105

10 - CLEANING AND MAINTENANCE

10.1 General warnings and precautions

Cleaning and maintenance operations must be entrusted to expert personnel who know the

machine (mechanical maintenance technician and electrical maintenance technician, each

according to his own field of skills).

For maintenance operations it is mandatory:

• to keep the area surrounding the machine clean and dry. Always eliminate oil stains.

• follow the maintenance in progress status procedure described in paragraph 10.2.

• make sure that the machine has been disconnected from the power line before working on

electrical components.

• only use original spare parts.

• when the operations are complete, put the machine back in its initial conditions by

remounting any guards that have been removed and closing the electric panel with the key.

The key of the electric panel must be stored by the electrical maintenance engineer in a

safe place, preventing access to unauthorised people.

It is forbidden:

• to repair the machine while it is running or powered.

• to use matches, torches or open flames for lighting.

• for unauthorised people to access the machine.

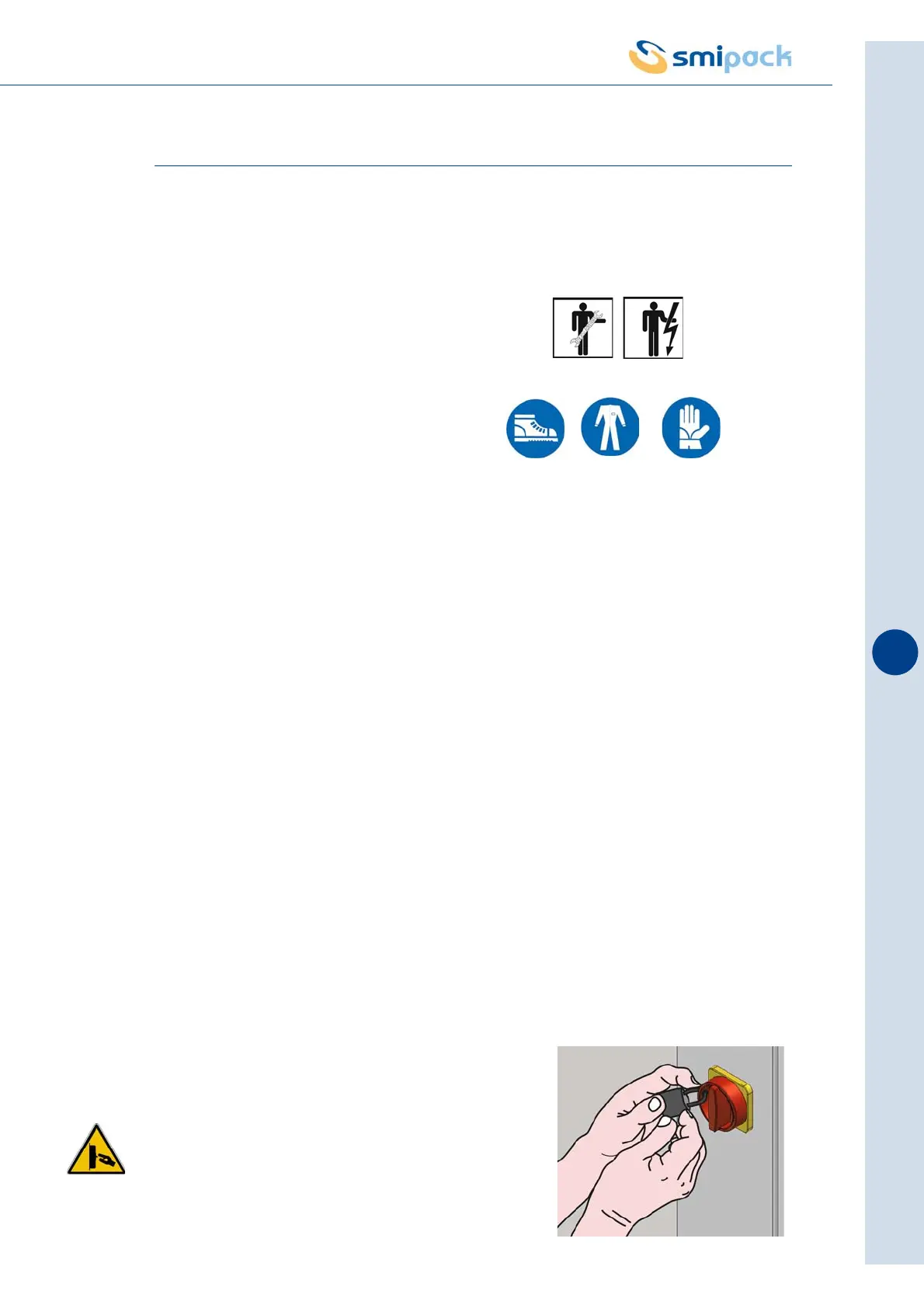

10.2 Placing in maintenance status procedure

Before starting any maintenance and control

operation it is necessary to let the machine run until

all of the products inside it are emptied out.

Switch the machine off and unplug it from the mains.

If the machine has a pneumatic disconnector (used

when the machine is configured with optional

pneumatic systems), the air has to be discharged

from the system before switching it off and

unplugging it from the mains.

All the operations indicated in this chapter

must be carried out by qualified personnel

and with adequate personal protective

equipment for the operations being

performed. For more information see the

paragraph 4.8 and 7.10.

Loading...

Loading...