+

!\..,.

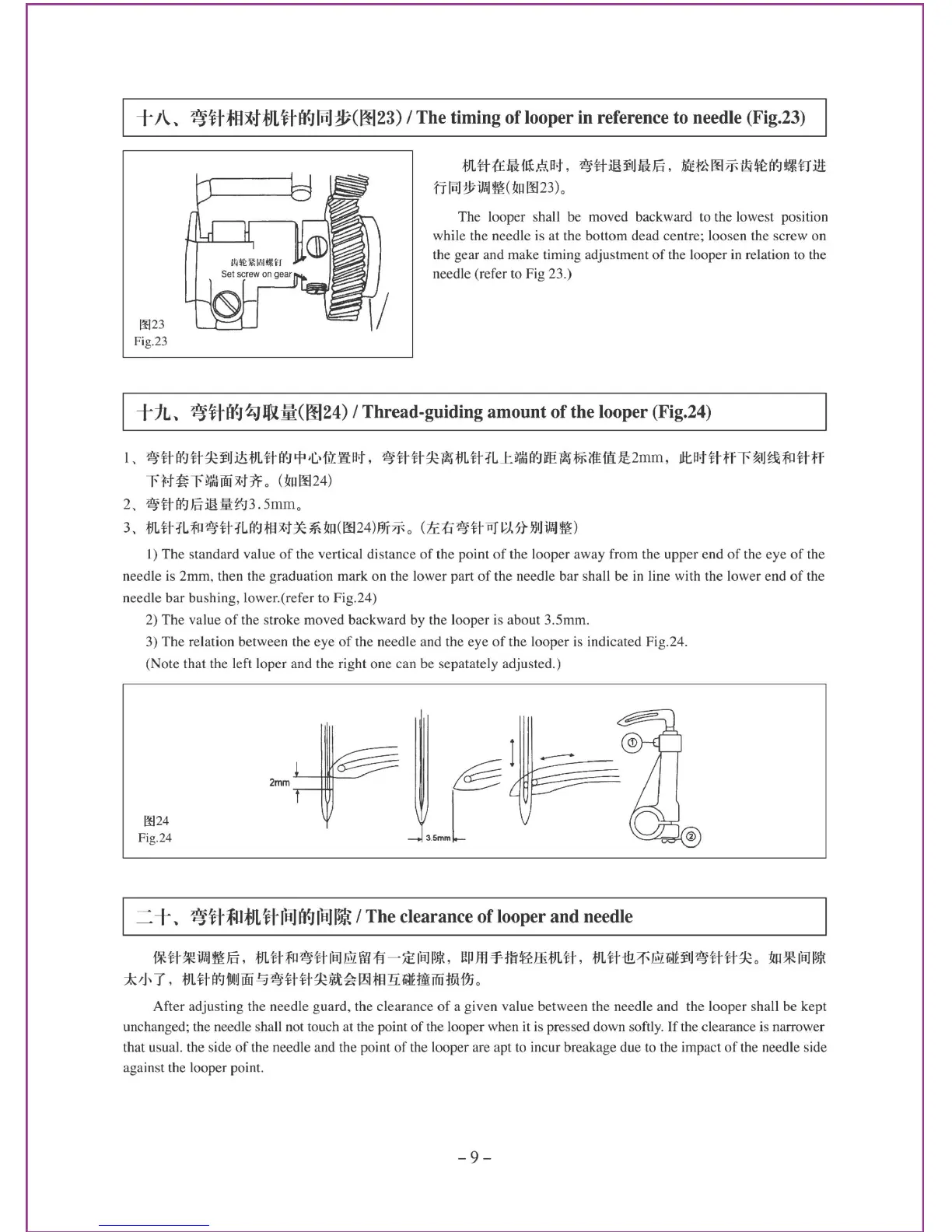

~ft*H~f)Lft(J9~~(0023)

I The timing

of

looper in reference to needle (Fig.23)

0023

Fig.23

mtta•~~at.~ttm~am.•~oo~m~~¥-J•nm

fi

1"1

tviffil~(-tln

0023)0

The looper shall be moved backward to the lowest position

while the needle is at the bottom dead centre; loosen the screw on

the gear and make timing adjustment

of

the looper in relation to the

needle (refer to Fig 23.)

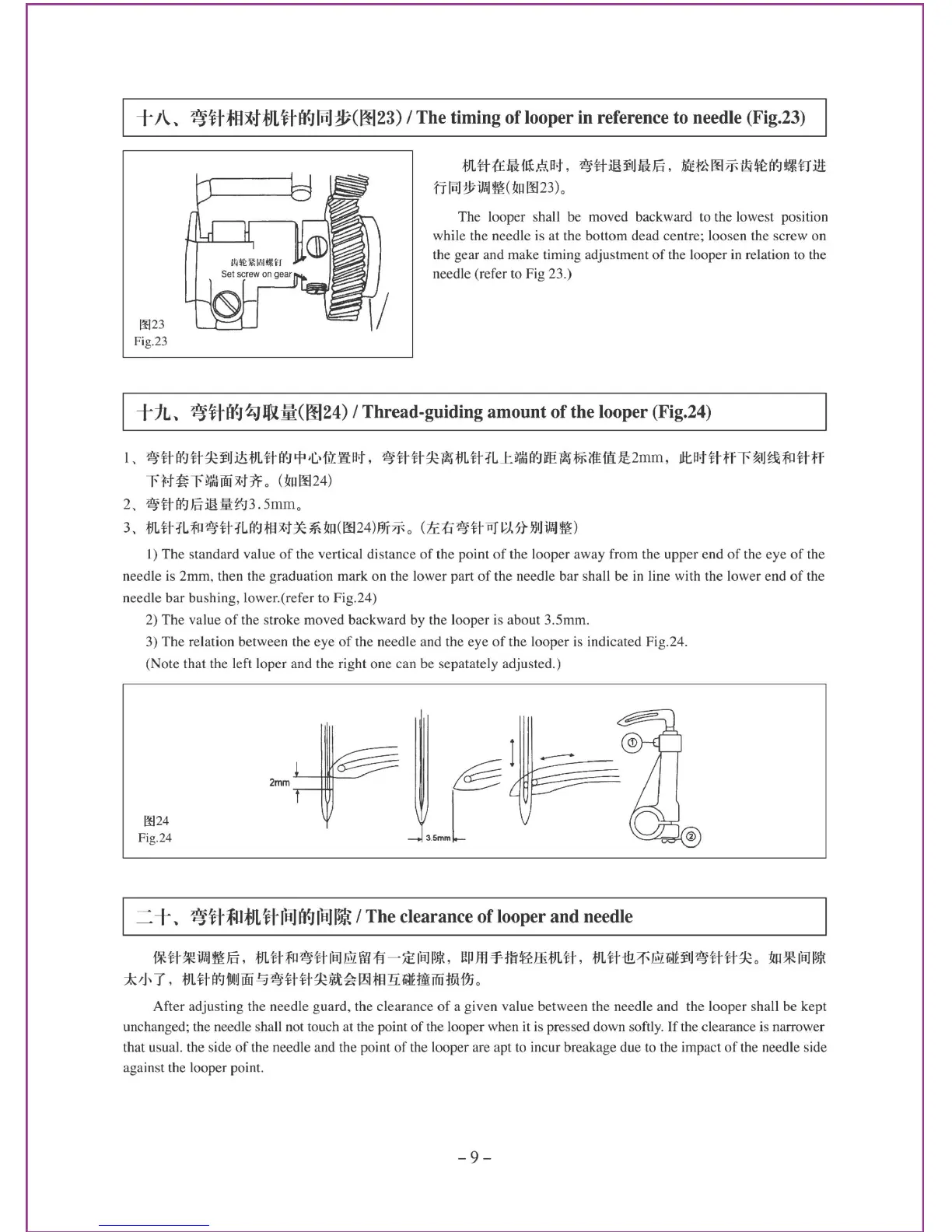

+11,.

~ftB9-t.Jn:E:C0024)

I Thread-guiding amount

of

the looper (Fig.24)

1,

~tti¥-Jtt~~~J:ititrttti¥-J!=f•l)fll:JiB>t,

~tttt~~*JLtf":fLJ:ltffiii¥-J~E~tT-<lfi:J!:2mm,

!ltB>tttffr~IJ~~ottff

r~t~rliffiloox.J1f

0

ctmrB24)

2,

~tti¥-JJ§miH'.J3.5mmo

3,

fJLtt:fL~o~tt:fLI¥-JfBX>f*

~

-tln(rB24)PJf~

o

(li:1i~tt

PI

LV,

Jt~ljiffil~)

1)

The standard value

of

the vertical distance

of

the point

of

the looper away from the upper end

of

the eye

of

the

needle is 2mm, then the graduation mark on the lower part

of

the needle bar shall be in line with the lower end

of

the

needle bar bushing, lower.(refer to Fig.24)

2) The value

of

the stroke moved backward by the looper is about 3.5mm.

3) The relation between the eye

of

the needle and the eye

of

the looper is indicated Fig.24.

(Note that the left Ioper and the right one can be sepatately adjusted.)

0024

Fig.24

2mm

~]

,_[

=

+,.

~ftf;n;f;)Lftfii)(J9(ii]~t

I The clearance

of

looper and needle

**•~~m.mtt~~ttoo@m~

-

~oog,

~m~m~ffimtt.mtt~~@m~~**~o~*oog

t/J\

7.

mtt~¥-Jimtloo

Ei~tttt~~~~*B!LTitttirmtJJlf%

0

After adjusting the needle guard, the clearance

of

a given value between the needle and the looper shall be kept

unchanged; the needle shall not touch at the point

of

the looper when it

is

pressed down softly.

If

the clearance

is

narrower

that usuaL the side

of

the needle and the point

of

the looper are apt to incur breakage due to the impact

of

the needle side

against the looper point.

-9-

Loading...

Loading...