1L

..

~~~(008

..

009

..

0010) I

Thread

tension asm. (Fig.8

..

Fig.9

..

Fig.10)

008

Fig.8

009

Fig.9

m~*n~~~(008~~):

~~~~~~~~*n~*o

*~*n~~~(009~~):

~~~~~~~~*n~*o

*m~~**

(OOIOJi)f~)

19tilt~~~*10Co

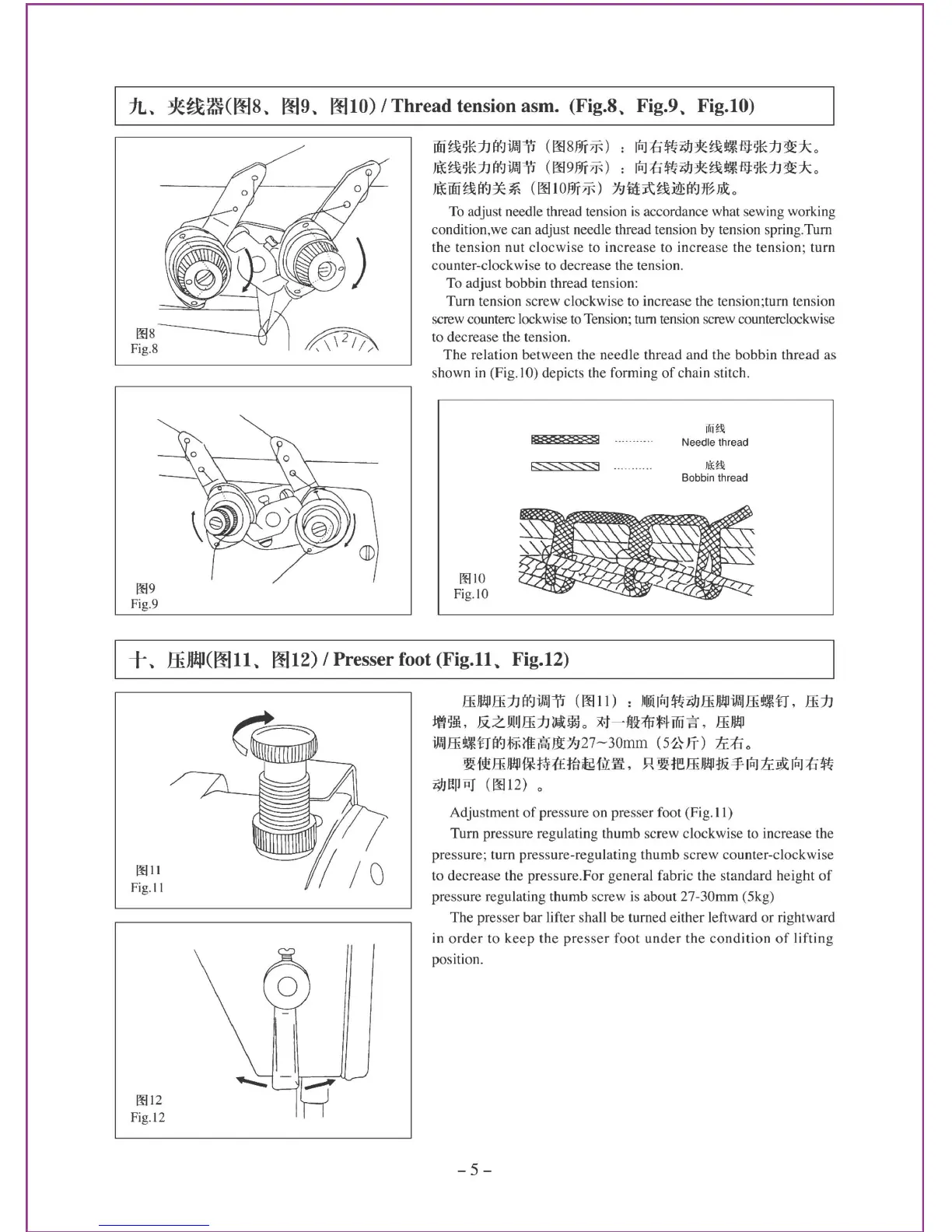

To

adjust needle thread tension

is

accordance what sewing working

condition,we can adjust needle thread tension

by

tension spring.Tum

the tension nut

clocwise

to increase to increase the tension; turn

counter-clockwise to decrease the tension.

To adjust bobbin thread tension:

Turn tension screw clockwise to increase the tension;turn tension

screw counterc lockwise to Tension; tum tension screw counterclockwise

to decrease the tension.

The relation between the needle thread and the bobbin thread as

shown

in

(Fig.l 0) depicts the forming

of

chain stitch.

0010

Fig.lO

f{ij~

Needle thread

}ij;~

Bobbin thread

+

..

ffiJJ141(0011

..

0012) I Presser foot (Fig.11

..

Fig.12)

0011

Fig.

II

0012

Fig.l2

ffi}l!pffin~~~

(0011)

:

J®i~~~ffilm!~ffit~n.

ffin

*~·

&~~ffin~-0~

H~Mffi~.

ffilm!

~ffit~tJ~;J>ifliWJil1927-30mm

(5*

JT)

tr.~

o

¥Rffilml~~~m~ffiW,

R¥reffilm!fi~~tr.~~~~

~

ep

l=iT

( m

12)

0

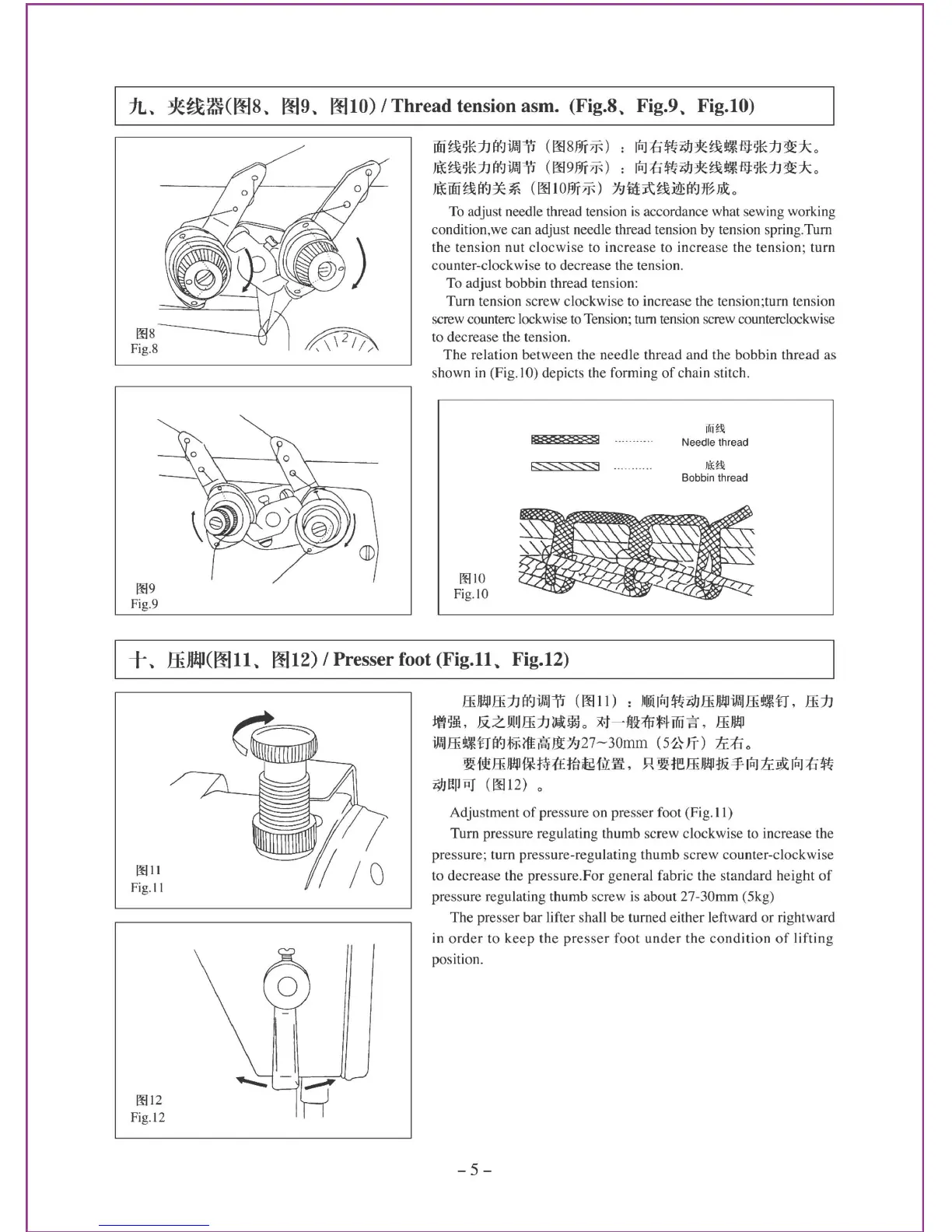

Adjustment

of

pressure on presser foot (Fig.

II)

Turn pressure regulating thumb screw clockwise to increase the

pressure; turn pressure-regulating thumb screw counter-clockwise

to decrease the pressure.For general fabric the standard height

of

pressure regulating thumb screw is about 27-30mm (5kg)

The presser bar lifter shall be turned either leftward or rightward

in

order

to

keep

the

presser

foot

under

the

condition

of

lifting

position.

-5-

Loading...

Loading...