16

P09588, Rev. 6 CO # 1848

should be intact and there should be no evidence of bulging, stretching, crimping,

cracking, or discoloration, especially at the ends, where the cord is attached to the plug

body and the control unit

5. Regularly inspect as parts of the bed frame, motor, mattress and controller, and the floor

beneath and near the bed for build-up of dust and lint.

6. Inspect the cover of the control panel to assure that the covering is not cracked or

damaged, allowing liquids or other conductive material to penetrate to the switches.

7. Report any unusual sounds, burning odors, or anything unusual to maintenance

personnel. Discontinue use of the power cord immediately and contact Span-America

Medical Systems for replacement.

Mattress

Inspect the covers and zipper area for signs of damage, puncture, or wear that could result in

fluid pass-through. If the cover is stained, soiled, or torn, inspect the internal components for

signs of contamination. If contamination is evident, quarantine the mattress and remove from

service following infection control procedures.

You may use the Preventive Maintenance Log provided on the last page (24) of this manual to

monitor and document regular inspection and maintenance of your PressureGuard

Custom Care

Surfaces.

EMC

Electric devices may interact due to electro-magnetic radiation. We recommend a safety

distance of at least one –meter, especially for sensitive equipment.

Upon request, we will provide you with a table for more detailed information.

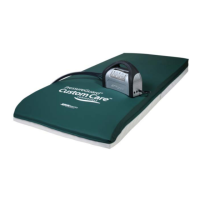

Guidance and manufacturer’s declaration – electromagnetic emissions

The 6500 is intended for use in the electromagnetic environment specified below. The customer or the user of the 6500

should assure that it is used in such an environment.

Electromagnetic environment – guidance

RF emissions

CISPR 11

Group 1

The 6500 uses RF energy only for its internal

function. Therefore, its RF emissions are very

low and are not likely to cause any

interference in nearby electronic equipment.

The 6500 is suitable for use in all

establishments, including domestic

establishments and those directly connected

to the public low-voltage power supply network

that supplies buildings used for domestic

purposes.

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations/

flicker emissions

Complies

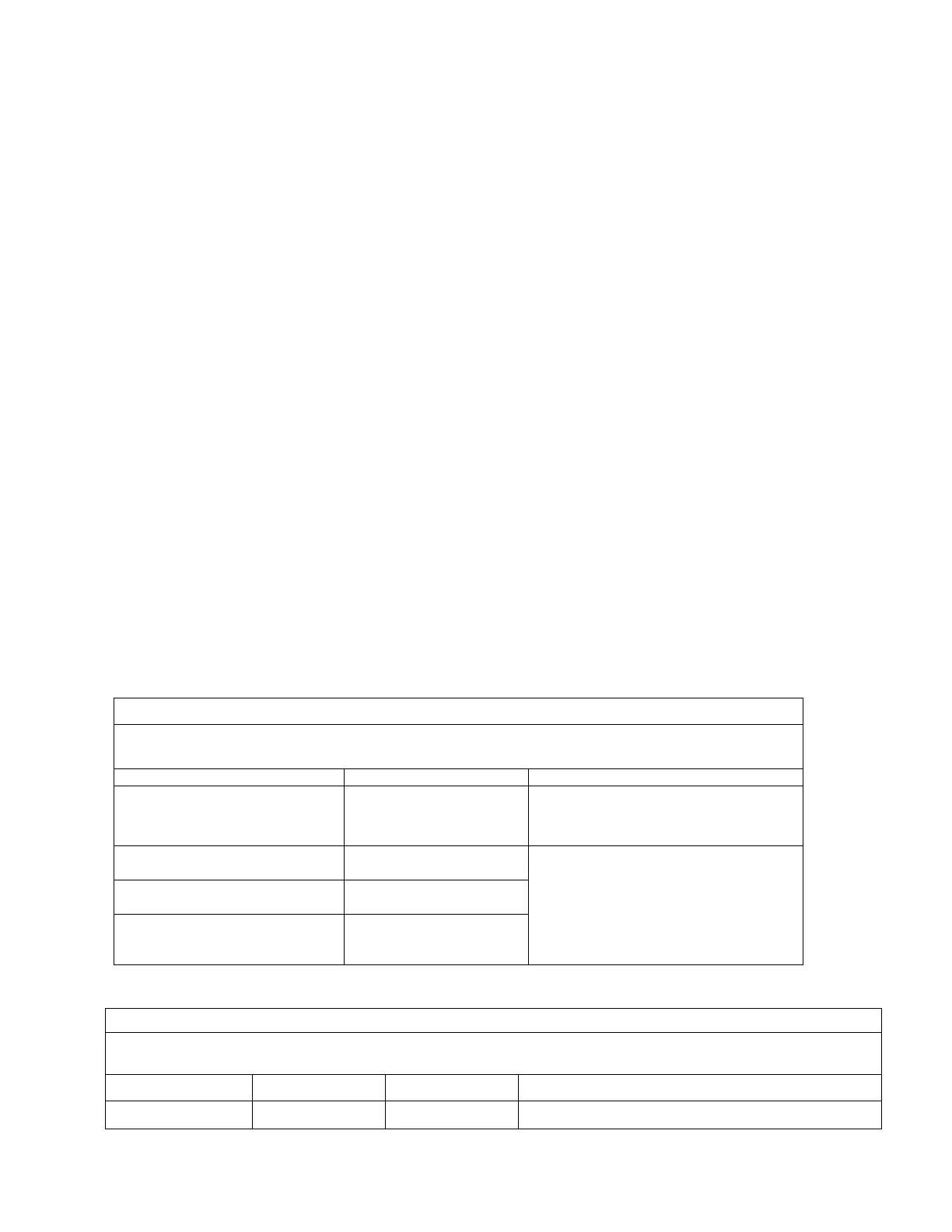

Guidance and manufacturer’s declaration – electromagnetic immunity

The 6500 is intended for use in the electromagnetic environment specified below. The customer or the user of the 6500 should assure that it is used in such

an environment.

Electromagnetic environment – guidance

Electrostatic

±6 kV contact ±6 kV contact

Floors should be wood, concrete or ceramic tile. If floors are covered

with synthetic material, the relative humidity should be at least 30 %.

Loading...

Loading...