Maintenance and care

29

Maintenance and care

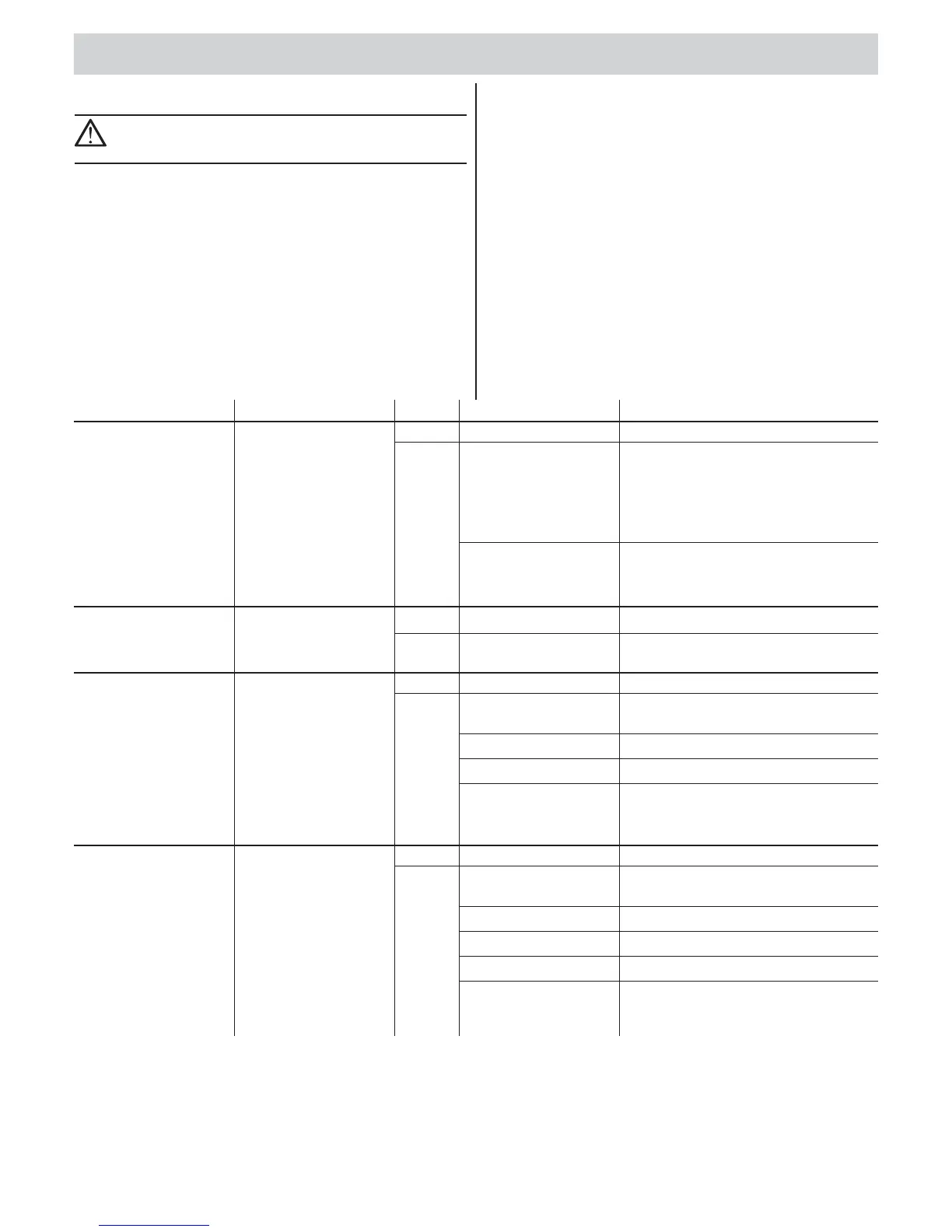

Testing Behaviour Yes/No Possible cause Remedy

Power deactivation

Stop the gate leaf by hand

while it is closing.

Do not clutch the gate leaf.

Does the gate stop and

reverse when lightly held?

Yes No action necessary.

No Force tolerance too high. Reducing force tolerance:

• Open and close the gate completely twice

under supervision.

• Rotate the “Gate 1” or “Gate 2”

potentiometer completely to the left until

the test is successful.

Control unit defective. • Decommission the gate and lock

it to prevent reactivation.

• Call customer service!

Emergency release

Procedure as described

under “Locking and

unlocking operator”.

Can the gate be opened and

closed easily by hand?

Can the operator

be unlocked?

Yes No action necessary.

No Hinges rusted. Lubricate gate hinges.

Safety contact strip,

if present

Open/close the gate and

actuate the strip.

Does the gate behave as set

with DIP switch 1, 2 or 3?

Yes No action necessary.

No Cable broken. • Check wiring.

• Replace broken cables.

Terminal loose. Tighten terminal.

DIP switch adjusted. Set the DIP switch.

Safety contact strip

defective.

Safety contact strip

evaluation unit defective.

• Decommission the gate and lock

it to prevent reactivation.

• Call customer service!

Photo eye, if present

Open/close the gate and

interrupt photo eye.

Does the gate behave as set

with DIP switch 1, 2 or 3?

“Safety” LED on?

Yes No action necessary.

No Cable broken. • Check wiring.

• Replace broken cables.

Terminal loose. Tighten terminals.

DIP switch adjusted. Set the DIP switch.

Photo eye soiled. Clean the photo eye.

Photo eye fault. • Decommission the gate and lock

it to prevent reactivation.

• Call customer service!

Safety instructions

DANGER!

Never use a water hose or high-pressure cleaner to spray

down the operator or the control unit housing.

Do not use acids or alkalis for cleaning.

Keep operator clean and clean the push rod with a dry cloth

when needed.

Check the control unit housing regularly for insect infestation

and clean if necessary.

Check the control unit housing regularly for moisture and

dry if necessary.

Check that all screws and bolts of the fi ttings are tightened.

Retighten loose fi xing bolts.

Check that the connection control unit housing cover is free of leaks.

Regular testing

Check the function of the safety devices at least every 6 months.

See EN 12453:2000.

Check the function of the pressure-sensitive safety devices at least

every 4 weeks. Example: Safety contact strip with separate evaluation

unit. See EN 60335-2-95:11-2005.

Loading...

Loading...