Electro-Pneumatic Regulator Precautions

Be sure to read before handling.

1.

Screw piping together with the recommended

proper torque while holding the side that has

female threads.

Looseness or faulty sealing will occur if tightening torque is

insufficient, while thread damage will result if the torque is

excessive. Furthermore, if the side with the female threads is

not held while tightening, excessive force will be applied

directly to piping brackets, etc. causing damage or other

problems.

2. Do not allow twisting or bending moment to

be applied other than the weight of the

equipment itself.

Provide separate support for external piping, as damage may

otherwise occur.

3.

Since excessive moment loads and the

propagation of vibrations, etc. can easily

result from inflexible piping made of materials

such as steel, avoid these problems by using

flexible tubing for intermediate connections.

Piping Piping

Warning

1. Preparation before piping

Before piping is connected, it should be thoroughly blown out

with air (flushing) or washed to remove chips, cutting oil and

other debris from inside the pipe.

Caution

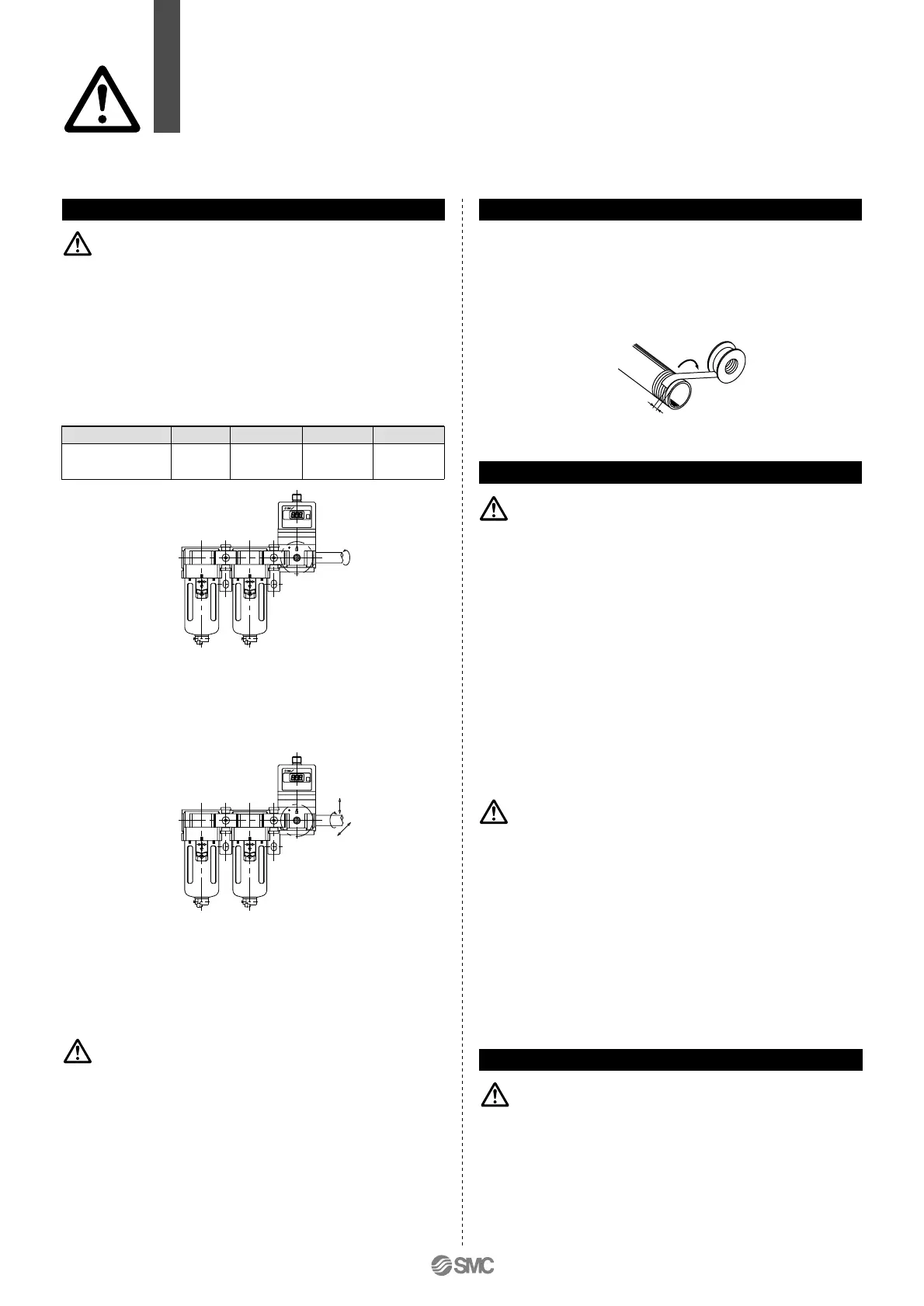

Wrapping

direction

Pipe tape

Expose approx. 2 threads

1. Do not operate in locations having an

atmosphere of corrosive gases, chemicals,

sea water, or where there will be contact with

the same.

2. Do not operate in locations where vibration

or impact occurs.

3. In locations which receive direct sunlight,

provide a protective cover, etc.

4. In locations near heat sources, block off any

radiated heat.

5. In locations where there is contact with

spatter from water, oil or solder, etc.,

implement suitable protective measures.

Warning

2. Wrapping of pipe tape

When screwing together pipes and fittings, etc., be certain that

chips from the pipe threads and sealing material do not get

inside the piping.

Also, when pipe tape is used, leave 1.5 to 2 thread ridges

exposed at the end of the threads.

Operating EnvironmentOperating Environment

In locations where the body is exposed to

water, steam, dust, etc., there is a possibility

that moisture or dust could enter the body

through the EXH (solenoid) ports, thereby

causing problems. To overcome this, simply

install tubing to each port, using the fittings,

and extend the tubing so that the other end is

at a location where no water splash, etc.

occurs. Make sure not to bend, or block the

I.D. of the tubing as this will have a detrimental

affect on the pressure control.

Caution

1. These products are designed for use with

compressed air. Contact SMC if any other

fluid will be used.

2. Do not use compressed air which includes

chemicals, synthetic oils containing organic

solvents, salt, or corrosive gases, etc., as

this can cause damage or malfunction.

Air Supply

Warning

Series ITV1000/2000/3000

Recommended proper torque: N

.

m (kgf

.

cm)

Connection thread

Torque

1/8

1/4 3/8 1/2

7 to 9

(70 to 90)

12 to 14

(120 to 140)

22 to 24

(220 to 240)

28 to 30

(280 to 300)

16

REGULATOR

ITV2000

REGULATOR

ITV2000

Loading...

Loading...