0739P300 Instruction Montage Supercal 739 DE-EN-FR-IT 10-10-2013

Installation guide Supercal 739

The compact mechanical single or multiple jet thermal energy meter

cal 739

is a precision measuring instrument approved for individual

of heating systems and must be handled with care.

The Supercal 739 is available in a heating or cooling version and determines

the thermal or cold energy exchanged by a heat-

exchanger circuit.

The Supercal 739 complies wi

th the requirements of the European

Directive MID 2004/22/EC modules B and D and of the standard EN

1434 class 3.

Important

The energy meter may only be used under the conditions indicated on the

manufacturer’s rating plate! The seals must not be removed o

removed only by authorised persons.

If these conditions are disregarded, the factory warranty and the calibration

will no longer be the manufacturer’s responsibility.

Do not shorten the cable between the flow meter and the integrator and the

cab

les for the temperature sensors or modify them in any way whatsoever.

Before installation

Check the installation data and compare them with the specific characteri

tics of the thermal energy meter.

Installation

The prescriptions related in the standard EN1434-

the Supercal 739 is installed.

Depending on its particular version and use (heat and/or cooling m

ter), the energy meter must be fitted on the “cold” or “hot” pipe side of

the installation in compliance with the indications sh

display, 1

st

position of the service menu “hot pipe” / “cold pipe”.

Place the flow meter correctly according to the direction of the fluid (an

arrow can be seen on the flow meter).

The energy meter must be fitted between two shutoff valves.

must be installed ahead of any monitoring valves so as to avoid any pote

tially interfering influence.

In any particular installation, mixed mounting positions (horizontal and vert

cal) must be avoided.

Final commissioning must be performed and documented.

All other information can be obtained from the enclosed Installation

guide Supercal 739:

http://www.sontex.ch/supercal739_e.html

The QR code located on the label of the carton

or on the integrator allows to access to the

installation guide.

Wall-mounting of the integrator

The integrator can be separated from the flow meter and fixed

using the wa

ll fixture supplied with the energy meter. If possible, install the

wall fixing component above the flow meter.

Mounting the temperature sensors

The temperature sensor cables are provided with a coloured indicator plate:

Red for mounting in the pipe on the “hot” side.

Blue for mounting in the pipe on the “cold” side.

The temperatures of use shown on the label must be respected.

A temperature sensor may be fitted directly in the flow meter. The temper

ture sensors will preferably b

e fitted directly, in other words one temperature

sensor will be fitted in the flow meter while the other sensor will be installed

on the other side of the heat exchanging circuit.

Asymmetrical mounting is also possible. In that case, a temperature sensor

will be fitted directly in the flow meter of the energy meter while the other

temperature sensor will be fitted on the other side of the heat exchanging

circuit in a sensor pocket defined according to the table set out below. To

guarantee accuracy in this

type of use, the following conditions must be

respected: minimum temperature ∆T

min

≥ 6 K when the minimum flow is less

than ≤ 100 l/h.

Make sure that the sensors are mounted until they stall with the bottom of

the sensor pocket.

Ø 5x31 mm M10x1

Ø 5x 31 mm G3/8"

Ø 5x 31 mm G1/2"

Ø 5.2x 31 mm M10x1

Ø 5.2x 31 mm G3/8"

2

Installation guide Supercal 739

The compact mechanical single or multiple jet thermal energy meter

Super-

is a precision measuring instrument approved for individual

metering

The Supercal 739 is available in a heating or cooling version and determines

th the requirements of the European

Directive MID 2004/22/EC modules B and D and of the standard EN

The energy meter may only be used under the conditions indicated on the

manufacturer’s rating plate! The seals must not be removed o

r may be

If these conditions are disregarded, the factory warranty and the calibration

Do not shorten the cable between the flow meter and the integrator and the

les for the temperature sensors or modify them in any way whatsoever.

Check the installation data and compare them with the specific characteri

s-

Depending on its particular version and use (heat and/or cooling m

e-

ter), the energy meter must be fitted on the “cold” or “hot” pipe side of

the installation in compliance with the indications sh

owed on the LCD

position of the service menu “hot pipe” / “cold pipe”.

Place the flow meter correctly according to the direction of the fluid (an

The energy meter must be fitted between two shutoff valves.

The flow meter

must be installed ahead of any monitoring valves so as to avoid any pote

n-

In any particular installation, mixed mounting positions (horizontal and vert

i-

Final commissioning must be performed and documented.

All other information can be obtained from the enclosed Installation

The QR code located on the label of the carton

or on the integrator allows to access to the

The integrator can be separated from the flow meter and fixed

against a wall

ll fixture supplied with the energy meter. If possible, install the

The temperature sensor cables are provided with a coloured indicator plate:

The temperatures of use shown on the label must be respected.

A temperature sensor may be fitted directly in the flow meter. The temper

a-

e fitted directly, in other words one temperature

sensor will be fitted in the flow meter while the other sensor will be installed

Asymmetrical mounting is also possible. In that case, a temperature sensor

will be fitted directly in the flow meter of the energy meter while the other

temperature sensor will be fitted on the other side of the heat exchanging

circuit in a sensor pocket defined according to the table set out below. To

type of use, the following conditions must be

6 K when the minimum flow is less

Make sure that the sensors are mounted until they stall with the bottom of

Err 1: Flow higher than 1.2 x qs or defective hydraulic sensor.

Err 2: Measured temperature outside the homologated range or temperature

sensor defective.

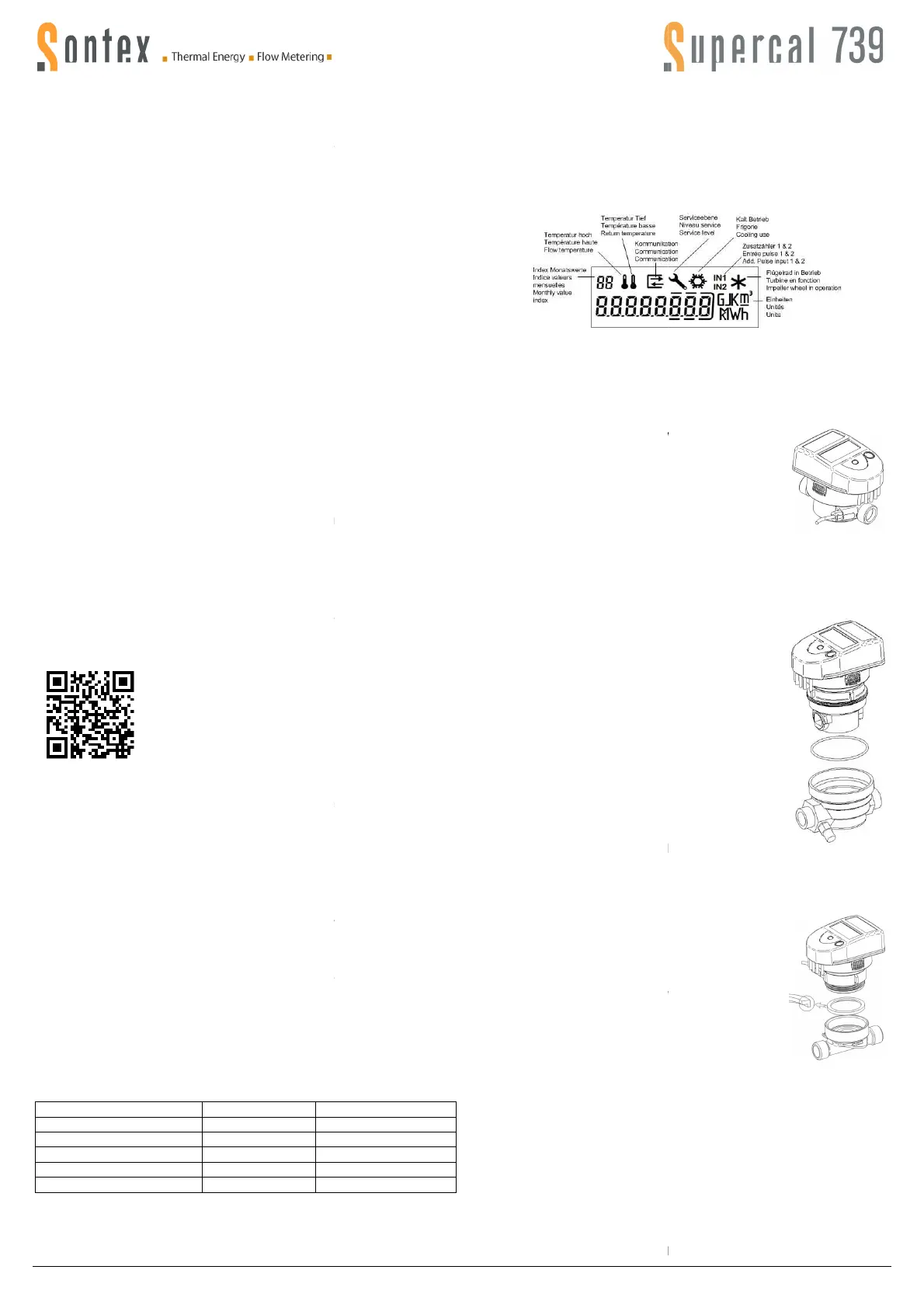

Display

The Supercal 739 LCD display has been designed to be large enough and

perfectly readable by the user.

Mounting procedure

1.

Flush out the installation pipes

2.

Close the shutoff valves before and behind the meter.

3.

Open the drainage valve to reduce the pressure and discharge the

water contained in the pipe.

4.

Consider the direction of flow circulation.

5.

Place a gasket on each side of the flow meter.

Only use appropriate new gaskets.

6.

Tighten the fixing nuts firmly by hand. Then

tighten up to the mechanical end stop using a

mounting tool.

7.

Turn the display into the desired position for

reading.

8. Check the wa

terproof of the meter placed

under pressure.

9.

Seal the flow meter and the temperature se

sors.

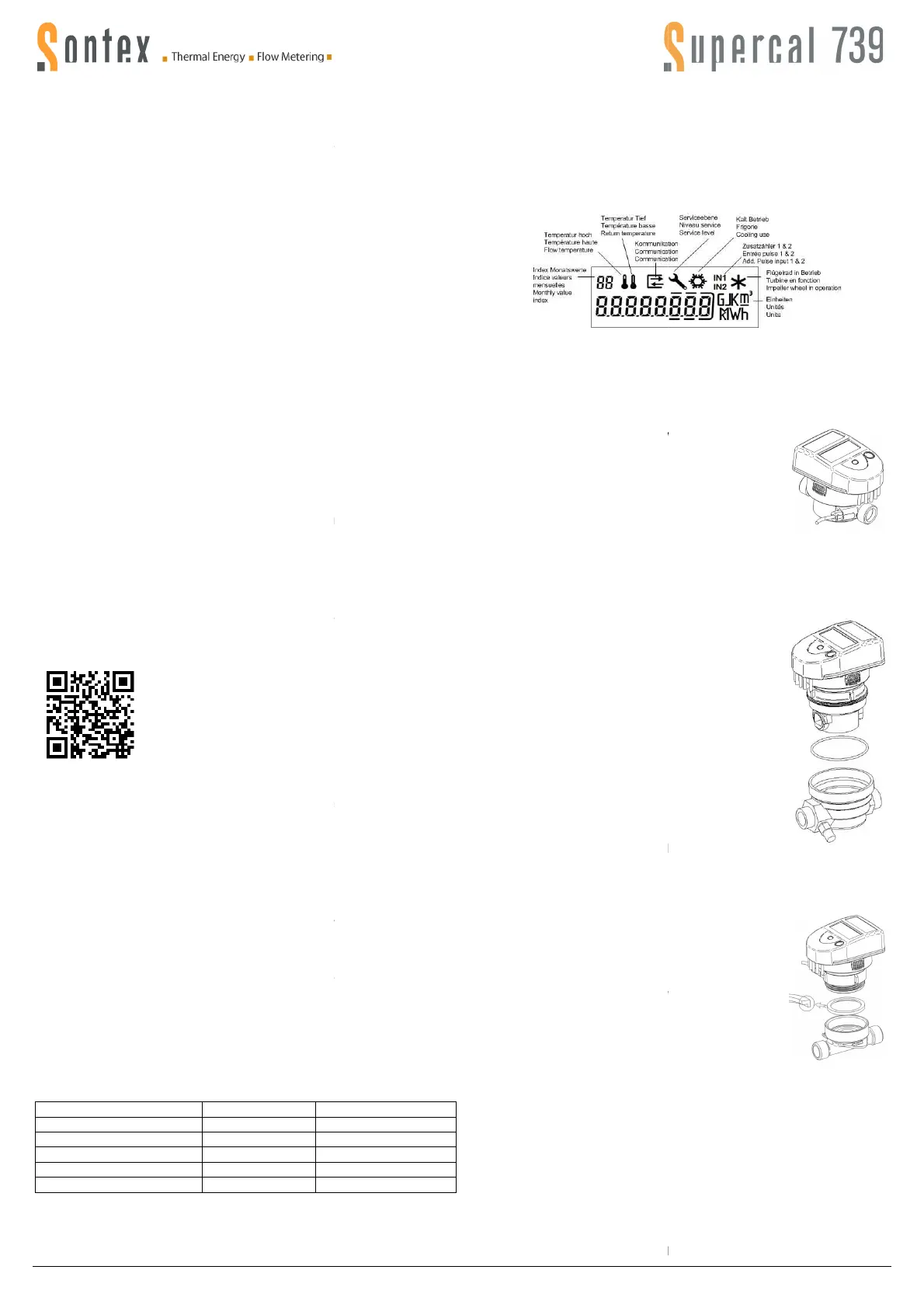

Coaxial multi jet meter with M77x1.5 connection

4.

Consider the direction of flow circulation (EAS

base).

5.

Remove the blind cover or the old meter from

the EAS

base using an installation spanner.

6. Remove the pre-

formed gasket then clean the

contact surfaces and the thread.

7. Place the new o-

ring in the EAS base. Make

sure that the o-

ring is correctly positioned

8.

Lubricate the external thread (M77x1.5’) of the

metering capsule with a fine silicone coating

9. Lay

the capsule in the base. Important! Make

sure that the blind hole in the metering capsule

is correctly positioned in the base.

10.

Screw the measuring capsule down firmly by

hand, then tighten as far as the me

end stop using a mounting tool.

11.

Turn the display into desired position for rea

ing.

12.

Seal the measuring capsule and temperature

sensors.

Coaxial multi jet meter with G2’’ connection

4.

Consider the direction of flow circulation (EAS

base).

5. Remove

the blind cover or the old meter from

the EAS base using an installation spanner.

6. Remove the pre-

formed gasket and then clean

the contact surfaces and the thread

7.

Place the new profiled gasket in the EAS base

with the plane surface facing upwards or the

gr

oove in the preformed gasket facing dow

wards. Make sure that the gasket is properly

positioned.

8.

Lubricate the external thread (G2’’) of the

measuring capsule with a fine silicone coating

9. S

crew the measuring capsule down firmly by

hand. Then tighten as fa

end stop using a mounting tool

10.

Turn the display into the desired position for

reading.

11.

Seal the measuring capsule and the temper

ture sensors.

Declaration of conformity :

The

detailed certificate of conformity can be consulted on

site: www.sontex.ch

EC-Type examination certificate

Sontex SA, 2605 Sonceboz, Schweiz, Suisse

Err 1: Flow higher than 1.2 x qs or defective hydraulic sensor.

Err 2: Measured temperature outside the homologated range or temperature

The Supercal 739 LCD display has been designed to be large enough and

Flush out the installation pipes

carefully

Close the shutoff valves before and behind the meter.

Open the drainage valve to reduce the pressure and discharge the

Consider the direction of flow circulation.

Place a gasket on each side of the flow meter.

Only use appropriate new gaskets.

Tighten the fixing nuts firmly by hand. Then

tighten up to the mechanical end stop using a

Turn the display into the desired position for

terproof of the meter placed

Seal the flow meter and the temperature se

n-

Coaxial multi jet meter with M77x1.5 connection

Consider the direction of flow circulation (EAS

Remove the blind cover or the old meter from

base using an installation spanner.

formed gasket then clean the

contact surfaces and the thread.

ring in the EAS base. Make

ring is correctly positioned

.

Lubricate the external thread (M77x1.5’) of the

metering capsule with a fine silicone coating

.

the capsule in the base. Important! Make

sure that the blind hole in the metering capsule

is correctly positioned in the base.

Screw the measuring capsule down firmly by

hand, then tighten as far as the me

chanical

end stop using a mounting tool.

Turn the display into desired position for rea

d-

Seal the measuring capsule and temperature

Coaxial multi jet meter with G2’’ connection

Consider the direction of flow circulation (EAS

the blind cover or the old meter from

the EAS base using an installation spanner.

formed gasket and then clean

the contact surfaces and the thread

.

Place the new profiled gasket in the EAS base

with the plane surface facing upwards or the

oove in the preformed gasket facing dow

n-

wards. Make sure that the gasket is properly

Lubricate the external thread (G2’’) of the

measuring capsule with a fine silicone coating

.

crew the measuring capsule down firmly by

end stop using a mounting tool

.

Turn the display into the desired position for

Seal the measuring capsule and the temper

a-

detailed certificate of conformity can be consulted on

the Sontex web-

: CH-MI004-13018

Loading...

Loading...