Preparing the equipment for use

ENGLISH 11

6.2 Assembly - vacuum operation – only

model 441 (with model 440 as

accessory)

Fit the following parts for the vacuum operation:

Exhaust air elbow (20) to be fitted to the standard

machine.

Catcher (21) to be fitted to the exhaust air elbow.

Vacuum pipe (19) to be fitted to the standard

machine.

[Note: When preparing model 440 with vacuum

operation accessory kit 49 00 546 for the first time,

also fit the anti-static wire in accordance with the

details supplied with the accessory kit. For model

441, the anti-static wire is already fitted as standard.]

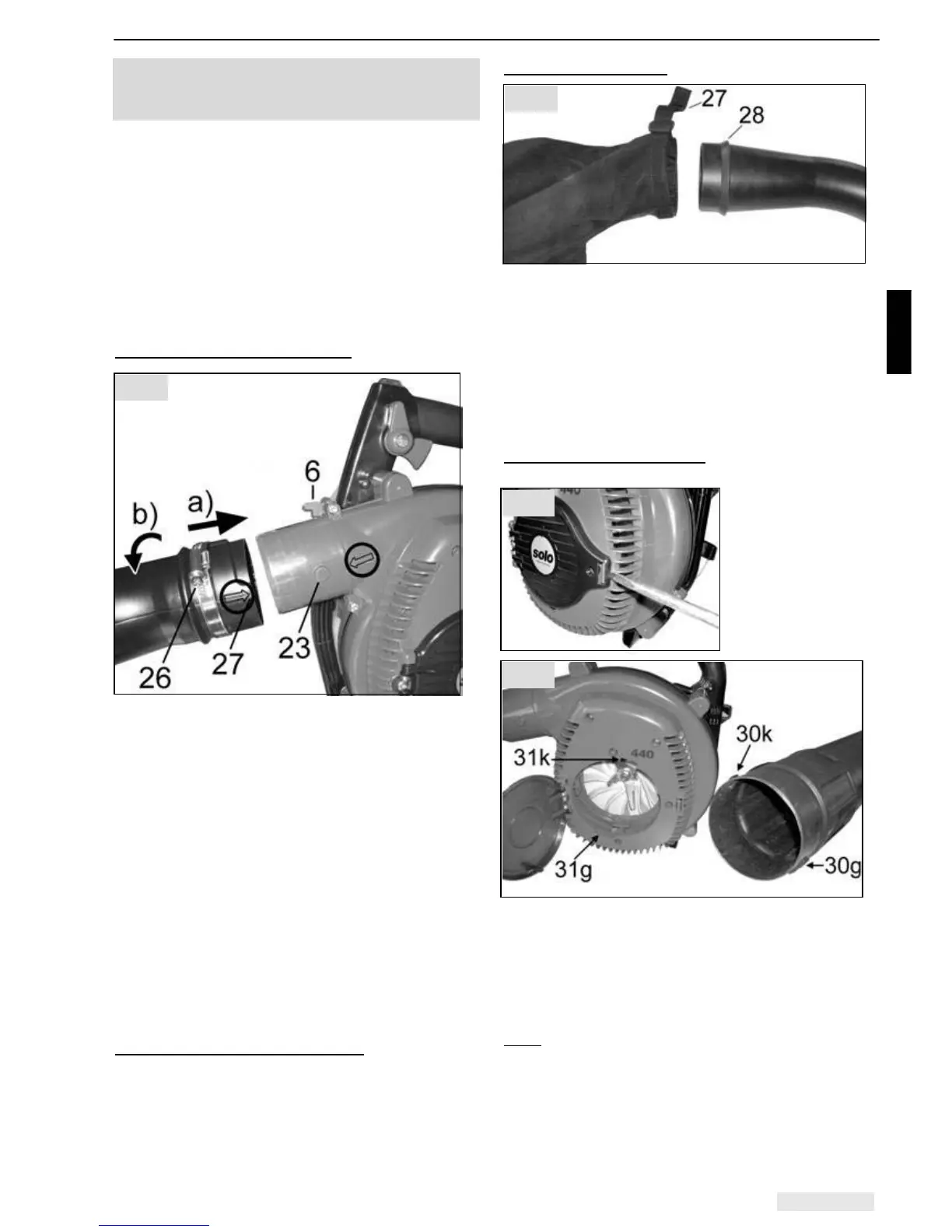

Exhaust air elbow assembly (20)

Tip: To make the assembly easier, the standard

machine can be positioned on a level surface, air

filter side down. For this, ensure that the tank cap is

tightly secured to prevent fuel spillage.

• Undo clip (26) on exhaust air elbow (20).

a) Push exhaust air elbow (20) with groove (27) over

cam (23) of the standard machine.

The arrows on the exhaust air elbow and the

standard machine must be aligned accurately,

when the parts are pushed together (the wide

groove (27) over the large cam (23), and the

narrow groove over the smaller cam).

b) Rotate the exhaust air elbow through 45º over the

stand until the lock (6) engages behind the groove

on the exhaust air elbow; do not tighten

excessively!

• Secure clip (26).

Dismantling the exhaust air elbow

• Undo clip (26).

• Gently lift up the lock (6) and rotate the exhaust

air elbow back at the same time until the arrows

are exactly lined up again.

• Pull the exhaust air elbow from the standard

equipment.

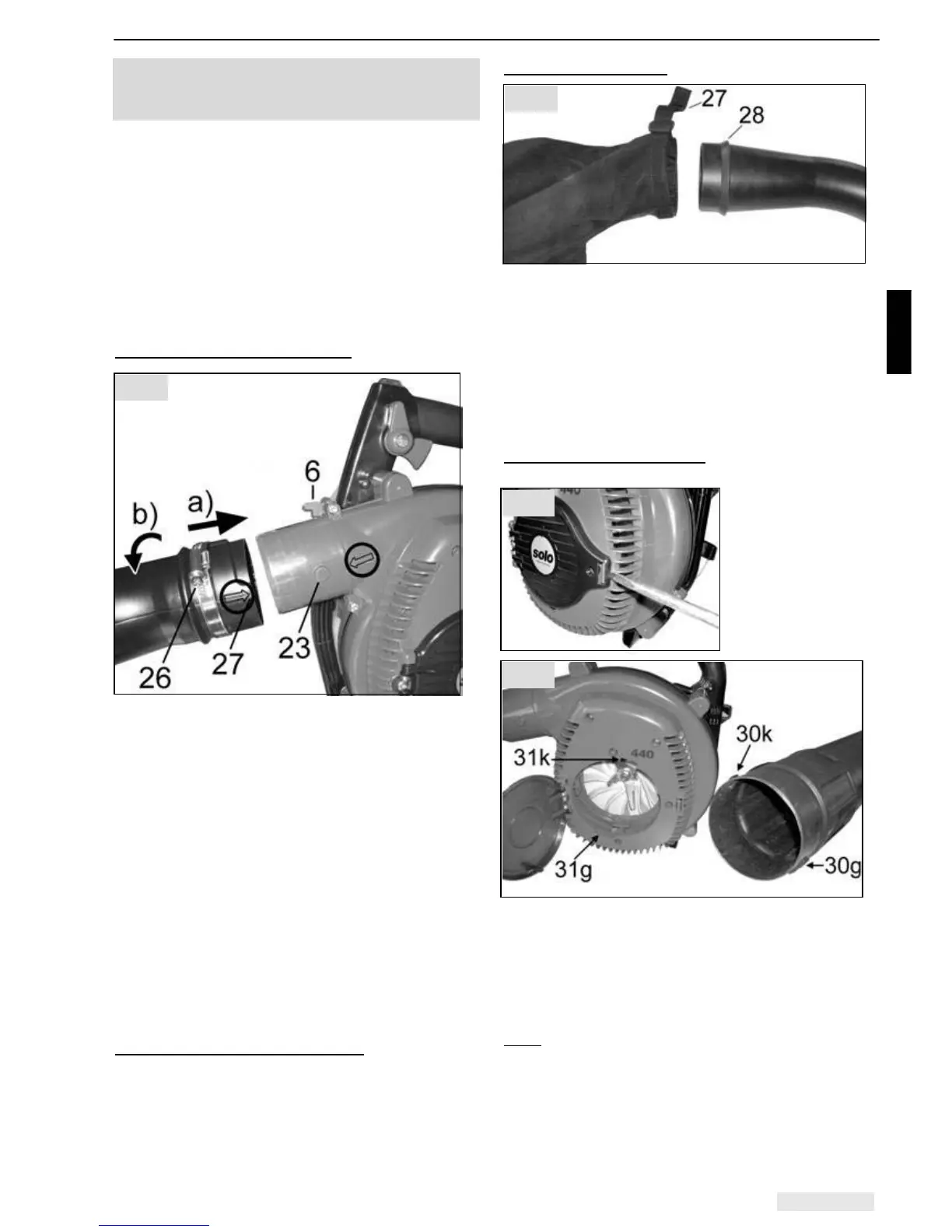

Catcher assembly (21)

• Open Velcro strap (27) on catcher.

• Push the catcher so far over the elbow, that the

entire width of the Velcro strip is located behind

the bead (28) on the reducing part of the elbow.

• Tighten and close the Velcro strip.

• Secure the shoulder strap to the catcher eyes.

To dismantle the catcher, open the Velcro strip and

remove the catcher from the exhaust air elbow.

Vacuum pipe assembly (19)

With a screwdriver,

push into the side

opening of the fan

cover to release it.

Open the fan cover wide. Push vacuum pipe cams

(30) into grooves (31) on the inner ring of the fan

casing. Ensure that the large cam (30g) is located in

the wide groove (31g) and the small cam (30k) in the

narrow groove (31k).

Rotate the vacuum pipe clockwise until it is clearly felt

to engage.

Note:

To enable the power tool which has been

attached for vacuum operation to be stored on stand

(14) again Î

first loosen the clip (26) and lift up the lock (6), then

rotate the exhaust air elbow back so that the arrows

on the exhaust air elbow and the standard unit are

exactly lined up again.

Fig. 7

Fig. 8

Fig. 6

Fig. 9

Loading...

Loading...