7

.

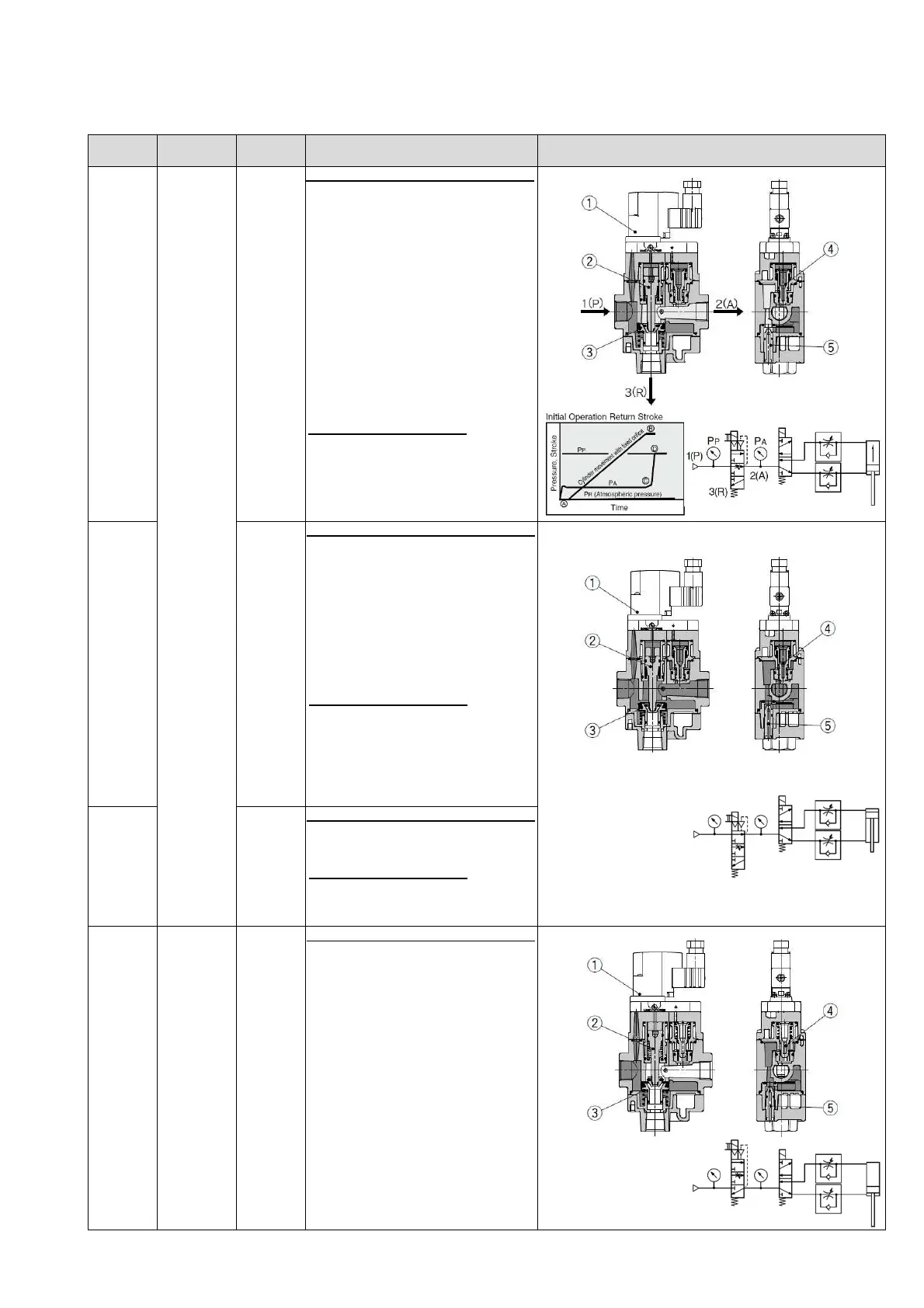

Working Principle

Working

conditions

Pilot valve

Pressure

conditions

Operation description

Internal construction/Cylinder actuation circuit

(Meter-out control) example

Low

Speed

air supply

ON

P

S

> P

A

Operation description of the soft start-up valve

When the pilot valve ① is energized or

turned ON manually, the spool ② is

pushed down due to the pilot air and

gets into contact with the valve ③,

closing the flow passage to port 3 (R). At

this time, force that pushed the valve ③

≧ force that pushed down the spool ②

Therefore, the flow passage from the

valve ③ to port 2 (A) is still closed.

Furthermore, the piston ④ is pushed

down due to the pilot air, and the flow

passage from the needle ⑤ to port 2

(A) opens.

And then, the air pressure whose flow

rate is adjusted by the needle ⑤ flows

to port 2 (A).

Description of cylinder actuation

The meter-in control of the needle ⑤

slowly moves the cylinder from A to B.

P

P

: Inlet pressure

P

A

: Outlet pressure

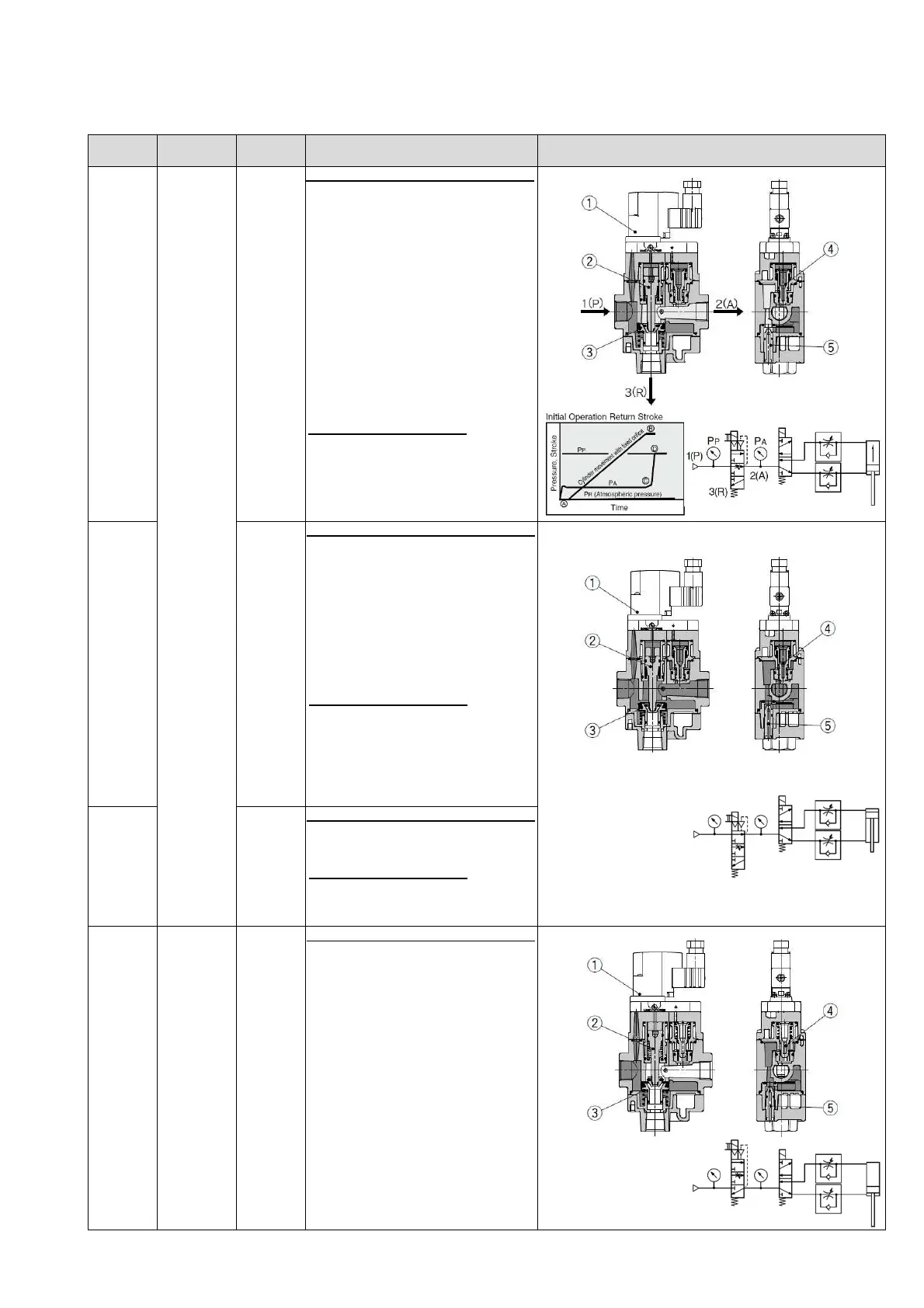

High

Speed

air supply

P

S

≦P

A

Operation description of the soft start-up valve

When the outlet side is filled with

pressure supplied from the needle ⑤,

P

A

increased. When P

A

exceeds the

specified pressure, the force that

pushed up the valve ③ becomes

smaller than t

he force that pushed down

the spool ②. Then, the valve ③ is

pushed down, opening the flow

passage, and pressure is supplied to

port 2 (A).

Description of cylinder actuation

When P

S

< P

A

after the cylinder reaches

B, the mail calve fully opens and P

A

increase rapidly as shown C to D and

becomes the same pressure as P

P

.

P

S

:

Pressure for switching to rapid air supply

Normal

operation

P

S

≒P

A

Operation description of the soft start-up valve

The valve ③ holds the fully open

condition.

Description of cylinder actuation

The cylinder operation is controlled by a

meter-out circuit on the cylinder side.

Exhaust

OFF

-

Operation description of the soft start-up valve

When the pilot valve ① is turned OFF,

the pilot air of the spool ②

from the pilot valve ①, and the spool ②

and valve ③ are returned upward due

to the spring. This opens the flow

passage to the port 3 (R), exhausting

the air pressure on the port 2 (A)

side.

The pilot air of the piston ④ is also

exhausted from the pilot valve ①, and

the piston ④ is returned upward due to

the spring, closing the flow passage

from needle ⑤.

-25-

Loading...

Loading...