+

/'\

..

ftfffi6ltB9iJJTi(l!l20)

I Adjustment

of

the height

of

needle bar (Fig.20)

0020

Fig.20

ftJtiTVX7;t;JL*Bof,

PJffl*ff

J:ff.J~Ijt&,

*ff:f±r~-~Bof,

ttff

J:~Jt&Mx.tilttffrM~I¥1r~oo(~noo2orJT7F),

j!f'fJM:

{jt~

T*ffff.J~}jto

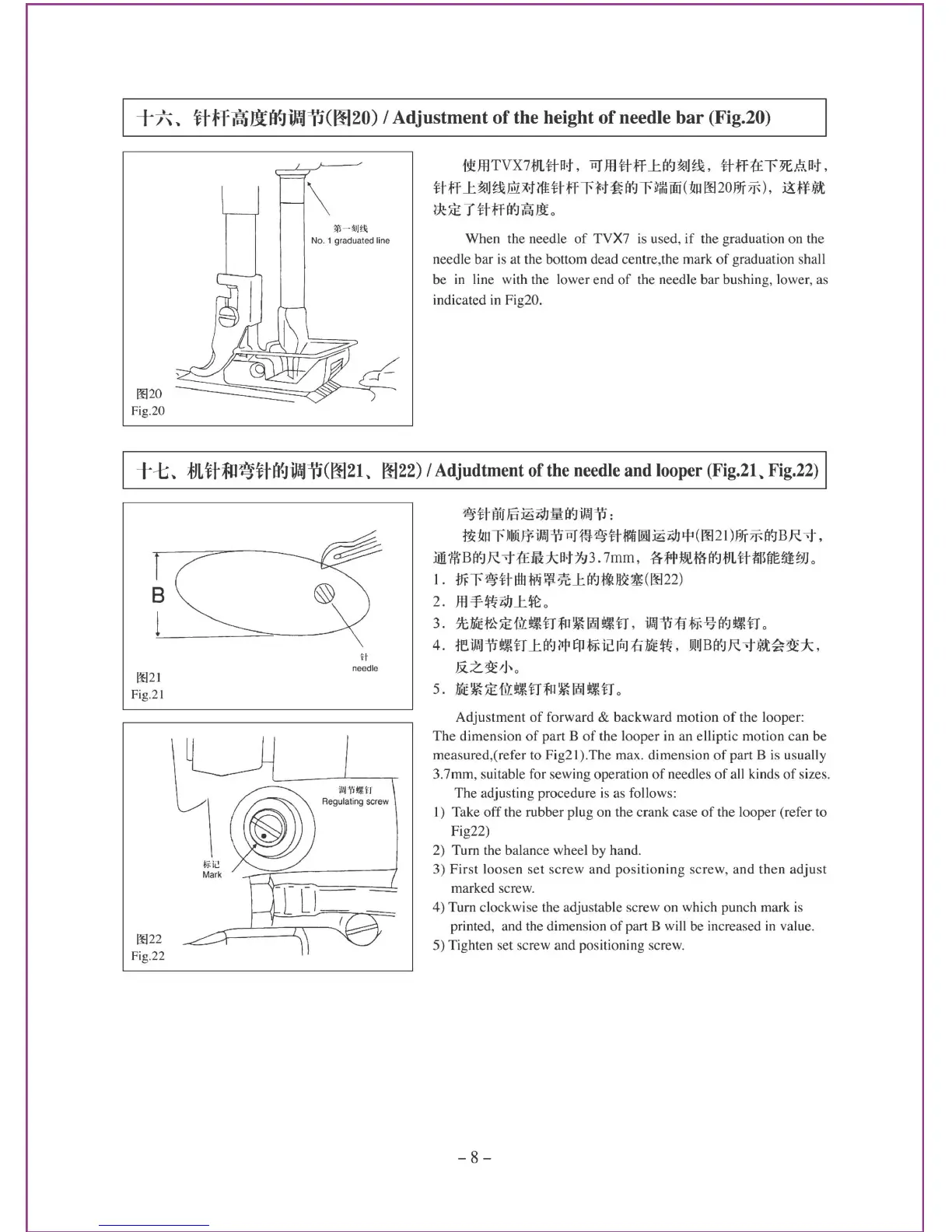

When the needle

of

TVX7 is used,

if

the graduation on the

needle bar

is

at the bottom dead centre,the mark

of

graduation shall

be

in

line with the lower end

of

the needle bar bushing, lower, as

indicated

in

Fig20.

+-1::

..

lJLltf;JJ~ltl'f.JifnJi1(0021..

0022)

I

Adjudtment

of

the

needle

and

looper

(Fig.21,.

Fig.22)

8

l

0021

Fig.21

0022

Fig.22

tt

needle

~ *

ffrJ

J§

~

l;IJ:fll¥1

00

i'i :

~~llrllllJi}'fiffiJi'iPJ1~~*Wffml~l;IJt:f:t(0021

)fi]f7FI¥JBR

>t,

im1tBI¥JR>t:f±Mi*.B1793.

7mm,

~;fttlm!~ff.J;t;JL*:mttE:~~lJJo

1.

tfir~ttDtlm'lJ~J:I¥11t~*(0022)

2.

Jtl=f~z.;J)J:$&:0

3.

~~~~~~n~~~~n.OOi'i~~%1¥J~Uo

4.

ffiiffili'i~UJ:I¥1~~~~~~~~.

~Bff.JR-.J-8~~*·

OCZ~Ij'\0

s.

~~~~~'-Ufo~~~'-n

0

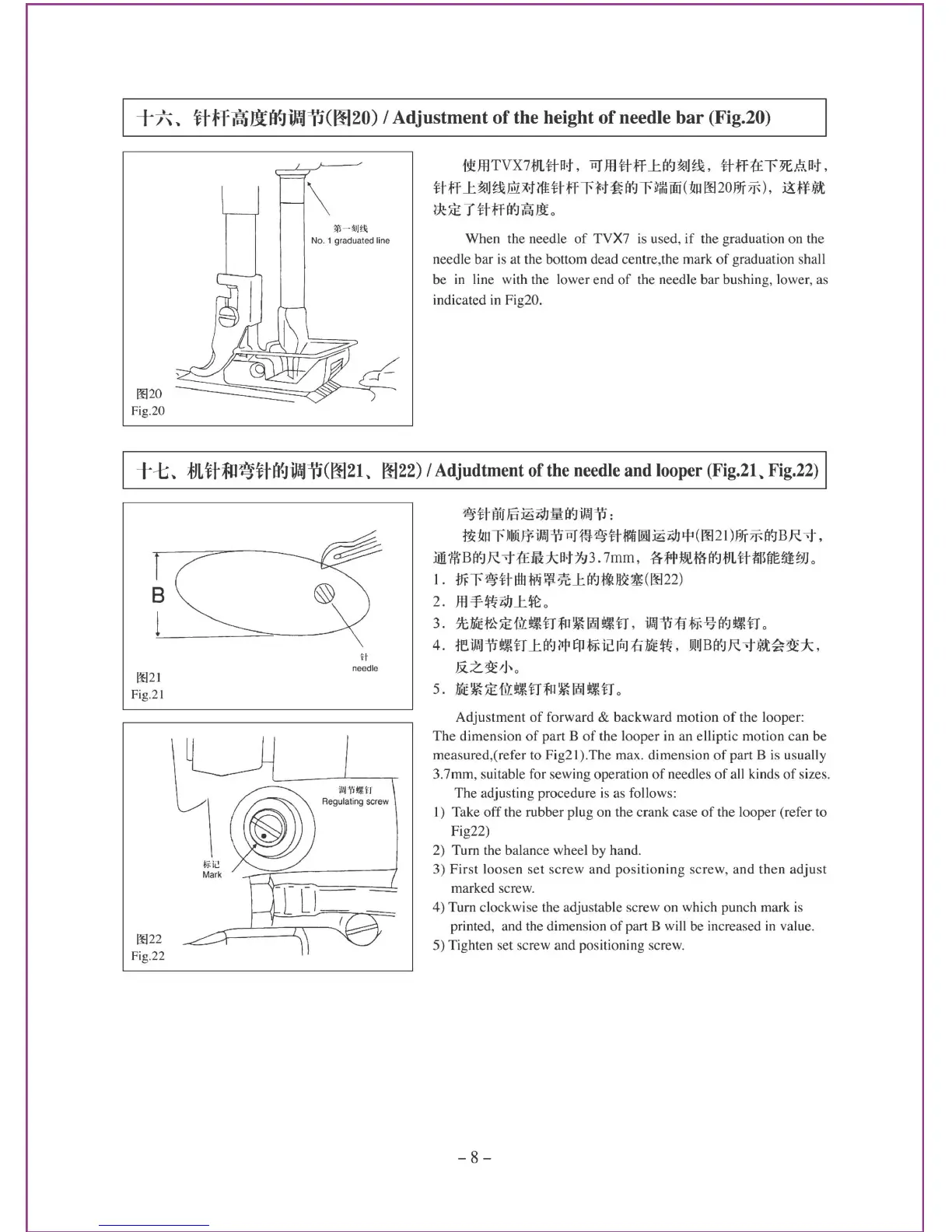

Adjustment

of

forward & backward motion

of

the looper:

The dimension

of

part B

of

the looper in an elliptic motion can be

measured,( refer to Fig21

).

The max. dimension

of

part B

is

usually

3.7mm, suitable for sewing operation

of

needles

of

all kinds

of

sizes.

The adjusting procedure

is

as follows:

1)

Take off the rubber plug on the crank case

of

the looper (refer to

Fig22)

2) Turn the balance wheel by hand.

3) First loosen set screw and positioning screw, and then adjust

marked screw.

4) Turn clockwise the adjustable screw on which punch mark

is

printed, and the dimension

of

part B will be increased in value.

5) Tighten set screw and positioning screw.

-8-

Loading...

Loading...