IM-S21-01 CH Issue 7

10

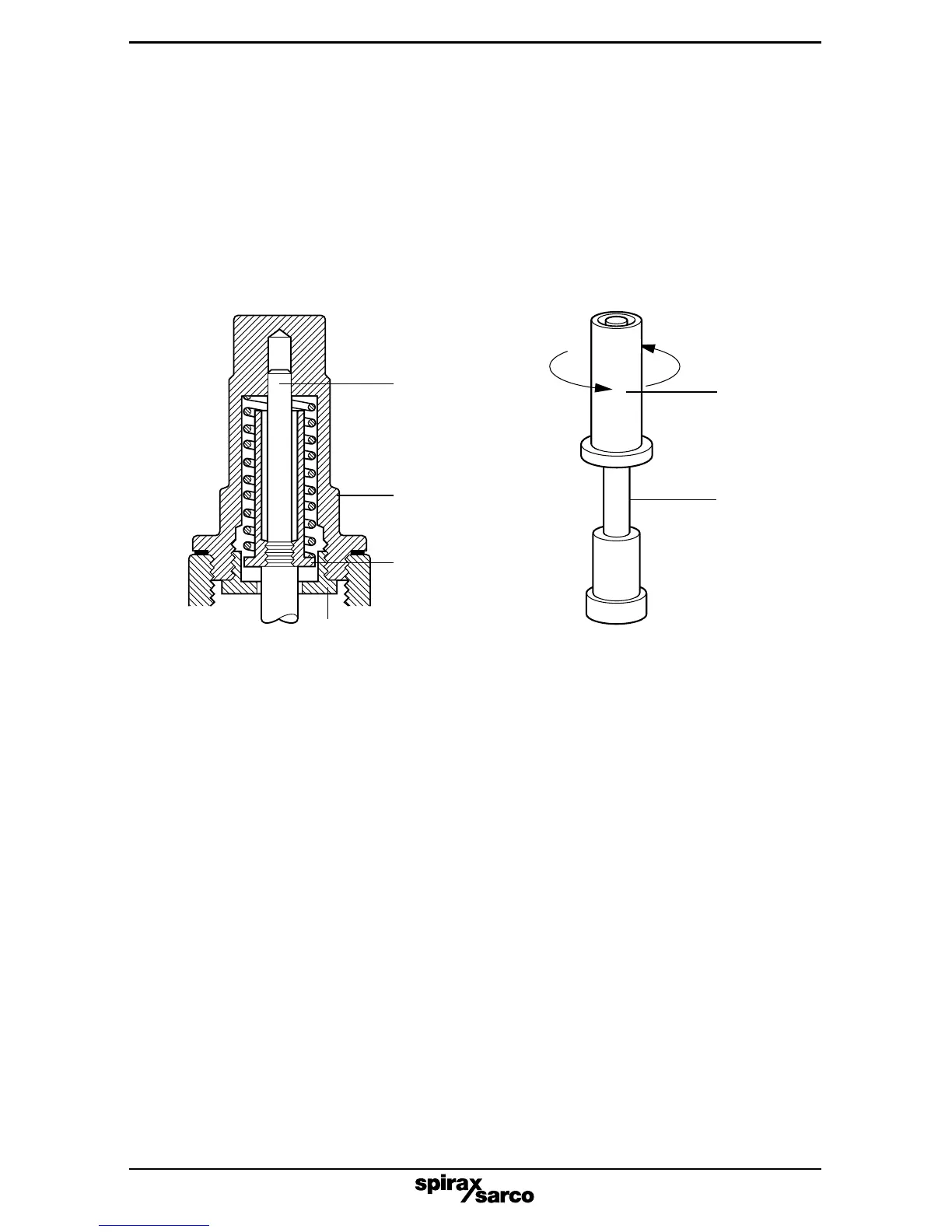

Valve

stem

Fusible

device

Fig. 7

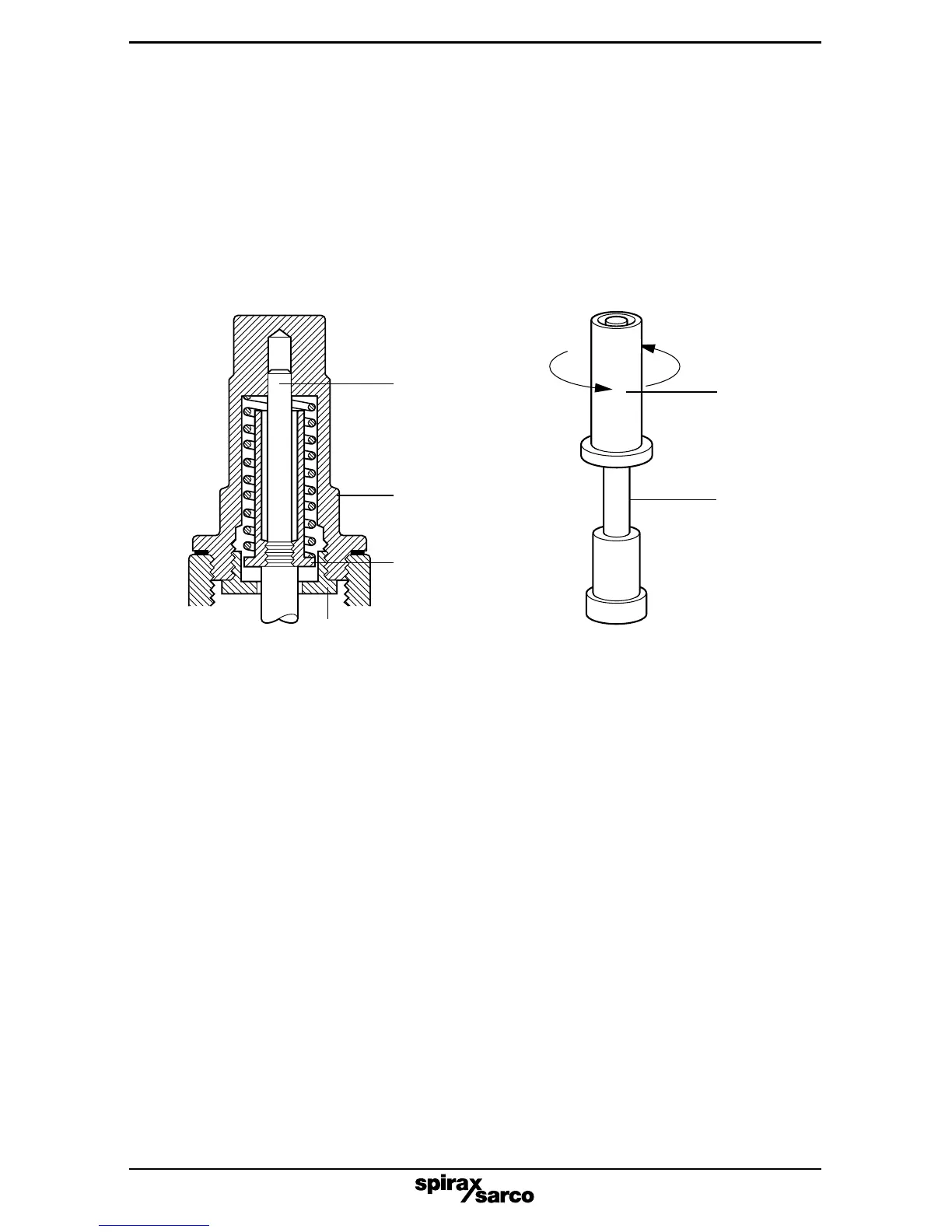

Fig. 8

4.4 SBRA valve with fusible device (refer to Figures 7 and 8)

Replacing or resetting the fuse:

- Isolate the valve and unscrew the bonnet (see Figure 7).

- Unscrew the retaining nut and withdraw the valve, valve stem, fuse and spring assembly.

- The fuse may now be unscrewed from the valve stem and the new one fitted (see Figure 8).

Alternatively the existing fuse may be reset after dismantling as above, by immersing it in hot

water at a temperature above its fusing point 80°C (176°F) on the standard fuse.

When the fuse solder head reaches a fluid state the two cylinders can be pushed together until

the ends are flush. Allow to cool and refit.

4.5 KA61, KA63 and KC63 valves (refer to Figure 9)

Firstly remove the control system sensor from the plant and allow to cool.

SA controls:

- Disconnect the actuator from the valve.

- Before attempting to carry out any repairs, make sure that the valve is fully isolated.

- It is important to always renew the complete assembly as listed above and to make sure that

all of the joint faces are clean.

How to replace the valve seat assembly

Remove the bonnet assembly and unscrew the head/bellows assembly X from the bonnet.

KC63:

- The complete head / bellows assembly can now be withdrawn and a new assembly fitted.

KA63 and KC63:

- Remove the circlip C, washer U, head A and seal B and refit the parts in reverse order

ensuring that the circlip is correctly located in the groove.

KA61:

- The complete head A can now be withdrawn and a new assembly fitted.

- Unscrew the valve seat D and replace with a new seat ring and seat gasket.

- Lightly coat all the gaskets with a suitable jointing compound before fitting.

- Refit the bonnet assembly using new gaskets, taking care to tighten the bonnet nuts evenly.

Valve

stem

Bonnet

Retaining nut

Fusible

device

Fig. 9

Loading...

Loading...