– 10 –

SECTION 3

MECHANICAL ADJUSTMENTS

Mode Tension Meter Meter Reading

Forward CQ-403A more than 60 g

Reverse CQ-403R (more than 2.12 oz)

• Tape Tension Measurement

1. Clean the following parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idler

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the power supply

voltage (14.4 V) unless otherwise noted.

• Torque Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C

25 – 55 g•cm

(0.35 – 0.76 oz•inch)

Forward

CQ-102C

1.5 – 4 g•cm

Back Tension (0.02 – 0.06 oz•inch)

Reverse CQ-102RC

25 – 55 g•cm

(0.35 – 0.76 oz•inch)

Reverse

CQ-102RC

1.5 – 4 g•cm

Back Tension (0.02 – 0.06 oz•inch)

FF, REW CQ-201B

50 – 150 g•cm

(0.69 – 2.08 oz•inch)

SECTION 4

ELECTRICAL ADJUSTMENTS

TAPE DECK SECTION 0 dB= 0.775 V

1. The adjustments should be performed in the order given in

this service manual.

2. The adjustments should be performed for both L-CH and

R-CH.

Test Tape

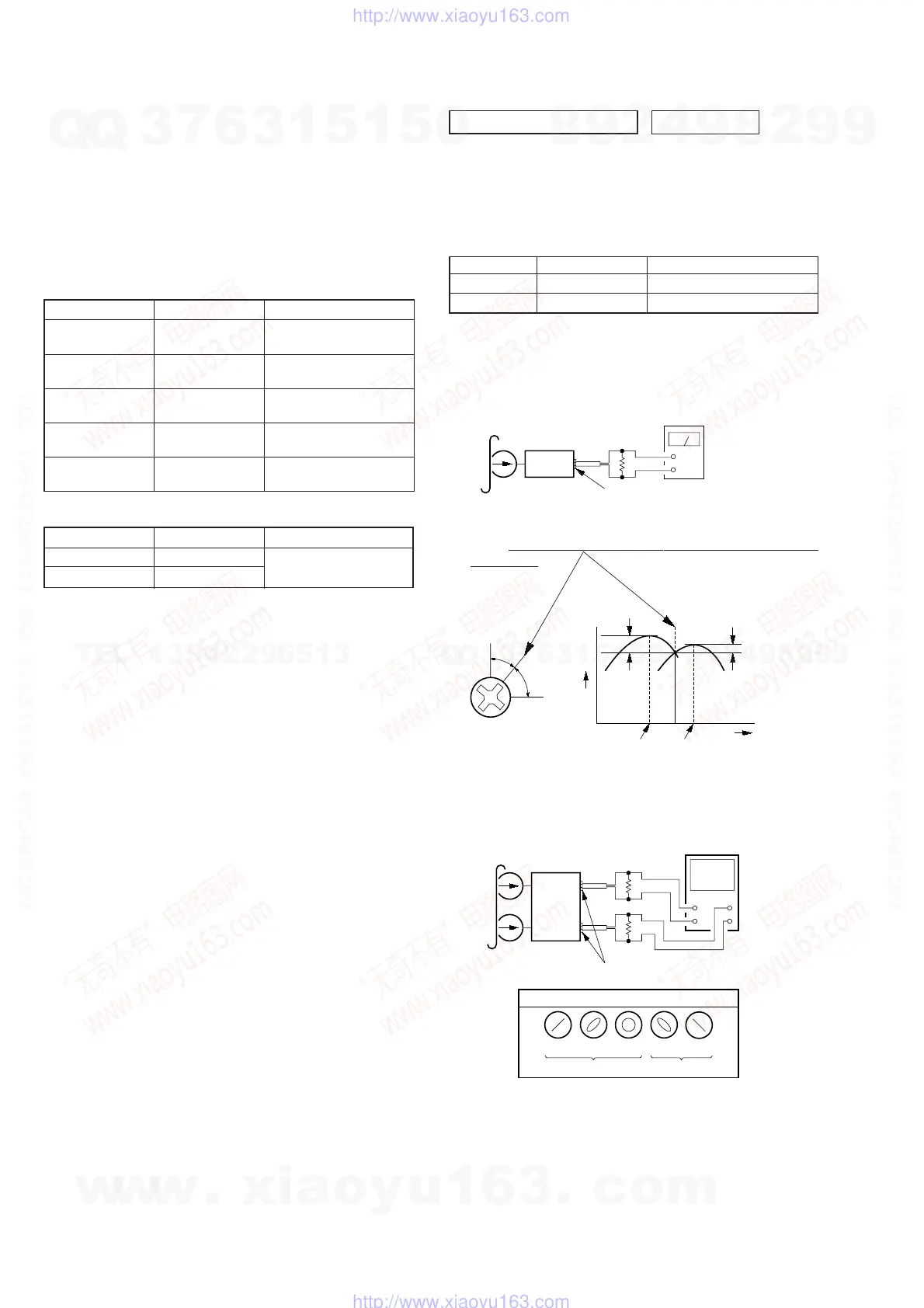

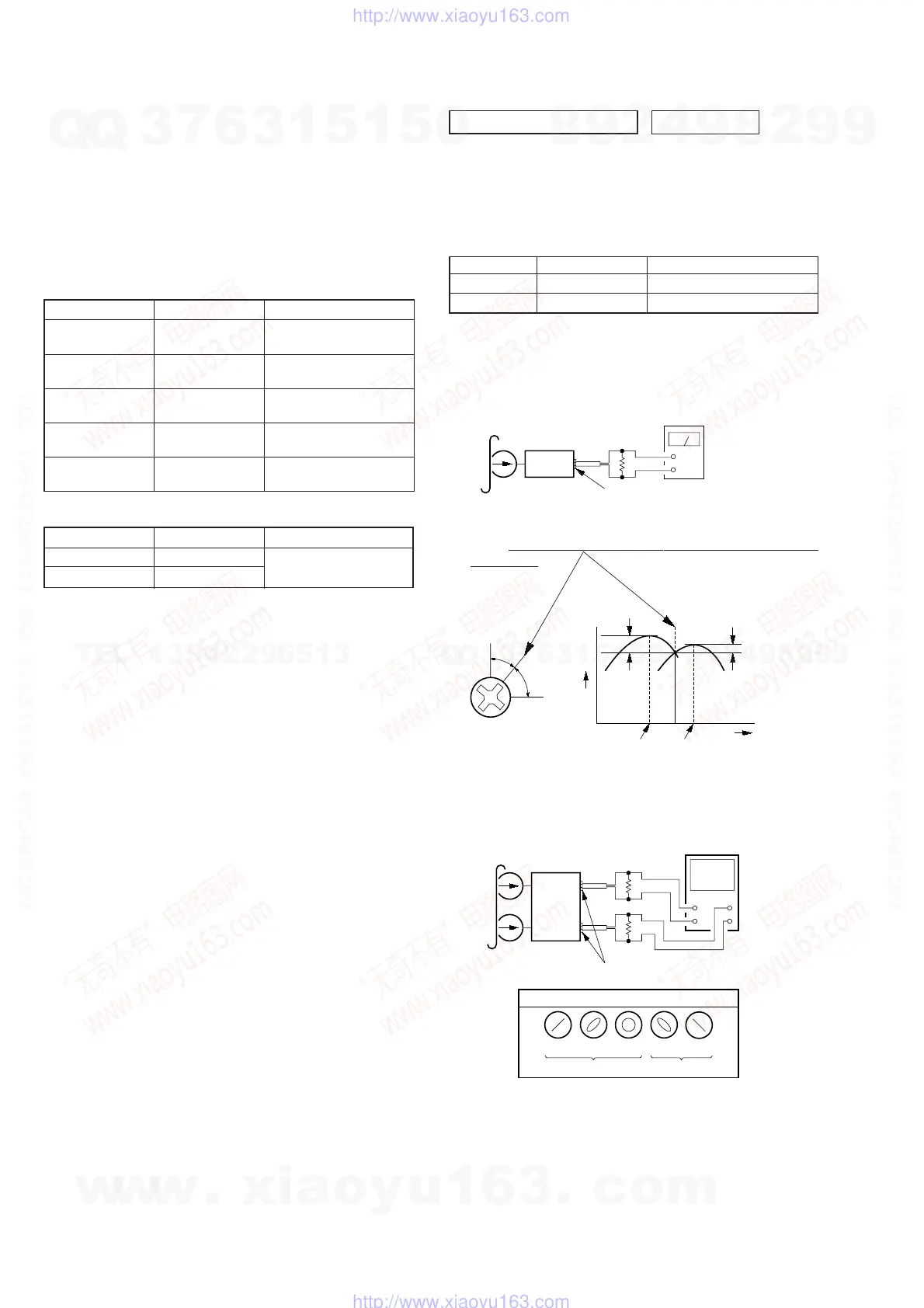

PB Head Azimuth Adjustment

Procedure:

1. Put the set into the FWD PB mode.

2. Turn the screw and check the output peak value. Adjust the

screw

so that the peak value in channels L and R coincides

within 2 dB.

3. Check the phase in the FWD PB mode.

Type Signal Used for

P-4-A063 6.3 kHz, –10 dB head azimuth adjustment

WS-48A 3 kHz, 0 dB tape speed adjustment

screw

position

L-CH

peak

within

2 dB

output

level

L-CH

peak

R-CH

peak

within

2 dB

angl

R-CH

peak

test tape

P-4-A063

(6.3 kHz, –10 dB)

L-CH

R-CH

speaker out terminal

oscilloscope

V

H

+

+

–

–

Screen pattern

in phase

good wrong

45

°

90

°

135

°

180

°

4

Ω

4

Ω

set

level

meter

test tape

P-4-A063

(6.3 kHz, –10 dB)

set

speaker out termina

4

Ω

+

–

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com

Loading...

Loading...