Do you have a question about the Sisu Diesel 420D and is the answer not in the manual?

Lists specifications for cylinder liners, such as protrusion and outer diameter.

Details specifications for the cylinder head, including height and valve guide dimensions.

Lists specifications for the camshaft, including bearing journal diameters and clearances.

Details specifications for timing gears, including tooth backlash and marks.

Lists specifications for connecting rods, including pin bushing and big end bearing dimensions.

Details oil pressure requirements and specifications for the lubricating oil pump.

Provides specifications for the coolant pump on 320 and 420 engines, including bearing and shaft diameters.

Lists specifications for turbochargers, including shaft end float and radial clearance.

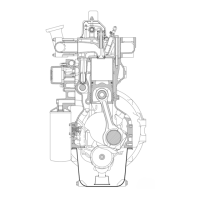

Describes the cylinder block, its function, and key features like wet liners and camshaft location.

Details the cylinder head construction for different engine models, bolt tightening, and valve guides.

Describes the turbocharger operation, lubrication, cooling, and by-pass system.

Details the process of fitting cylinder liners, including checking paint deposit and liner height.

Explains how to change the crankshaft rear oil seal, including cleaning and potential spacer ring use.

Explains how to machine valve seats using milling cutters and the correct angles.

Explains how to clean and check the crankshaft for wear and journal clearance.

Provides instructions for fitting the crankshaft, including bearing lubrication, end float check, and main bearing cap tightening.

Details the procedure for changing the crankshaft pulley/vibration damper and setting injection timing.

Explains how to change connecting rod bearings, including piston pin bushing and big end bearing procedures.

Details the process of fitting the piston with the connecting rod, including bearing lubrication and tightening.

Explains how to fit the flywheel, including cleaning surfaces, using guide pins, and tightening screws.

Details how to recondition the oil relief valve, including cleaning and checking parts.

Details the reconditioning of the coolant pump for 320/420 engines, including disassembly and part removal.

Explains the reconditioning of coolant pumps with separate ball bearings for various engine models.

Details how to check inlet and exhaust pipes for leaks, flatness, and damage.

Explains how to diagnose turbocharger faults by visually inspecting wheels and checking oil leaks.

Technical data for Bosch A/P inline fuel injection pumps, including types, orders, and oil fillings.

Lists tightening torques for fuel system components like injection pump gears and injectors.

Explains how to adjust fuel injection timing by rotating the injection pump.

Explains how to fit the Bosch-A injection pump, including o-ring checks, alignment, and bleeding.

Explains how to adjust the engine idling speed using specific screws.

Explains how to inspect injectors, including cleaning, checking opening pressure, and spray pattern.

Explains how to bleed the fuel filter for the distributor pump system.

Explains how to fit the Stanadyne injection pump and adjust its injection timing.

Provides specifications for Magneti Marelli and CAV alternators, including voltage and output.

| Brand | Sisu Diesel |

|---|---|

| Model | 420D |

| Category | Engine |

| Language | English |