Adjustment

Caution

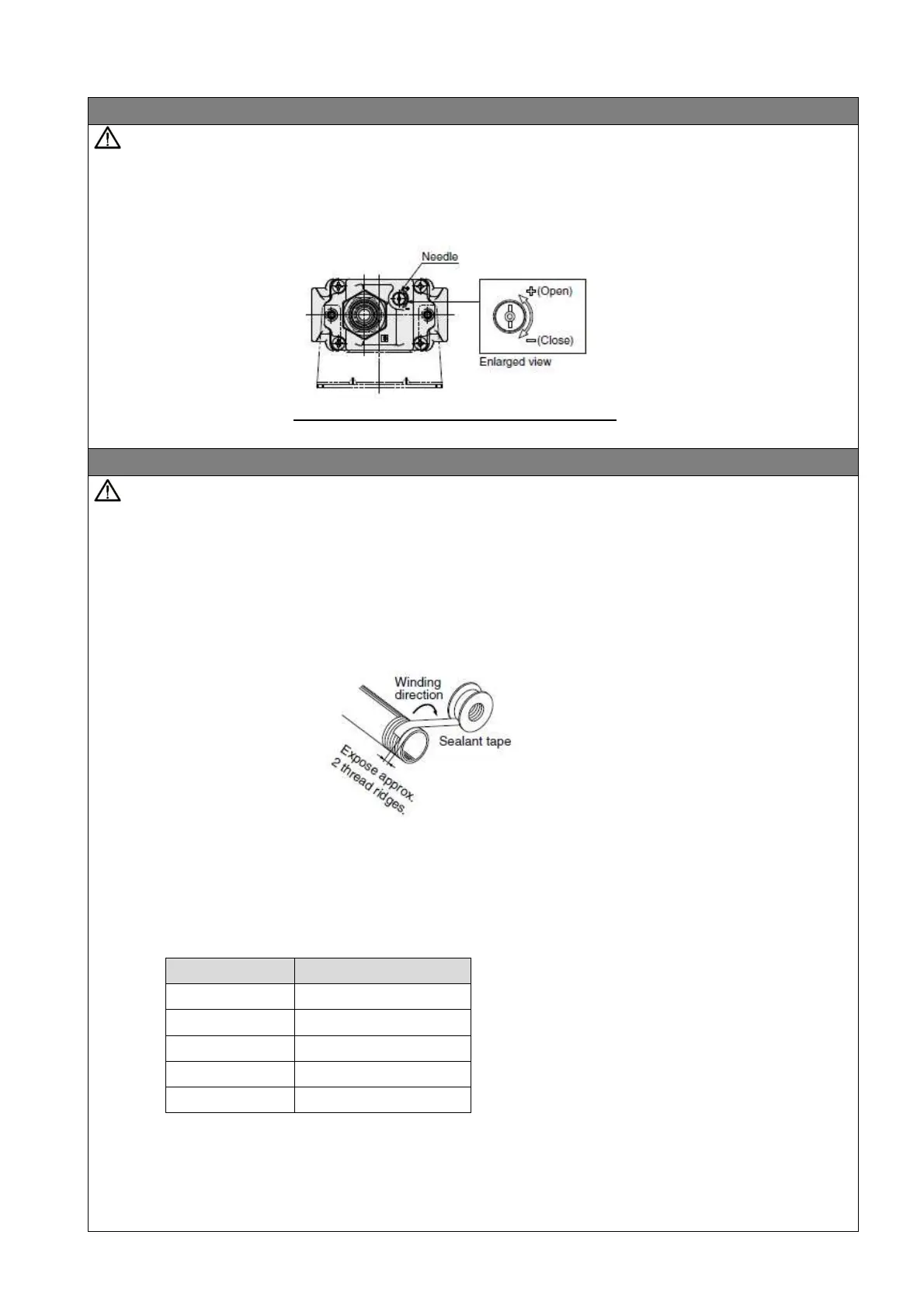

1. Needle operation of low speed air supply

To perform the initial speed adjustment of the outlet side actuator, supply air from this

product’s inlet side and turn ON the pilot valve. Then, rotate the needle

counterclockwise from the fully closed position.

Product bottom surface (exhaust port side)

Piping

Warning

1. Preparation before piping

Before piping is connected, it should be thoroughly blown out by air (flushing) or washed

to remove chips, sutting oil and other debris from inside the pipe.

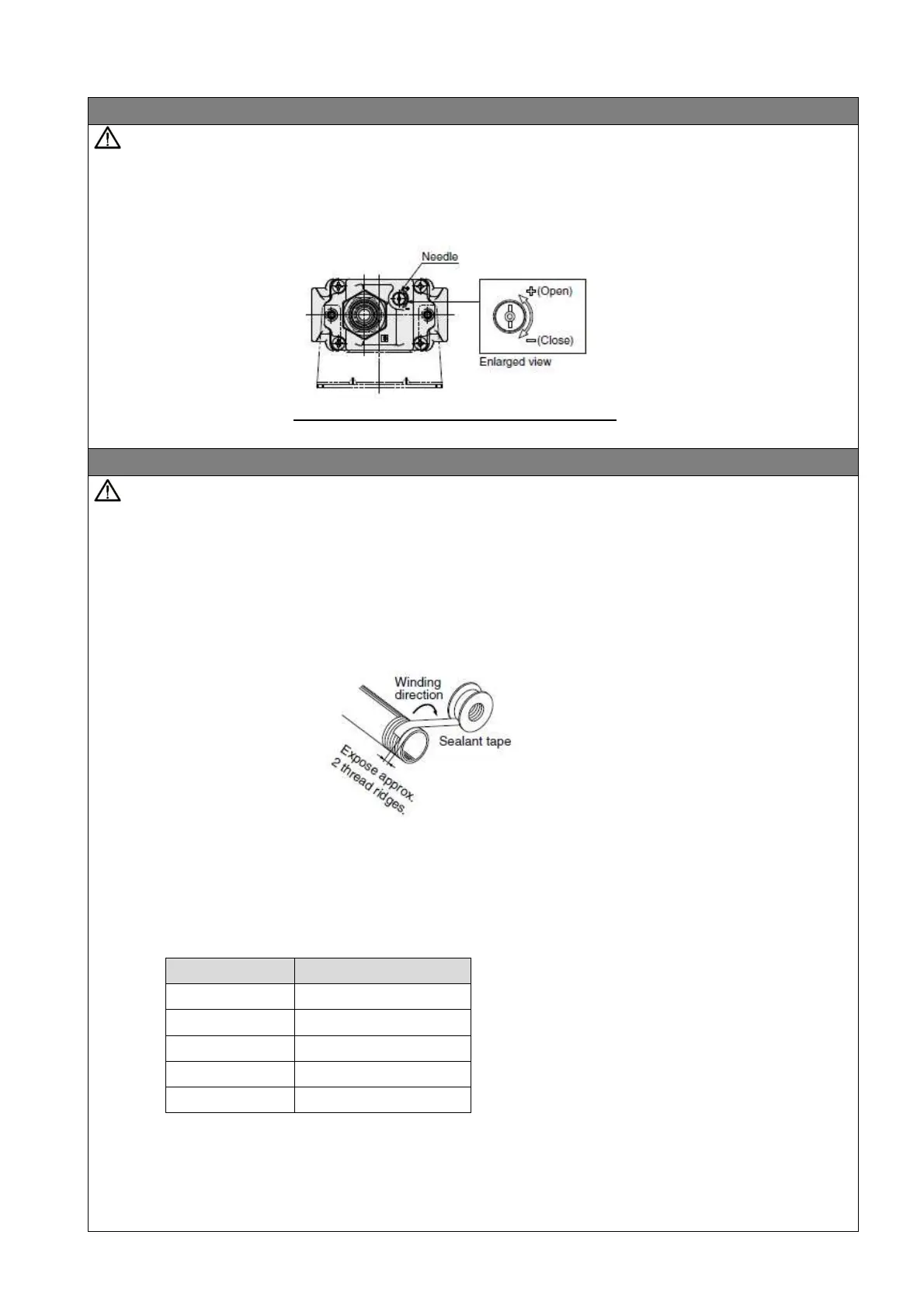

2. Winding of sealant tape

When screwing together pipies and fittings, etc., be certain that chips from the pipe

threads and sealing material do not get inside the product. Also, when the sealant tape is

used, leave 1.5 to 2 thread ridges exposed at the end of the threads.

3. Tighten threads with the proper tightening torque

When screwing pipes into this product, tighten with the torques giving below. Also, when

using SMC fitting, please tighten with the torque conforming to Catalog or operation

manual.

4. Piping to products

When piping to products, avoid making an error of supply port etc., by referrng to the

operation manuals.

-6-

Recommended tightening torque

Thread size

Torque [N・m]

1/4 12 to 14

3/8 22 to 24

1/2 28 to 30

3/4 28 to 30

1 36 to 38

Loading...

Loading...