CLEANING

• Carefullycleansprayeraftereveryuse.

• Pourorsprayallremainingchemicaloutofsprayer.

• Pourasmallamountofwaterforwatersolublechemicals,ormineral

spiritsforoil-basedchemicals,intothetank.

• Pressuriseandspraythroughsystemuntilallliquidisgone.

• Repeatprocesswithwarmsoapywater.

• Repeatprocesswithwarmclearwater.

• Useanabsorbentclothtodryallinternalsurfaces.

• Followtherecommendationsofthechemicalmanufacturerfor

disposing of waste water and chemicals.

• Donotuseaggressiveorabrasivecleaningagents.

MAINTENANCE:

• Priortostorage,empty,cleananddrysprayer.

• Alwaysstorethesprayerinadryarea,protectedfromfreezing,heat

and sunlight.

• LubricateO-ringinpressurereliefvalvewithnon-watersoluble

grease* on a regular basis.

Disassembly:Unscrewpressurereliefvalvefromtankandpullthe

valve body out of the screw cap. Clean, lubricate, and replace.

• Pump Maintenance: Pump pressure sealing is accomplished with an

O-ring(5)onthepumppiston(4)whichmoveswithinthecylinder(3).

Periodically this O-ring should be greased with a non-water soluble

grease*. If worn, it should be replaced. A small umbrella valve at the

bottom of the cylinder prevents the formula from entering the cylinder.

Keep these parts clean and replace if worn.

Disassembly:Unscrewpumpassemblyfromtank.Carefullyremove

umbrellavalve(6)fromthebottomofcylinder(3).Whileholding

cylinderrmlywithonehandandthehandleofthepumppiston(4)

rmlyintheother,withthepistonfullyinsertedinthecylinder,pull

backonthepistonquicklyandforcefully.Tore-assemble,placethe

pistonassemblybackintocylinder,placeheelofhandsonopposite

sidesofthetankcap,whilekeepingcylinderinplacewithngers,tap

bottomofcylinderagainstaatpaddedsurface.Assemblywilllock

into place.

• Tank Cap: Asmallamountofnon-watersolublegrease*ontankcap

threadsandbothsidesofthegasketeasestighteningandloosening.

• Regular Inspection: Inspect and replace worn or damaged parts

promptly.Payparticularattentiontotankcapgasket,pressurerelief

valveandseal,inationvalve(iftted),umbrellavalveO-ringsand

seals throughout sprayer. Regular lubrication of O-rings and seals is

recommended.

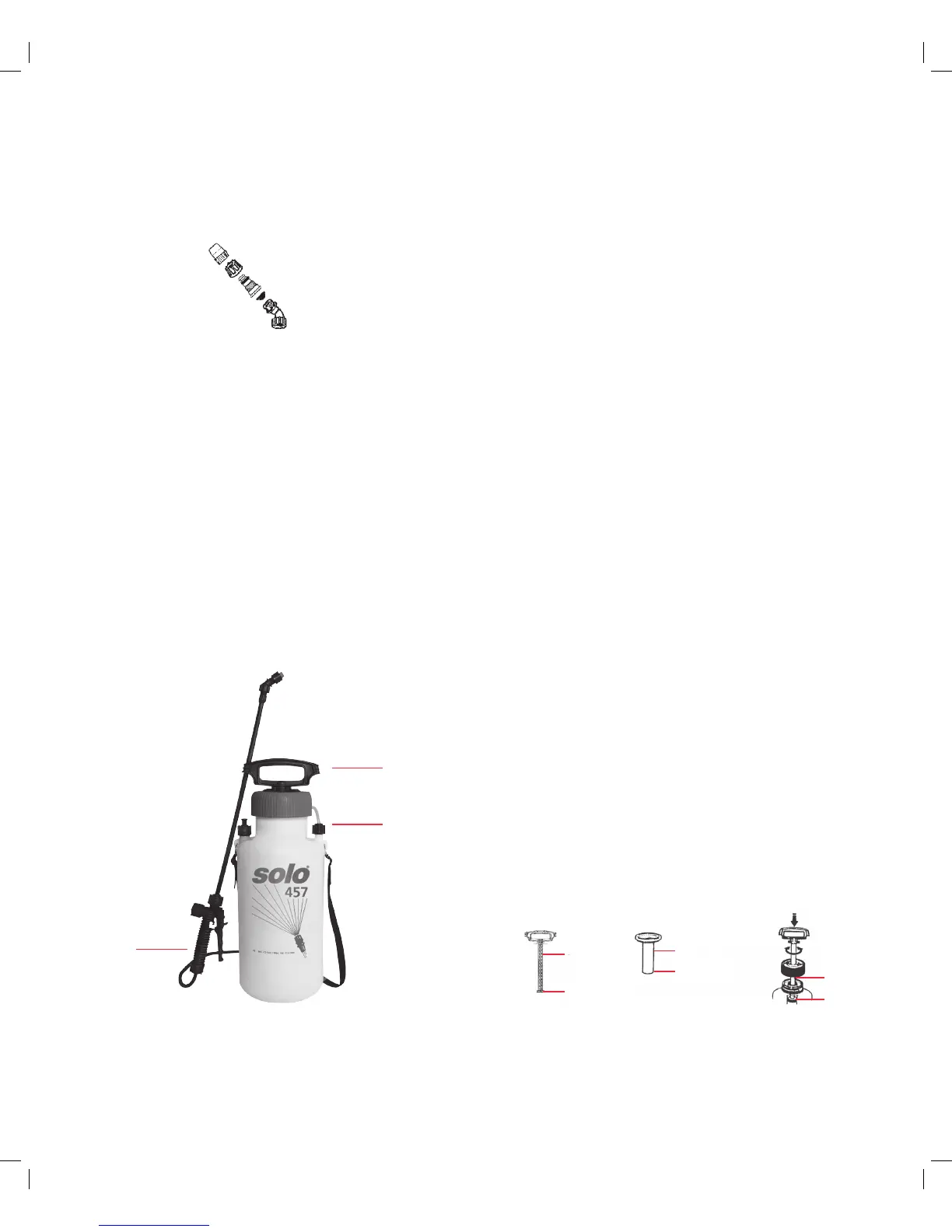

REMOVING THE NOZZLE

Unscrewthenozzlecap(1)fromthenozzlebody(3).Thisisbest

accomplishedwhiletheretainingnut(2)isfastenedtightlytotheelbow

(5).Next,unscrewtheretainingnut(2).Pushthenozzlebody(3)out

oftheretainingnut(2).Thelterwithgasket(4)willcomeoutwiththe

body.Toreinstallthenozzle,reversethe

above instructions.

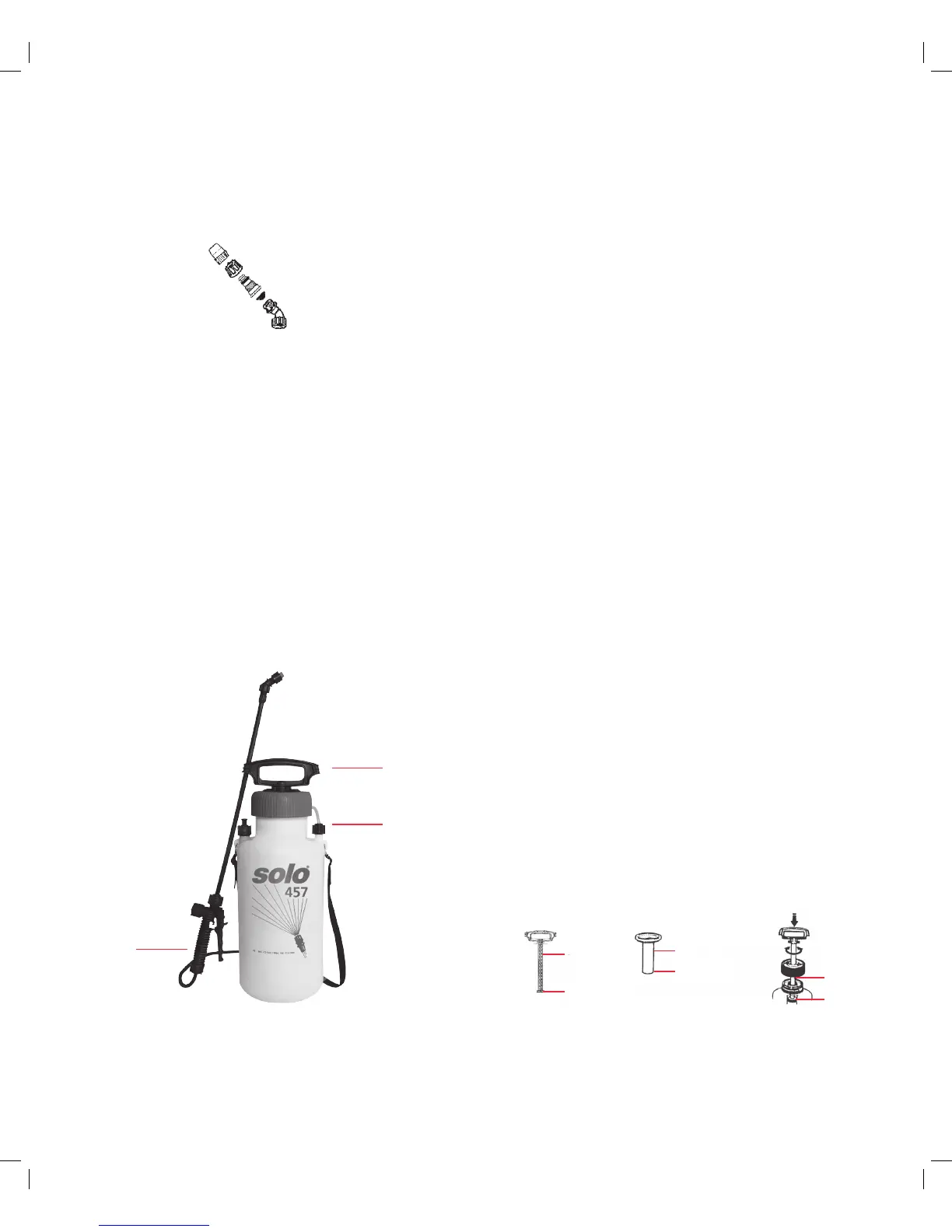

OPERATION

• Beforeusingsprayerwithchemicals,llsprayerwithfreshwaterto

assure that you have it properly assembled; pressurise and then

practice spraying. When thoroughly familiar with sprayer operation,

follow normal operating procedures.

• Turnpumphandlecounterclockwisetoremovepump.

• Filltankwithpremixedformulauptodesiredlevel.(Do not exceed

maximum fill mark.)Observerecommendationsofchemical

manufacturer.

• Tightencapandpumpassemblyforagoodseal.

• Pumptoamaximum45psior3barpressure.Thevalvestemonthe

pressurereliefvalvewillriseuptoventexcesspressureover45psi.

• Startorstopsprayingbysqueezingorreleasingtheleveronthe

shut-offvalve(3).Thespraypressurecanbemonitoredwithan

optional pressure gauge.

• Priortoeveryremovalofpump(1),releasepressurerstbypulling

uponthepressurereliefvalvestem(2).

1. Nozzle

2. Retaining Nut

3. Nozzlebody

4. FilterwithGasket

5. Elbow

1

2

3

*Petroleumjellyworkswell.

4

5

3

4

5

6

2

Loading...

Loading...