Chapter 7 – Prestart Inspection

TB60 – 0083739 33

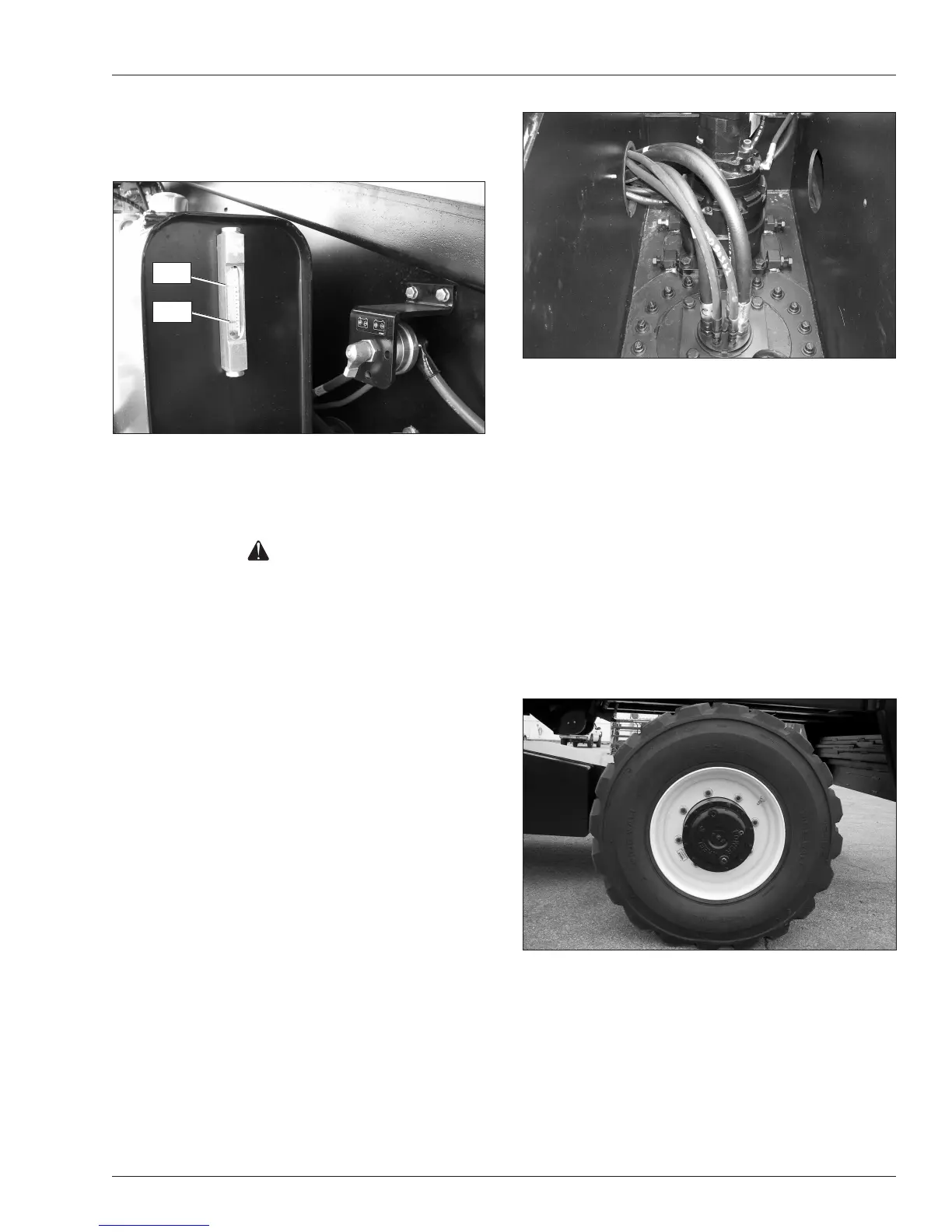

2. Open the door on the right side of the chassis to ac-

cess the hydraulic uid level gauge (refer to Figure

7.8).

Figure 7.8 – Hydraulic Fluid Gauge

3. Make sure the uid level is between the minimum

and maximum lines.

Caution

Not all hydraulic uid is suitable to use in the hy-

draulic system. Some have poor lubricating char-

acteristics and may increase component wear. Only

use hydraulic uid as recommended.

4. If necessary, remove the ller cap and add uid of

the proper type. Replace the cap making sure it is

tightly in place.

Note

Refer to Chapter 2 for the proper type and grade of

hydraulic uid to use. The need to regularly add uid

indicates a leak that should be corrected.

5. The sight glass on the reservoir has an internal

thermometer to measure the uid temperature. The

temperature should be less than 200°F (93°C).

Fluid Filter

Checking the condition of the hydraulic uid lter is part

of the machine maintenance schedule and should not

be performed by the operator.

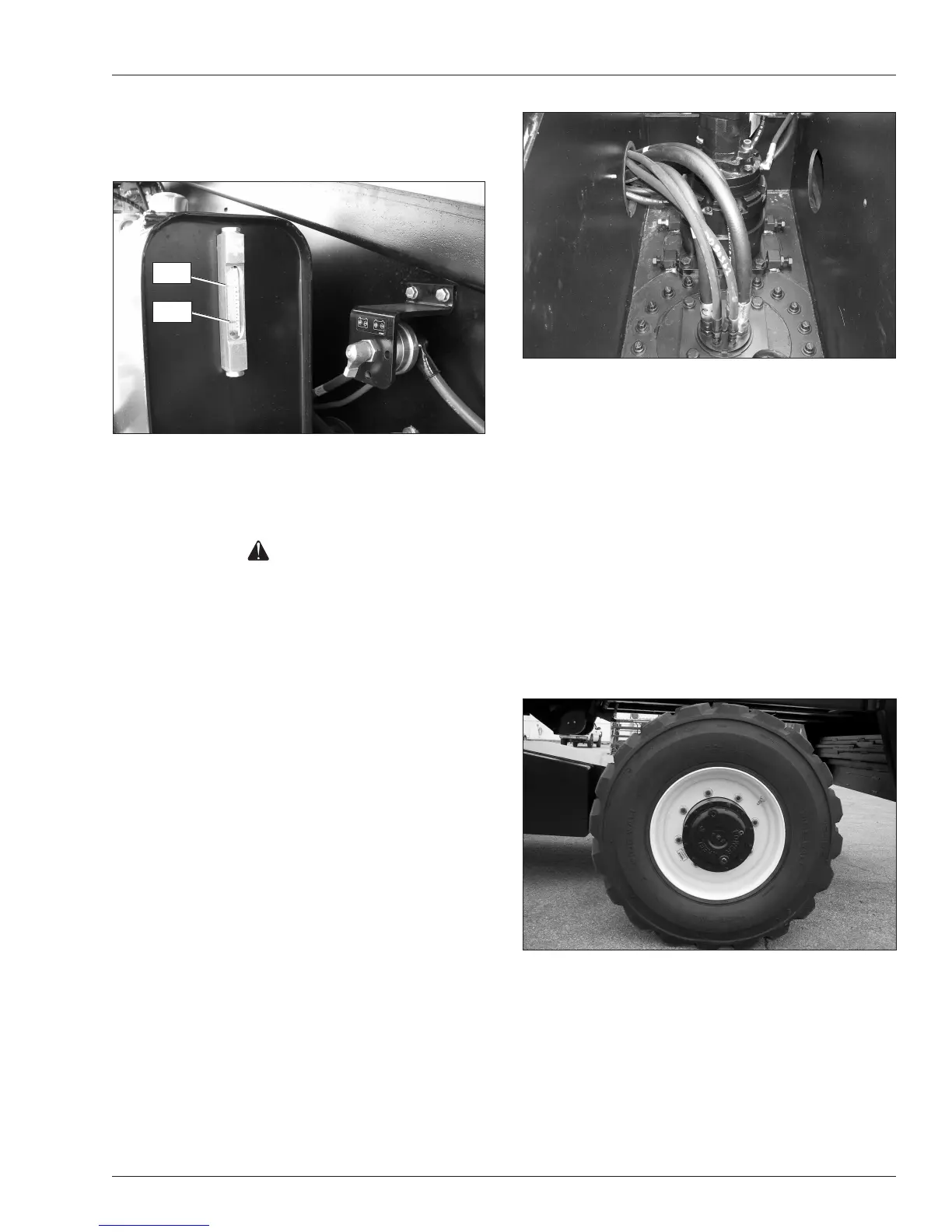

Hoses, Tubes, and Fittings

To inspect the hoses, tubes and ttings:

1. Inspect all hydraulic hoses, tubes, and ttings for

wear, leakage, or damage (refer to Figure 7.9).

Figure 7.9 – Hoses, Tubes, and Fittings

2. Make sure the hoses are properly routed to avoid

sharp edges, kinking, and scufng.

3. Inspect the tubes for dents or other damage that

may restrict uid ow.

4. Make sure all hoses and tubes are held rmly in

their support brackets.

5. Check under the chassis for uid that has leaked.

Hydraulic fluid leaks are easily visible on the

ground.

Tires and Wheels

Visually inspect the tires and wheels (refer to Figure

7.10) to make sure they are suitable for service.

Figure 7.10 – Tires and Wheels

Foam lled tires do not have a pressure decal or a

valve core.

To inspect foam lled tires and wheels:

1. Check the wheel lug nuts to see that none are miss-

ing, damaged, or loose.

Full

Add

Loading...

Loading...