– 7 –

Inverter Air-to-Water Heat Pump

Glycol/Water System

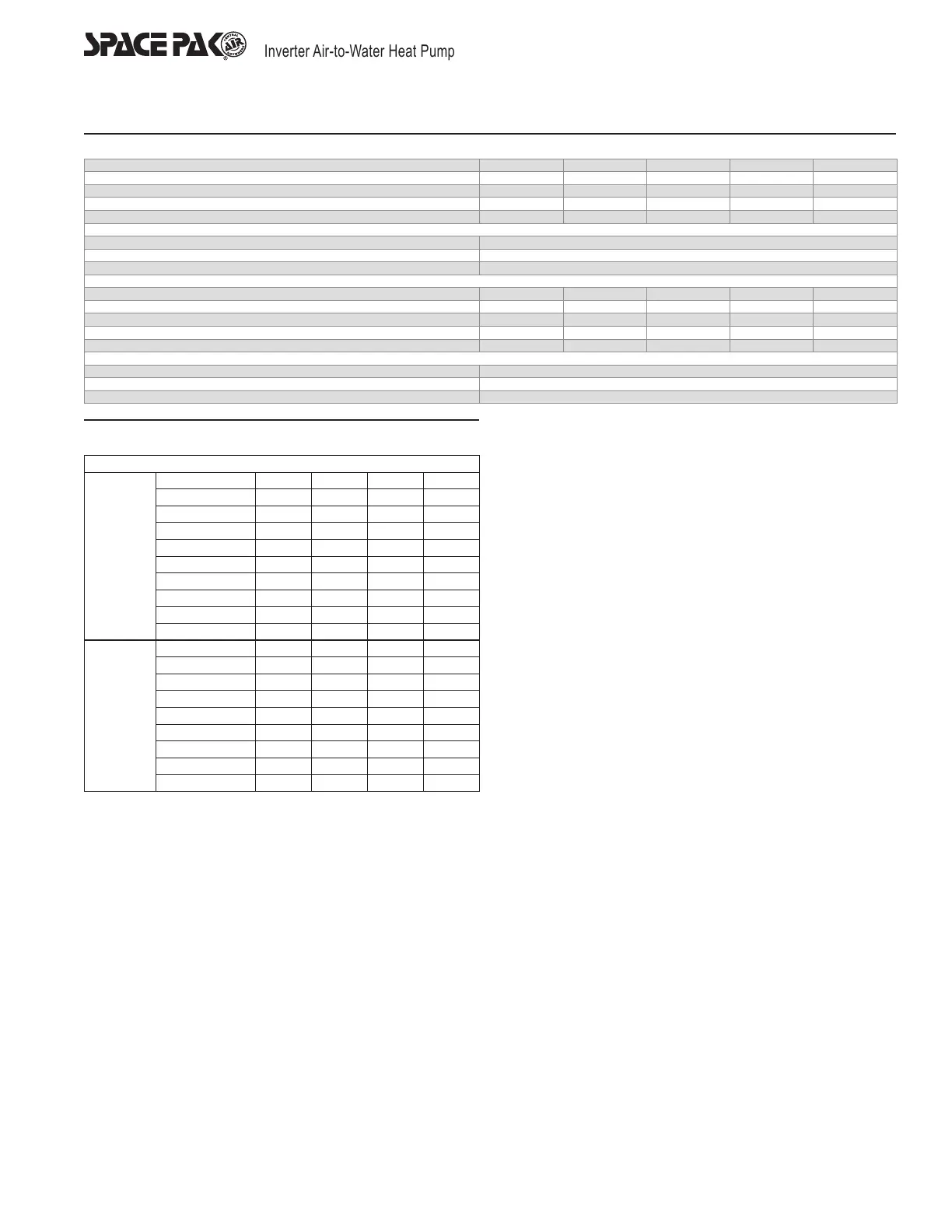

Figure 1 SIM Glycol Concentrations (10% Minimum, 50% Maximum)

Ethylene Glycol % 10 20 30 40 50

Min. Ambient Temp for Operation 23°F/-5°C 14°F/-10°C 2°F/-17°C -13°F/-25°C -36°F/-38°C

SpacePak Capacity Multiplier 0.98 0.96 0.93 0.91 0.89

Pressure Drop Multiplier (Cooling) 1.06 1.12 1.16 1.25 1.36

Pressure Drop Multiplier (Heating) 1.06 1.12 1.16 1.22 1.28

Minimum Expansion Volume / System Volume

Heating and Cooling (Gallons) 1 gallon expansion per 15 gallons system volume

Heating only, HP only (Gallons) 1 gallon expansion per 20 gallons system volume

Heating Only, with Boiler (Gallons) 1 gallon expansion per 15 gallons system volume

Propylene Glycol % 10 20 30 40 50

Min. Ambient Temp for Operation 26°F/-3°C 18°F/-8°C 8°F/-13°C -7°F/-22°C -29°F/-34°C

SpacePak Capacity Multiplier 0.99 0.98 0.96 0.93 0.88

Pressure Drop Multiplier (Cooling) 1.10 1.20 1.34 1.5 1.65

Pressure Drop Multiplier (Heating) 1.10 1.20 1.34 1.46 1.5

Minimum Expansion Volume / System Volume

Heating and Cooling 1 gallon expansion per 15 gallons system volume

Heating only, HP only 1 gallon expansion per 20 gallons system volume

Heating only, with Boiler 1 gallon expansion per 15 gallons system volume

Glycol/Water System Design

Each SIM Heat Pump has a recommended ow that should be

maintained during all times of operation. For the SIM-060, the

recommended ow is 13GPM at which the head loss is 25ft W.C,

11PSI or 73kPa. For the SIM-036 the recommended water ow is

7GPM at which the head loss is 6 ft W.C. or 6 P.S.I. These head loss

values are based upon pure water, see Figure 1 for multipliers to

correct for various concentrations of anti-freeze solution.

Note: these are the recommended ow values. Should the ow drop

signicantly below this value, the heat pump will shut down and

display the code FL on the display. This is not an indication of a fault

in the heat pump, but rather points to insufcient pump or plumbing

capacity, or air trapped within the system.

System Volume and Expansion Volume

To ensure smooth temperature control and minimize cycling of

refrigeration system, all installations must have total circulating

volumes equal to or greater than 7-1/2 gallons per nominal ton

of the unit performance (The greater of either heating or cooling

produced). In other words, in the case of a four ton heat pump the

minimum total system volume is 4x7-1/2=30 gallons. Multiple heat

pump installations that are operating in a staged conguration follow

the same rule, so that only a single heat pump tonnage needs to be

considered. Additionally, the system requires an expansion volume

(air) to compensate for the change in volume of the glycol mixture

as it heats and cools, see Figure 1 for expansion volume.

A typical multiple heat pump installation may actually have a volume

far greater than the minimum required, and it is this entire volume

that must be considered when sizing the expansion tank.

Note that the nominal expansion tank volume is not the same as the

expansion volume. If the actual air volume is not published, consider

it to be no more than half the nominal volume.

As an example, a four ton nominal heat pump, used for both heating

and cooling, requires a minimum of thirty gallons of circulated

system volume. A 40 gallon buffer tank is selected for best operation.

When the system installation is complete, the total liquid volume

of plumbing, air handlers, and heat pump is 45 gallons. (Note the

expansion tank, no matter how large, is not considered circulated

volume) This requires an acceptance volume of 3 gallons. If the

acceptance volume is not specied, assume it is 50% of the total

volume. Therefore, this system would require an expansion tank of 3

gallons acceptance volume, or six gallons nominal full volume.

Air Separator

Locate at least one high efciency air separator as shown in the

piping to remove any air from the system.

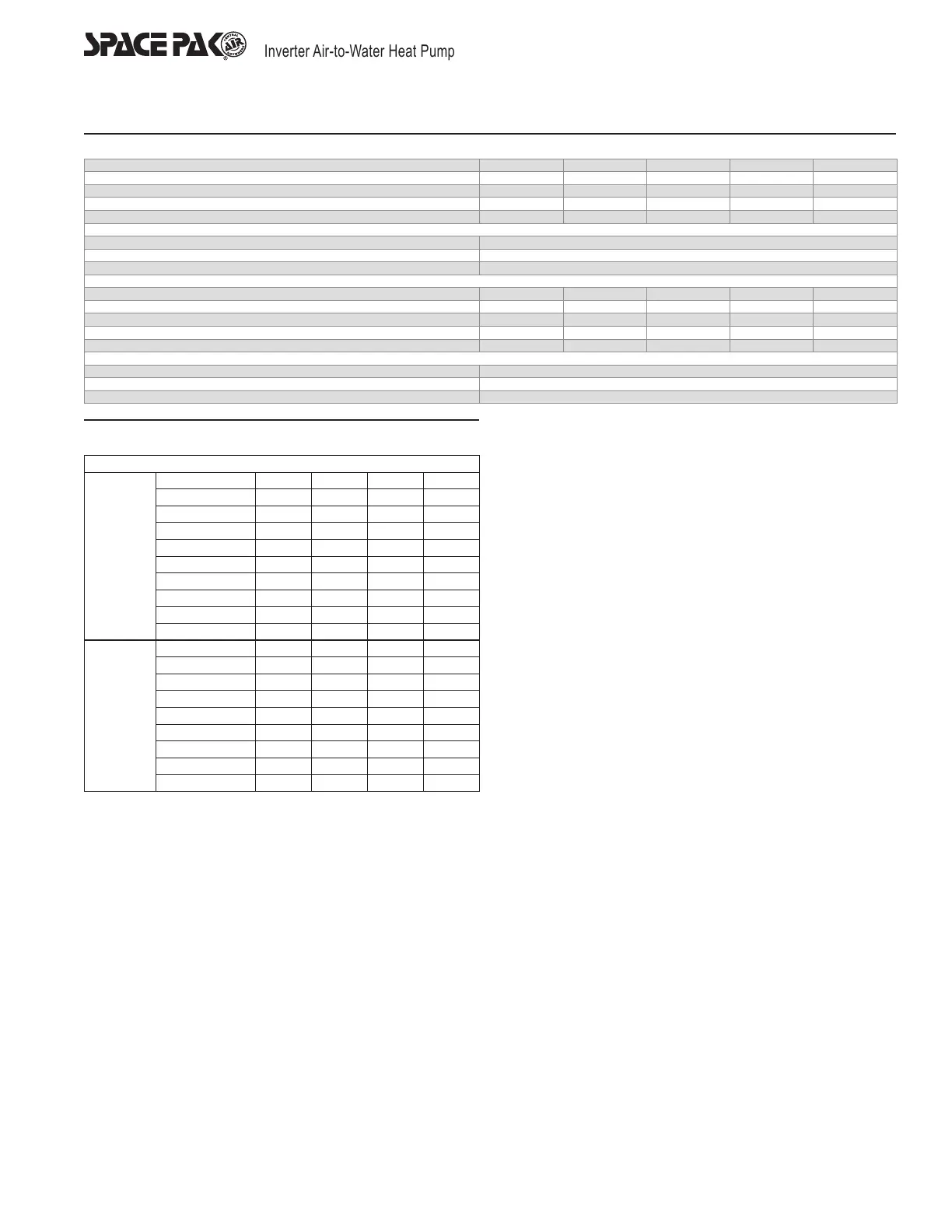

Figure 2

Piping Pressure Losses*

Pressure Drop, Ft H2O/100ft*

Pex

Pipe

Flow Rate GPM 1" 1-1/4" 1-1/2" 2"

6 5.5 1.7 - -

7 7.2 2.5 1.5 -

8 9.1 3.4 1.8 -

9 11.1 4.3 2.1 0.5

10 13.4 5.2 2.4 0.6

11 15.9 6.2 2.8 0.7

12 18.5 7.2 3.2 0.9

14 - 9.4 4.2 1.2

16 - 11.8 5.4 1.6

Copper

Pipe

(Type L)

6 1.0 - - -

7 1.4 0.5 - -

8 1.8 0.7 - -

9 2.2 0.8 0.3 -

10 2.7 1.0 0.4 -

11 3.2 1.2 0.5 0.1

12 3.8 1.4 0.6 0.1

14 - 1.8 0.8 0.2

16 - - 1.0 0.3

*Remember to check the CV rating of your ttings and valves to

make sure you're getting the required ow through the equipment.

Loading...

Loading...