– 12 –

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belts capstan

2. Demagnetize the playback head with a head demagnetizer.

(Do not bring the head demagnetizer close to the erase head.)

3. The adjustments should be performed with the rated power

supply voltage (1.3 V) unless otherwise noted.

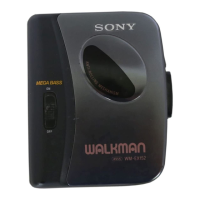

Torque Measurement

Mode Torque Meter Meter Reading

1.57 – 2.45 mN•m

FWD CQ-102C (16 – 25 g•cm)

(0.23 – 0.34 oz•inch)

FWD

0.049 – 0.147 mN•m

Back Tension

CQ-102C (0.5 – 1.5 g•cm)

(0.007 – 0.02 oz•inch)

1.57 – 2.45 mN•m

REV CQ-102RC (16 – 25 g•cm)

(0.23 – 0.34 oz•inch)

REV

0.049 – 0.147 mN•m

Back Tension

CQ-102RC (0.5 – 1.5 g•cm)

(0.007 – 0.02 oz•inch)

more than 4.90 mN•m

FF, REW CQ-201B (more than 50 g•cm)

(more than 0.7 oz•inch)

SECTION 4

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

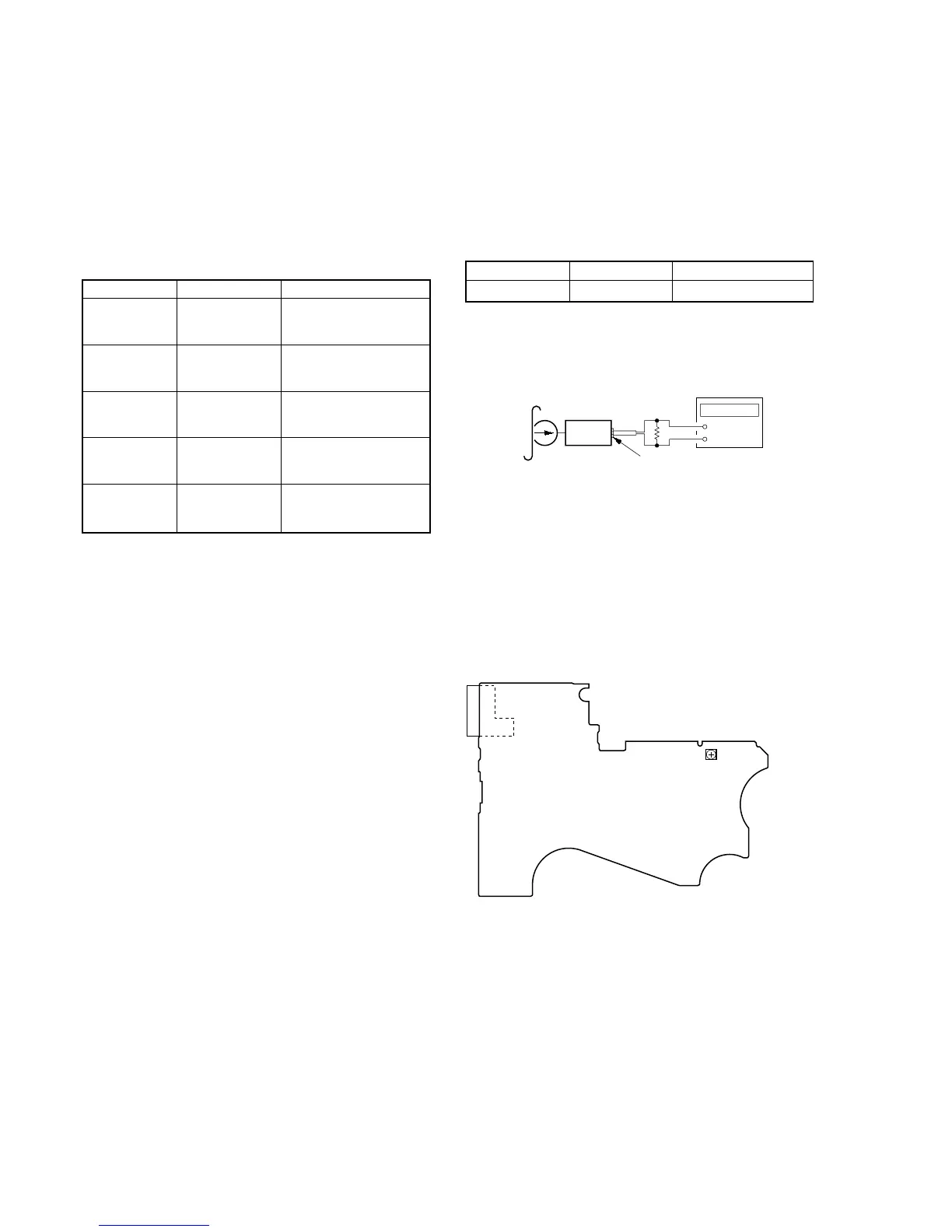

Tape Speed Adjustment

Procedure:

PRECAUTION

1. Specified voltage : 1.3 V (DC)

2. Setting

BL SKIP : OFF

SOUND NORM/MB/GRV : NORM

AVLS : OFF

;NR (WM-EX505 only) : OFF

Test tape

1. Playback WS-48A (tape center) in the FWD state.

2. Adjust RV601 so that the frequency counter reading becomes

3,000 Hz.

Specificated Value: 2,970 to 3,030 Hz

3. Check that deflection of the frequency counter reading between

the beginning and the end of tape is within 1.5% (apporox. 45

Hz).

Adjustment Location:

Type Signal Used for

WS-48A 3 kHz, 0 dB Tape Speed Adjustment

+

–

set

Test tape

WS-48A

(3 kHz, 0 dB)

frequency counte

Loading...

Loading...