Commissioning

General information

• DIP switches set to "OFF" position on delivery.

• Do not apply external voltage to the connections of the control system,

otherwise the control system is immediately destroyed.

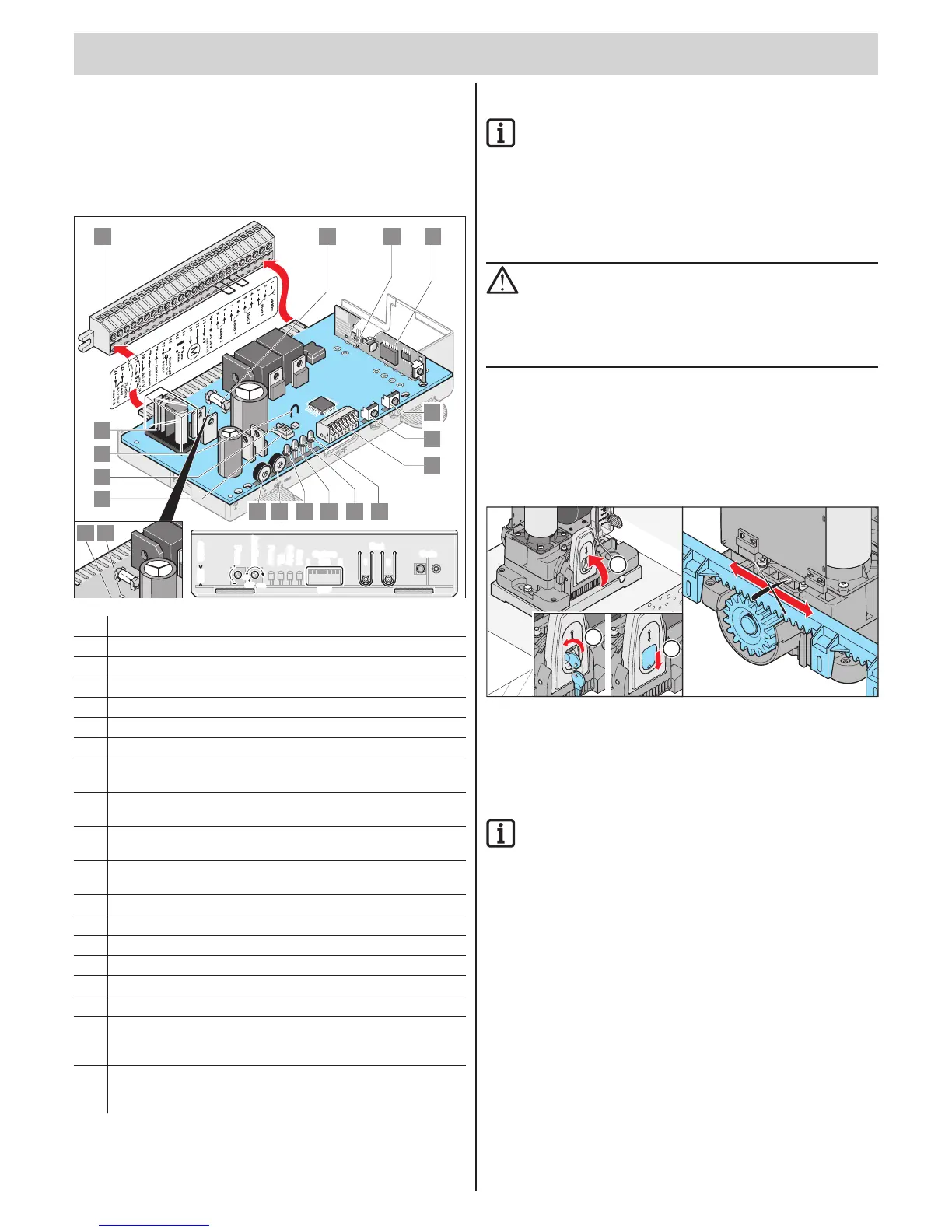

Overview of the control system

24

23

22

21

20

19 18

17

16

15 14

13

12

10

9

8

7

6

5 4

3

2

1

11

LE

D

1 L E D

2

LE

D

3 LE

D

4

T

1

P

2

T2

1

2

5

6

7

14

15

16

17

43

19 18

9810111213

Start

Code

1

1 8ON

OFF

OFF

max.

ON

Options

41035

Force

TimeAuto

Safety

Start

Power

WL

ABS

2

Start

Code

1

18ON

OFF

OFF

max.

ON

Options

41035

Force

TimeAuto

Safety

Start

Power

WL

ABS

2

1. Direct connector, 24-pole

2. Fuse for warning light-1 connection, terminal 16 + 17

3. Connection of the external antenna

4. Radio receiver

5. Button 2 (T2*)

6. Button 1 (T1*)

7. DIP switch 1 - 8

8. Start (LED 4*)

Lights when a radio command is sent or a button is pressed.

9. Safety (LED 3*)

Lights when a safety input is actuated.

10. WL (LED 2*)

Flashes when the operator opens or closes the gate.

11. Power (LED 1*)

Lights when mains power is on.

12. Potentiometer (P2*) for setting time of automatic closing

13. Potentiometer (P1*) for adjusting the power tolerance.

14. Connection of TorMinal

15. Protection against incorrect insertion for the connection of TorMinal

16. Wire jumper, disconnecting switches off soft running.

17. Relay contact, Terminals 23 + 24

18. LED:

Operator left: end position gate CLOSED

Operator right: Door end position OPEN

19. LED:

Operator left: Door end position OPEN

Operator right: Door end position CLOSED

* See the controller pcb for this label.

Safety instructions

IMPORTANT INFORMATION!

After installation of the operator the person responsible for

installation of the drive must issue an EC Declaration of

Conformity for the gate system in accordance with Machinery

Directive 2006/42/EC and attach the CE symbol and a type

plate. This is also required for private installations and also

if the operator is retrofitted to a manually operated gate.

This documentation and the Installation and Operating

Instructions are retained by the operator.

ATTENTION!

The adjustment of the force tolerance is safety-relevant and

must be performed by qualified personnel with the utmost care.

If the adjustment of the spring unit is excessively high,

people or animals could be injured and objects damaged.

Select a force tolerance that is as low as possible so that

obstacles are detected quickly and safely.

Programming the operator

The control unit has an automatic force setting. The control system

memorizes the required force during the "OPEN" and "CLOSE" gate

movements and stores it when the end position has been reached.

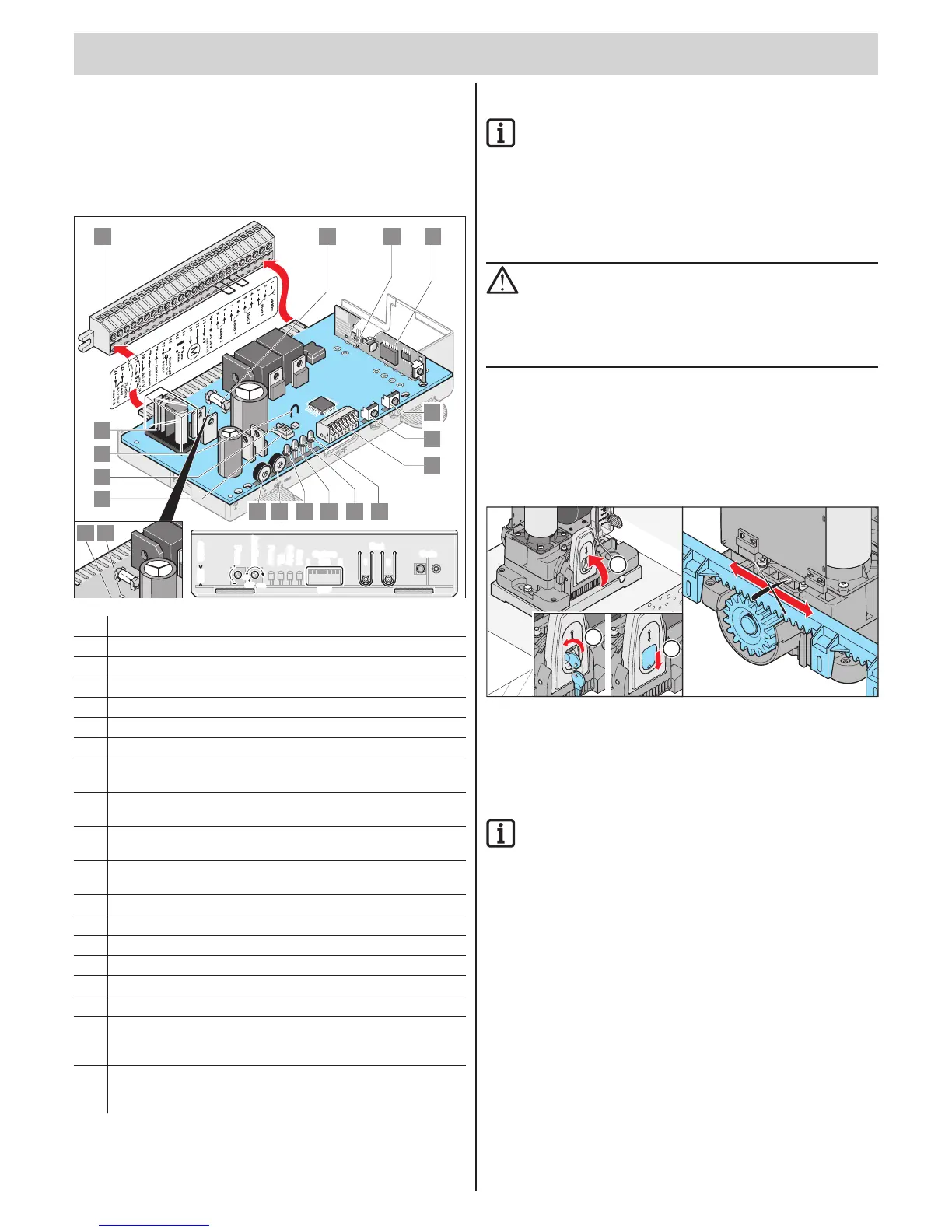

Locking the operator

1

2

3

1. Traverse operator to centre position.

2. Lift lever (1) up and lock with key until the motor locks - loud click.

Release lever (1).

3. Remove key and push dust cap down.

IMPORTANT INFORMATION!

Move gate back and forth by hand so the pinion meshes with

the rack more easily and the motor can lock.

⇒ Operator is locked and the gate can only be moved with the motor

4. Plug in controller.

5. Switch on main switch.

⇒ LED (power) on

Loading...

Loading...