IM-P186-03 CH Issue 4

9

3.2 Start-up and adjustment for the SRV2S

Before final installation, all pipework should be thoroughly 'blown through' to remove dirt,

surplus

jointing material, etc.

Pressure

adjustment is made by turning the adjustment handwheel clockwise to increase

pressure

and anticlockwise to reduce pressure.

With

the upstream stop valve fully open and the downstream stop valve closed, slowly

increase

the downstream pressure by turning the adjustment handwheel clockwise until the

desired

pressure (shown on the downstream pressure gauge) is achieved.

Slowly open the downstream stop valve.

Under normal flow condition, the reduced pressure setting will fall slightly, but will control

under 'dead end' co ons. If required the pressure setting can be increased by readjusting the

SRV2S control. There will be a slight increase in set pressure under 'No-load' conditions.

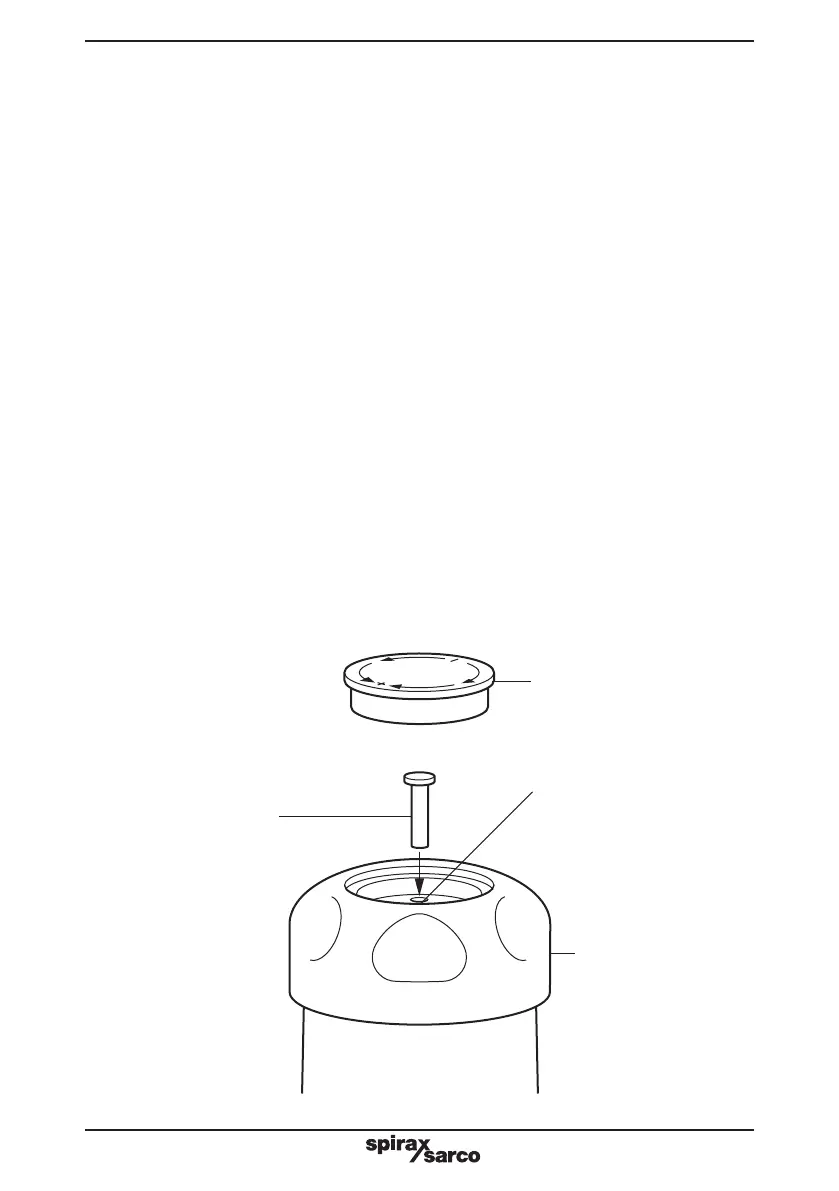

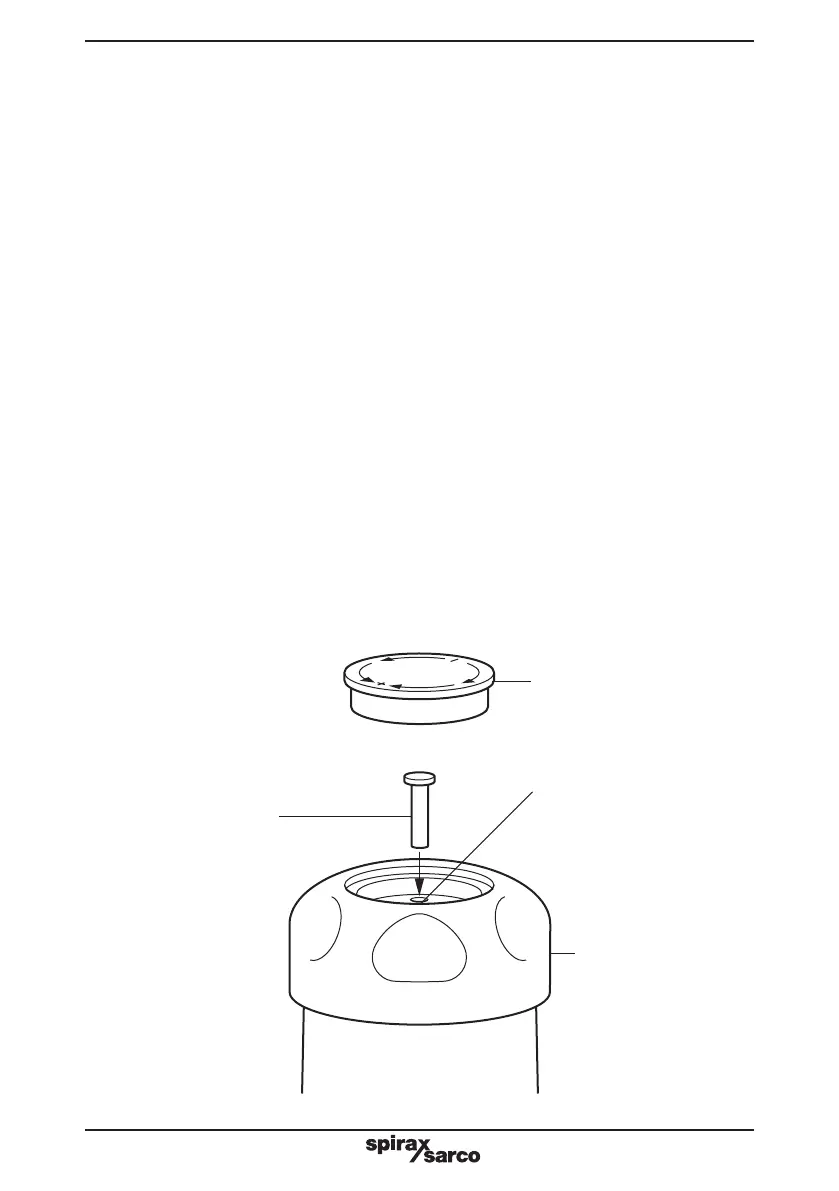

3.3 How to make the SRV2S tamper-proof:

- When the required set pressure has been achieved, lift out the coloured spring range ID

disc (grey, green or orange) from the adjustment handwheel recess. This is carried out by

inserting a small screwdriver blade under the edge of the ID disc.

- A small loose pin will be found in the recess in the adjustment handwheel.

- This tamper-proof pin is inserted into the locking hole 'A', and into one of a ring of 10 matching

holes in the top of the spring housing. The SRV2S is now tamper-proof.

- Replace the coloured spring range ID disc firmly into the recess of the adjustment

handwheel.

A

Fig. 3

Spring range ID disc

Tamper-proof pin

Adjustment handwheel

Loading...

Loading...