Miniature magnets can also be operated safely at the controller !

Setting the ON and OFF time delay for the level controller

The level of the material in the filling section is measured by the GAN and

GAB trimmers. To increase the material back-up downstream from the sensor,

use the GAB trimmer to lengthen the controller's OFF delay time. Reduce the

GAB time to reduce the back-up of material. The GAN trimmer can now be used

to determine the time that passes from when the last part of the material

leaves the sensor position until the feeder appliance is switched on

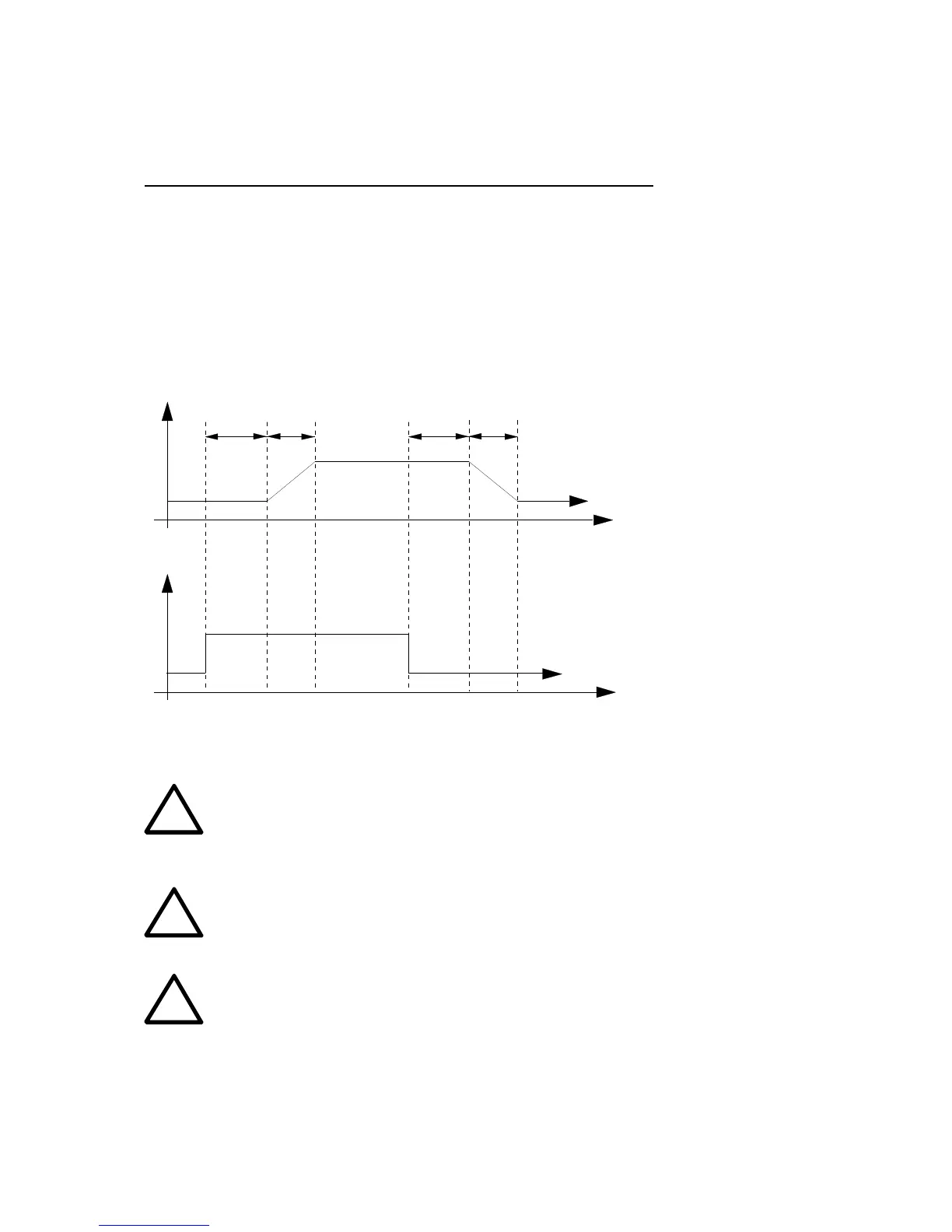

The diagram shows the time sequence in operations with the controller input

low active:

t

t

0

X

V

0

1

G

AN

SA G

AB

SS

0,1-10s 0,5-5s

0,1-10s

0,1-5s

Output voltage

Signal at

control input

3. Warnings

!

!

!

In the case of applications that require the oscillation conveyor

to be switched ON and OFF constantly (e.g. dust switched off, hop-

per control system, etc.), the prescribed controller input must be

used. If the load circuit is disconnected with a switch or a relay

the controller may be damaged.

If the controller is switched on, never insert or remove the plug

at the vibration conveyor being operated. This can damage the ap-

pliance.

Repair work must be carried out by qualified personnel only. We

recommend that repairs are carried out on our premises.

4. Installation

Loading...

Loading...