IM-P068-24 ST Issue 56

2.2 Sizes and pipe connections

TD42 ", ½"LC, ½" and ¾" screwed BSP or API

TD42A ", ½"LC, and ½" screwed BSP (BS 21 parallel) or API

TD42H ½", ¾" and 1" screwed BSP or NPT

TD42L ", ½", ¾" and 1" screwed BSP or NPT

TD42HA ½" screwed BSP or NPT

TD42LA ", ½", ¾" and 1" screwed BSP or NPT

TD42LCA ½" screwed BSP

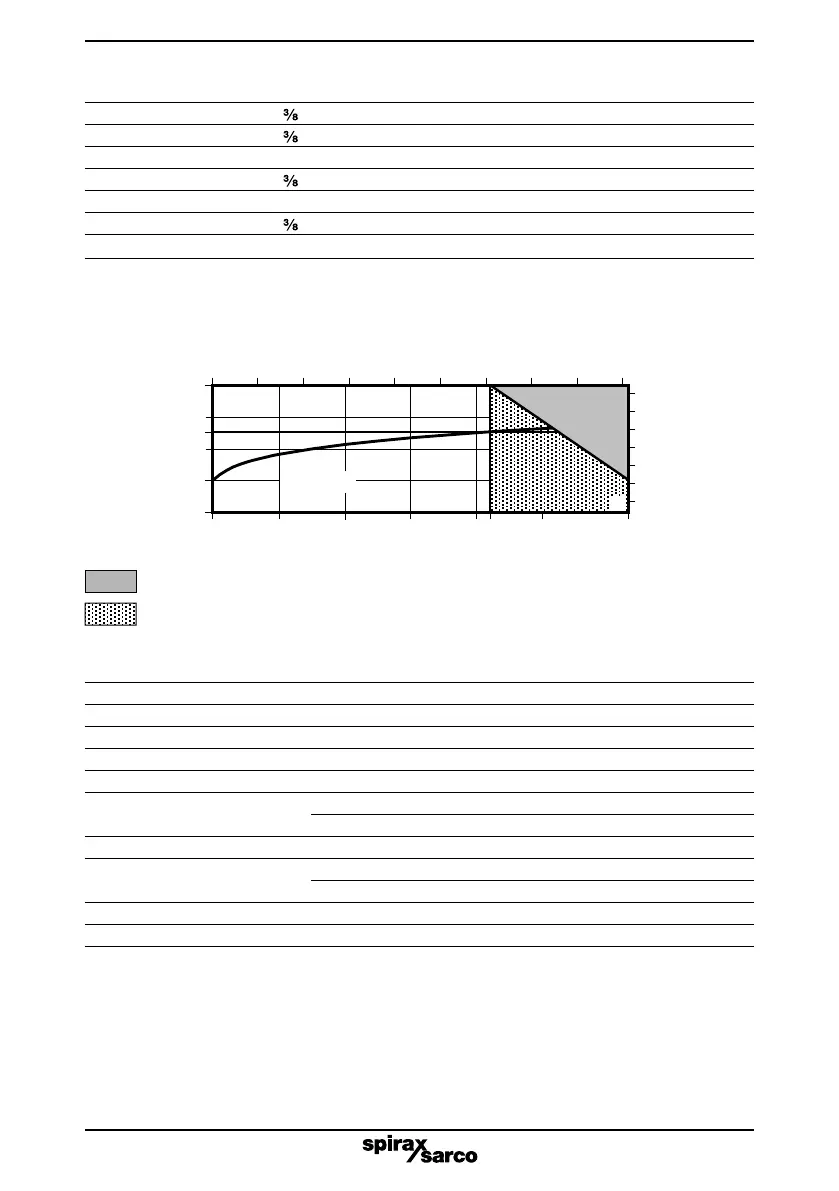

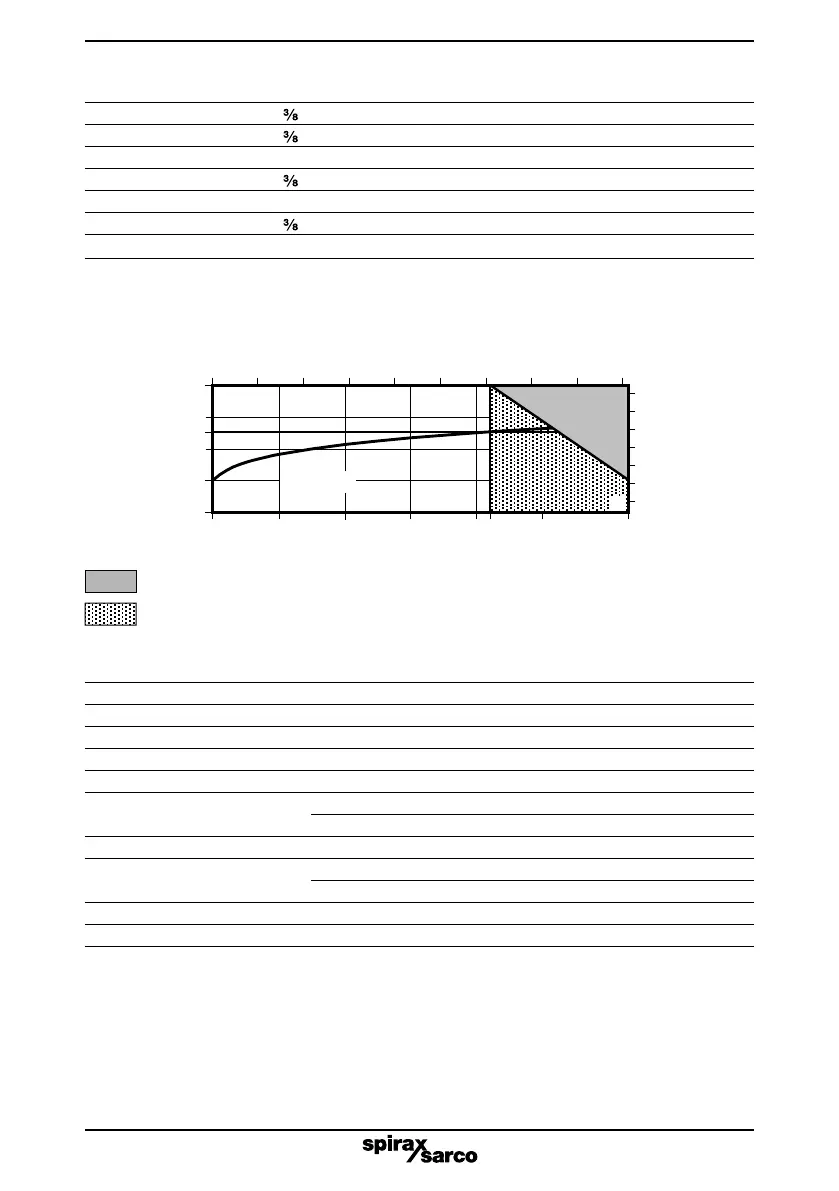

2.3 Pressure / temperature limits (ISO 6552)

Pressure bar g

The product must not be used in this region.

For optimum product performance the PMO should not exceed 42 bar g.

A - C TD42L and TD42H

B - C TD42LA and TD42HA

Body design conditions PN63

PMA Maximum allowable pressure 63 bar g @ 100

°C (914 psi g @ 212°F)

TMA Maximum allowable temperature 400°C @ 42 bar g (752°F @ 609 psi g)

Minimum allowable temperature 0°C (32°F)

PMO Maximum operating pressure 42 bar g (609 psi g)

TMO

Maximum operating

TD42L and TD42H 400°C @ 42 bar g (752°F @ 609 psi g)

temperature

TD42LA and TD42HA 255°C @ 42 bar g (491°F @ 609 psi g)

Minimum operating temperature 0°C (32°F)

Minimum inlet pressure

TD42L and TD42H 0.25 bar g (4 psi g)

for satisfactory operation

TD42LA and TD42HA 0.80 bar g (12 psi g)

PMOB Maximum operating backpressure should not exceed 80% of the upstream pressure

Designed for a maximum cold hydraulic test pressure of: 95 bar g (1378 psi g)

Temperature °C

Steam

saturation

curve

A

B

C

Pressure psi g

Temperature °F

Loading...

Loading...