Speck Pumpen Vakuumtechnik GmbH

zertifiziert: DIN EN ISO 9001

Supplementary Operating Instructions for Explosion Protection

4

For dust explosion protection the surface temperature has to be lower than 2/3 of the ignition temperature

in °C of the dust-air-mixture and 75 K below the glow temperature of a dust coat of 5 mm thickness.

4 Identification

The identification of the compressor with the label and the corresponding classification applies only

to the liquid-ring compressor.

Example: II 1G IIB T4 for explosive gas

Example: II 1D T 120° for explosive dusts with a maximum admissible surface

temperature of 120°C

All external equipment and components (coupling, motor, etc.) must at least satisfy the classifications

specified by the manufacturer of the compressor, be suitable for the respective zone and exhibit an

appropriate authorization and identification of the manufacturer of the respective equipment. This is

ensured with acquisition of the complete compressor with drive and control systems.

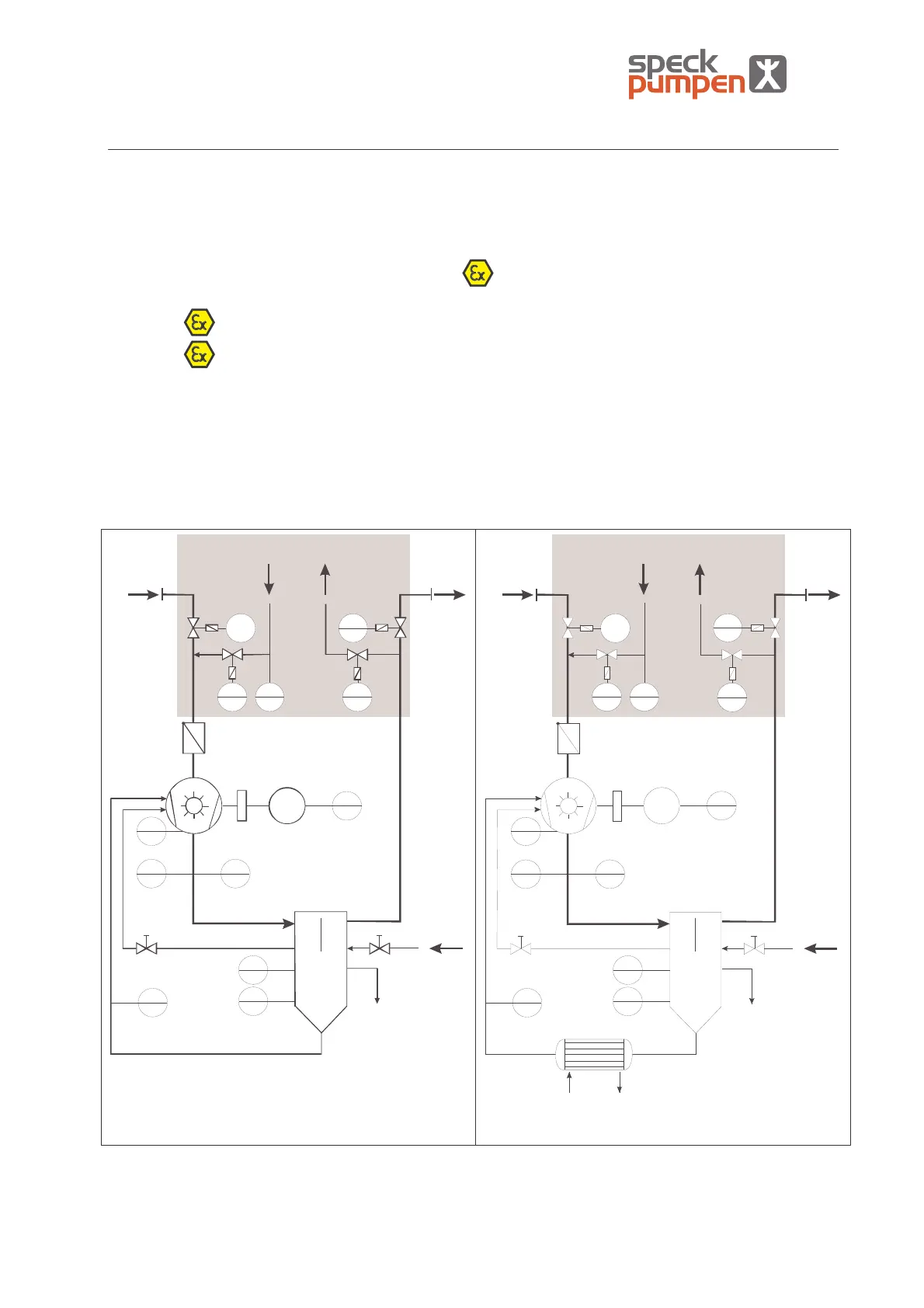

5 Permissible operating modes

Overflow

Fresh liquid

Inert gas

Anti-cavitation

protection

LS-

02

LS-

01

LS-

03

SO+

00

TS+

05

PS+

06

FS-

04

GO

11

GO

12

UV

13

UV

14

FS-

14

The inert gas flushing is only necessary for

gases and vapors, which contain hydrogen

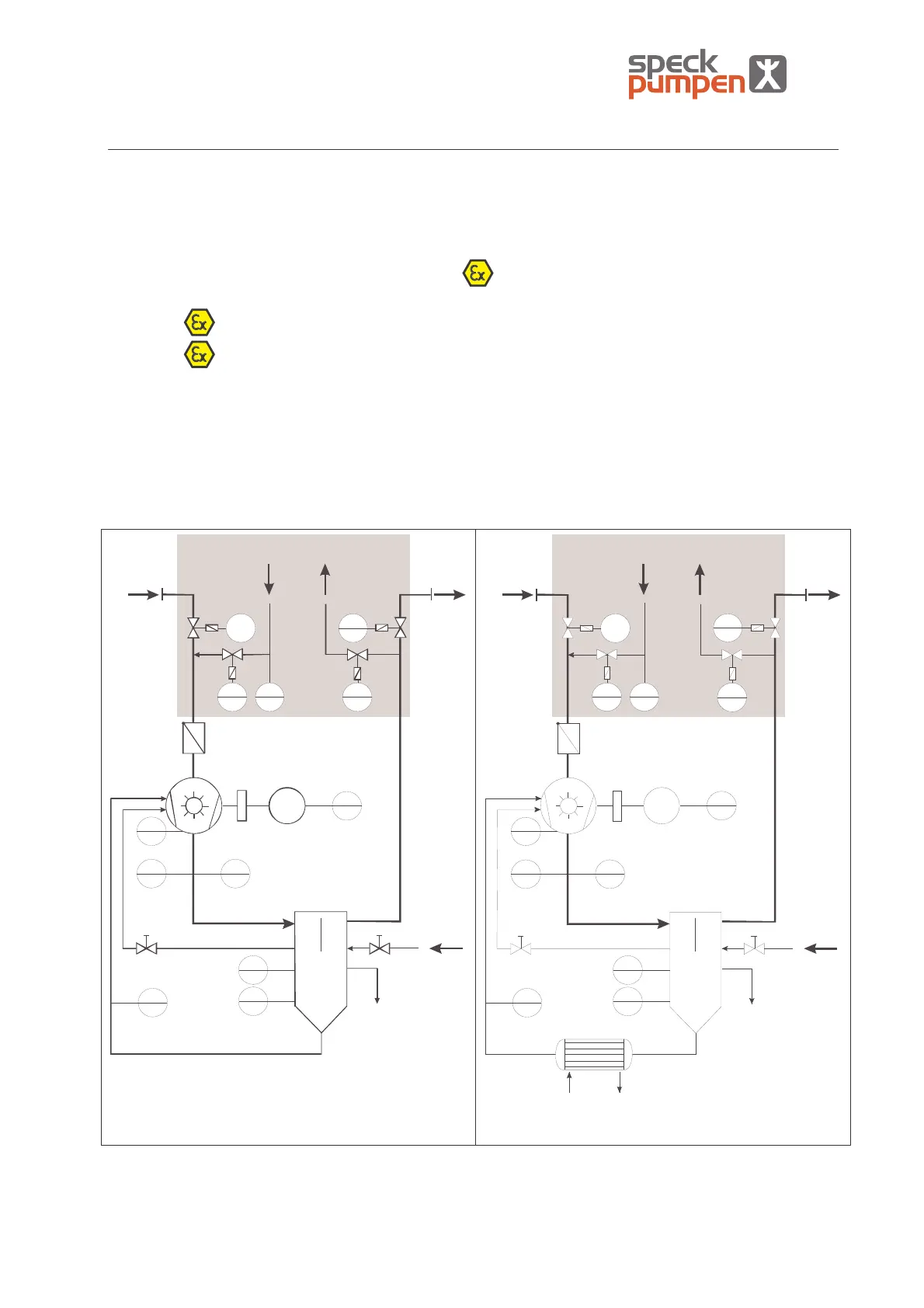

Overflow

Fresh liquid

Inert gas

Anti-cavitation

protection

LS-

02

LS-

01

LS-

03

SO+

00

TS+

05

PS+

06

FS-

04

GO

11

GO

12

UV

13

UV

14

FS-

14

The inert gas flushing is only necessary for

gases and vapors, which contain hydrogen

Fig. 5.1. open circuit cooling

Fig. 5.2. closed circuit cooling

Loading...

Loading...