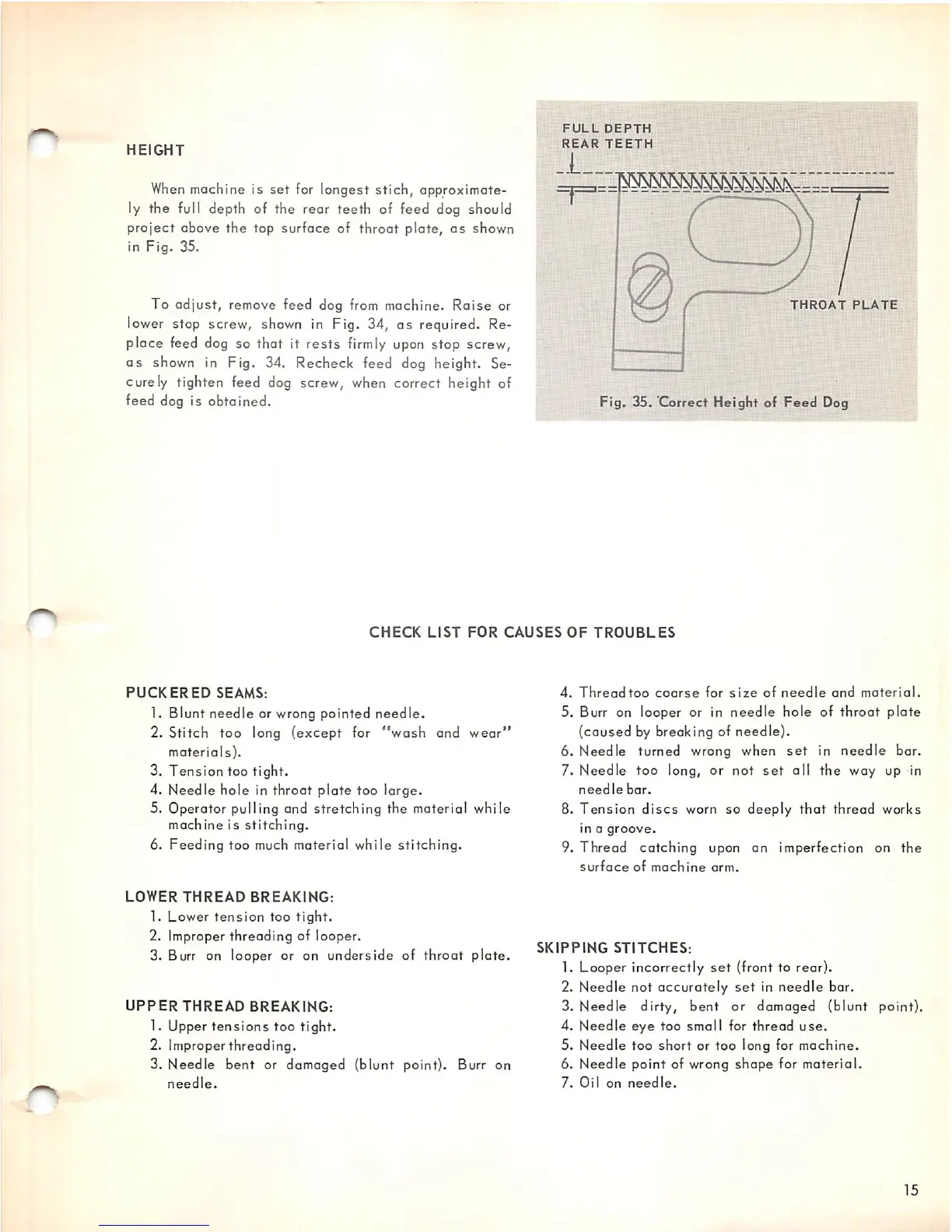

When

machine is

set

for longest

stich,

approximate

ly the full depth of the rear teeth of feed dog should

project

above

the

top surface of throat plate,

as

shown

in

Fig.

35.

To

adjust,

remove feed dog from machine.

Raise

or

lower stop screw, shown in Fig. 34, as required. Re

place feed dog so that it

rests

firmly upon stop screw,

as

shown in Fig. 34. Recheck feed dog height. Se

curely tighten feed dog screw, when correct height of

feed dog is

obtained.

FULL

DEPTH

REAR

TEETH

THROAT

PLATE

Fig. 35. Correct Height of

Feed

Dog

CHECK

LIST

FOR

CAUSES

OF

TROUBLES

PUCKERED

SEAMS:

1. Blunt

needle

or wrong pointed

needle.

2. Stitch too long

(except

for

"wash

and

wear"

materials).

3.

Tension

too

tight.

4. Needle hole in throat

plate

too large.

5. Operator pulling and

stretching

the material while

machine is

stitching.

6. Feeding too much material while

stitching.

LOWER

THREAD

BREAKING:

1.

Lower

tension

too

tight.

2. Improper

threading

of looper.

3. Burr on looper or on underside of

throat

plate.

UPPERTHREAD

BREAKING:

1. Upper

tensions

too tight.

2. Improperthreading.

3.

Needle

bent

or

damaged

(blunt

point). Burr on

needle.

4.

Thread

too

coarse

for

size

of

needle

and

material.

5. Burr on looper or in

needle

hole of

throat

plate

(caused

by breaking of needle).

6. Needle turned wrong when

set

in

needle

bar.

7. Needle too long, or not

set

all

the

way up in

needle

bar.

8.

Tension

discs

worn so deeply

that

thread works

in a

groove.

9.

Thread

catching

upon an

imperfection

on

the

surface

of

machine

arm.

SKIPPING

STITCHES:

1. Looper incorrectly

set

(front to rear).

2. Needle not

accurately

set

in

needle

bar.

3. Needle dirty,

bent

or damaged (blunt point).

4.

Needle

eye

too

small

for

thread

use.

5.

Needle

too

short

or

too

long for

machine.

6.

Needle

point

of wrong

shape

for

material.

7.

Oil

on

needle.

15

Loading...

Loading...