IM-P068-24 ST Issue 5 7

3. Installation

Note:

Before actioning any installation observe the 'Safety information' in Section 1.

Referring to the Installation and Maintenance Instructions, name-plate and Technical

Information Sheet, check that the product is suitable for the intended installation:

3.1 Check materials, pressure and temperature and their maximum values. If the maximum

operating limit of the product is lower than that of the system in which it is being fitted,

ensure that a safety device is included in the system to prevent overpressurisation.

3.2 Determine the correct installation situation and the direction of fluid flow.

3.3 Remove protective covers from all connections and protective film from all

name-plates, where appropriate, before installation on steam or other high temperature

applications.

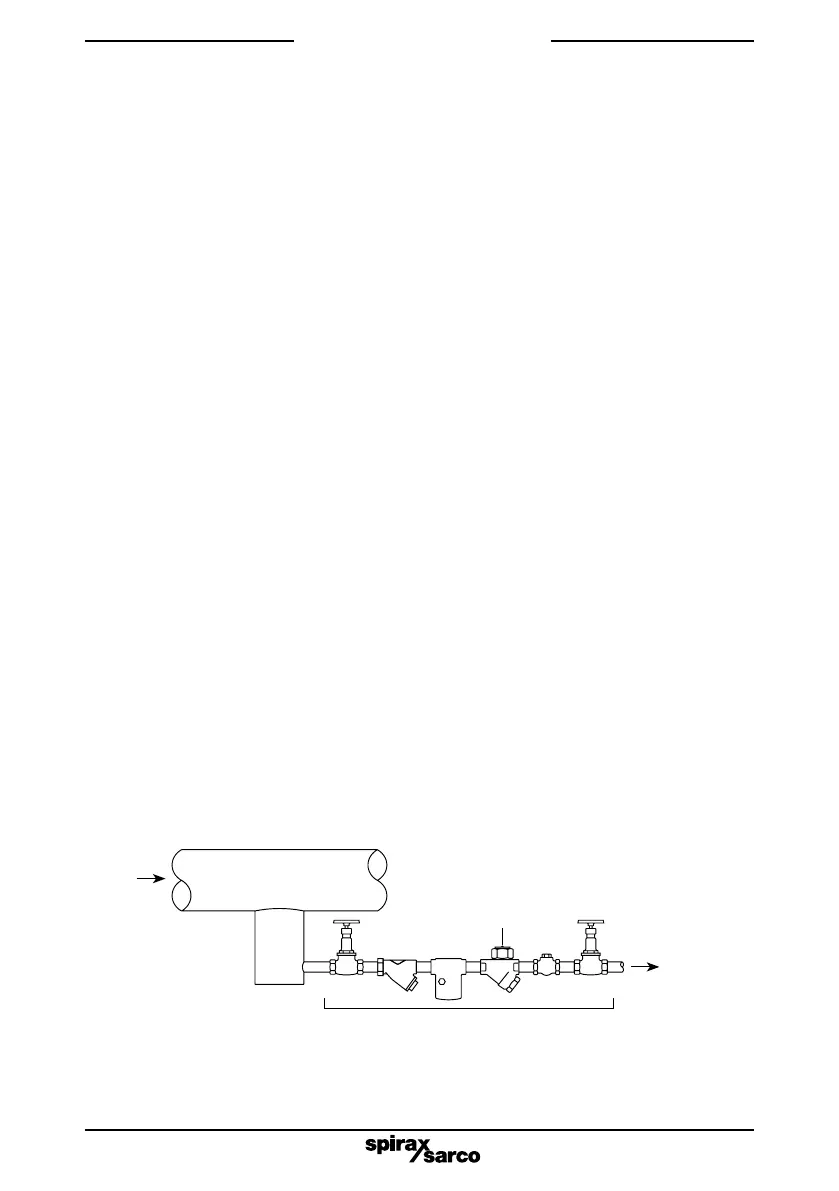

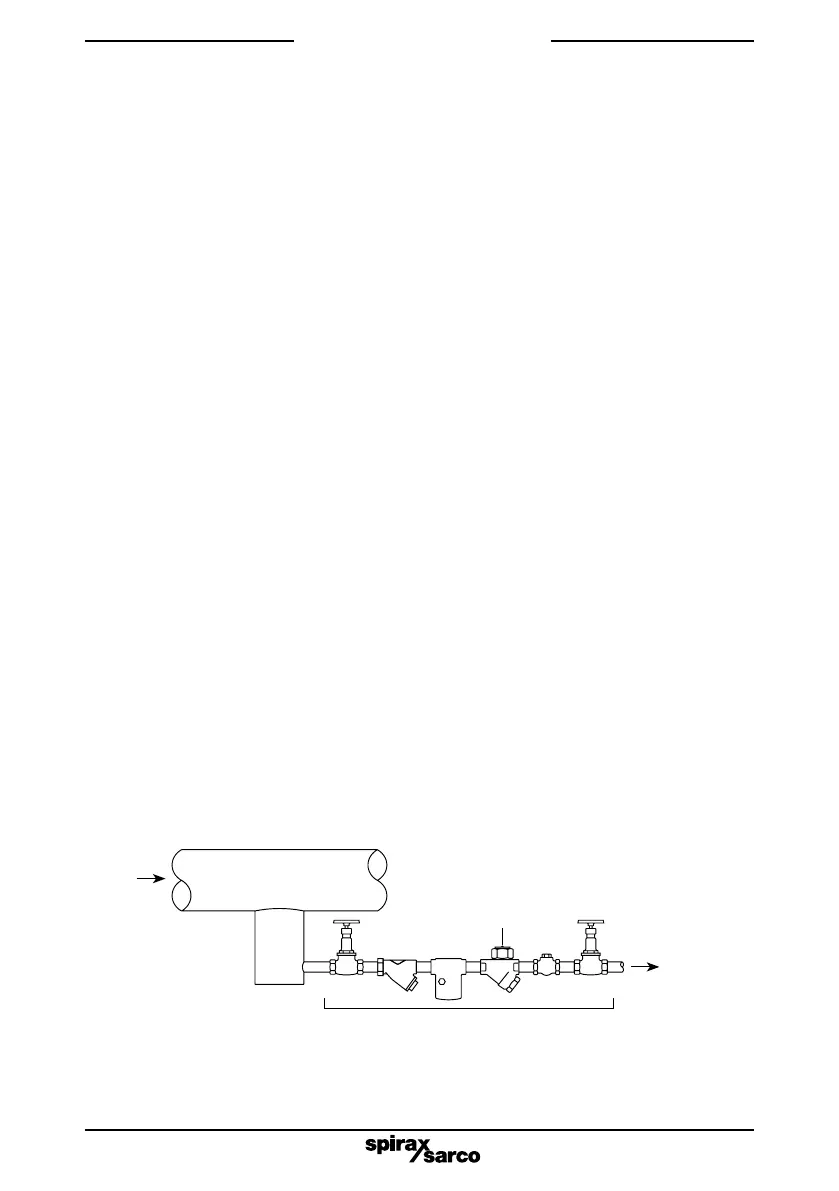

3.4 The trap should preferably be installed in the horizontal plane, with a small drop leg

preceding it. Suitable isolation valves must be installed to allow for safe maintenance

and trap replacement. Consideration should be given to a suitable method for

testing the correct operation of the trap. This may be a sight glass or a Spiratec

system. Sight glasses must be positioned a minimum of 1 m (3 ft) downstream of

any blast-action traps. Where the trap discharges into a closed return system, a

non-return valve should be fitted downstream to prevent return flow.

3.5 Isolation valves must be installed to allow for safe maintenance and trap replacement.

3.6 Always open isolation valves slowly until normal operating conditions are achieved -

this will avoid system shocks.

3.7 Check for leaks and correct operation.

Note: If the trap is to discharge to atmosphere ensure it is to a safe place, the discharging

fluid may be at a temperature of 100

°C (212°F).

TD42

Condensate

Steam

Steam trap set

Fig. 2 Typical application

Loading...

Loading...