IM-P186-03 CH Issue 4

8

3. Installation

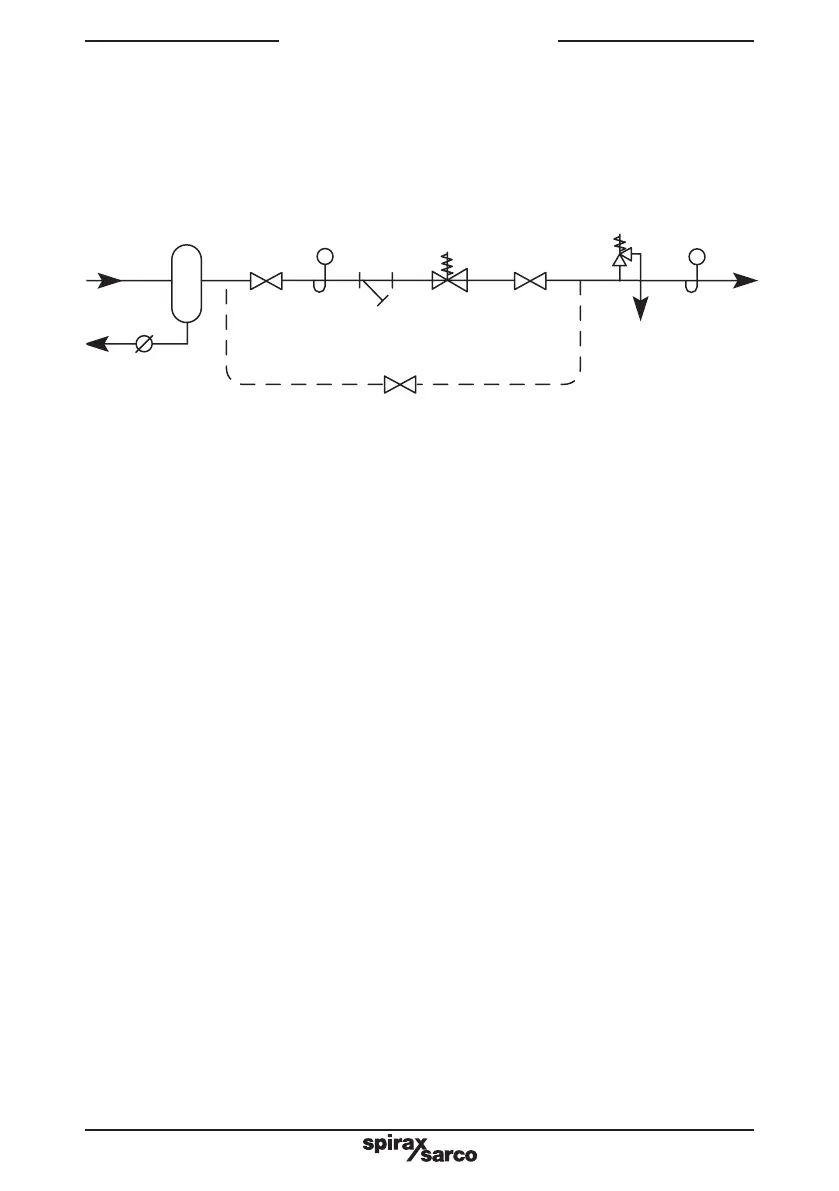

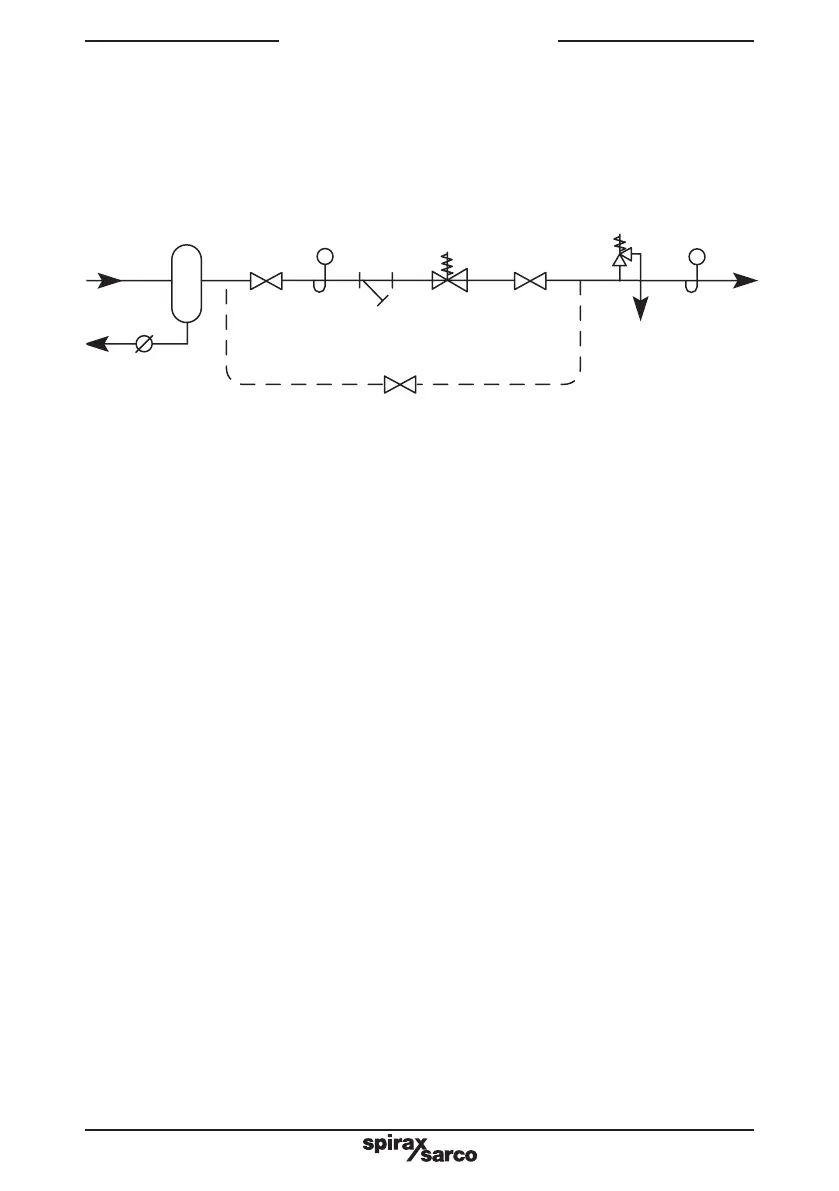

A Steam trap

B Strainer

C Isolating valve

D Safety valve

E Pressure gauge

F Separator

3.1 General installation

Always install the SRV2S with the flow direction arrow (on the body) pointing downstream.

The

SRV2S pressure reducing valve is available as follows:

Screwed

½", ¾" and 1" BSP (BS 21 Rp) or

Flanged

DN15, DN20 and DN25 EN 1092 PN25 and ANSI 150.

The

Spirax Sarco SRV2S pressure reducing valve should always be fitted in a horizontal

pipeline. The adjustment head may be above or below the valve.

Isolating

valves should be installed, upstream and downstream of the SRV2S, with a clear run

of

8 to 10 pipe diameters on either side.

It

is important that line stresses, caused by expansion or inadequate pipe support, are not

imposed

on the valve body.

Upstream

and downstream piping must be of ample size to avoid undue pressure drop.

Any

reduction in line size should be made using eccentric reducers.

Fitting

a strainer on the upstream side will give additional protection to the valve. Install the

strainer

on its side to prevent the body filling with water, which will reduce the effective

screening

area. If the steam supply is wet a separator/trap set should be installed upstream.

Alternatively,

an adequate drain pocket and a trap from the Spirax Sarco range should

be fitted.

A pressure gauge is essential on the downstream pipework to allow setting of the operating

pressure.

It is an advantage to have a gauge on the upstream side of the valve, as well.

Safety valve

A safety valve should be fitted to protect the downstream equipment from excessive pressure

(to

meet local standards). It should be set to lift below the safe working pressure of the

downstream

equipment, and will normally be sized to pass the full capacity of the SRV2S should

it fail in the fully open position. The safety valve set pressure should take account of its reseat

characteristic

and the 'No-load' pressure setting of the SRV2S. Discharge pipework should

be

taken to a safe place.

Note: Before actioning any installation observe the 'Safety information' in Section 1.

Note: If you experience difficulty with installation or operation of this equipment please contact:

Spirax-Sarco Limited, Charlton House, Cheltenham, Gloucestershire, GL53 8ER

Tel: +44 (0)1242 521361, Fax: +44 (0)1242 573342

Fig. 2 Recommended installation

C1

C2

C3

F

A

B

SRV2S

D

E2

E1

Loading...

Loading...