HACK ATTACK™ BASEBALL PITCHING MACHINE

SPORTS ATTACK, LLC. • 800-717-4251 • sportsattack.com

11

COMPONENT REPLACEMENT

THROWING WHEEL REPLACEMENT

1. Turn the on/off switch “OFF” and unplug the power cord. For the bottom throwing

wheel, remove 6 bolts holding the wheel guard to the main casting.

2. Hold the wheel so that it cannot move. Turn the keyway retaining bolt counter-clockwise

using a box end wrench.

3. Remove the bolt and washers.

4. Work the wheel off of the motor shaft. Be sure to catch the key as it is freed from

the keyway.

5. Ball throwing wheels are machine balanced. Small holes in the side of the wheel are

applied at the factory and are normal. A slight wobble is normal.

Reassemble in reverse order.

a. Install wheel to motor shaft with key slots aligned.

b. Be sure the key is in place, and inserted so that it is flush with the boss at the

wheel center.

c. Be sure the washer and lock washer are installed in the right order, and that the

keyway retaining bolt is tightened.

d. Test the wheel by spinning it by hand and making sure that it spins freely without

wobble before turning the unit “ON”.

e. Be sure the wheel guard is properly and securely reinstalled.

MOTOR REPLACEMENT

1. Turn the on/off switch “OFF” and unplug the power cord.

2. Remove the throwing wheel (see above).

3. Remove four screws holding controller into main casting. Note the position of the motor

wires on the controller, then disconnect the wires. See Figure 10 on page 12.

4. Note the routing of the motor wires. Loosen any wire clamps.

5. Remove four bolts holding the motor to the main casting. See Figures 7 and 8 below.

Reassemble in reverse order.

Component Replacement

NOTE: On the bottom wheel, the

Front wheel guard (part 43 on

page 13) must be removed prior

to the removal of the motor or

ball-throwing wheel

Hold wheel while loosening bolts.

NOTE: Check bolts for tightness once a season. Tighten bolts securely, but do not over-tighten.

When replacing the motor, you will

see two sets of bolts:

2 -

1

/

4

” x 1

1

/

4

” coarse thread bolts

2 -

5

/

16

” x 1

1

/

2

” coarse thread bolts

The wrench or socket size needed

for the

1

/

4

” bolt is a

7

/

16

”.

The wrench or socket size needed

for the

5

/

16

” bolt is a

1

/

2

”.

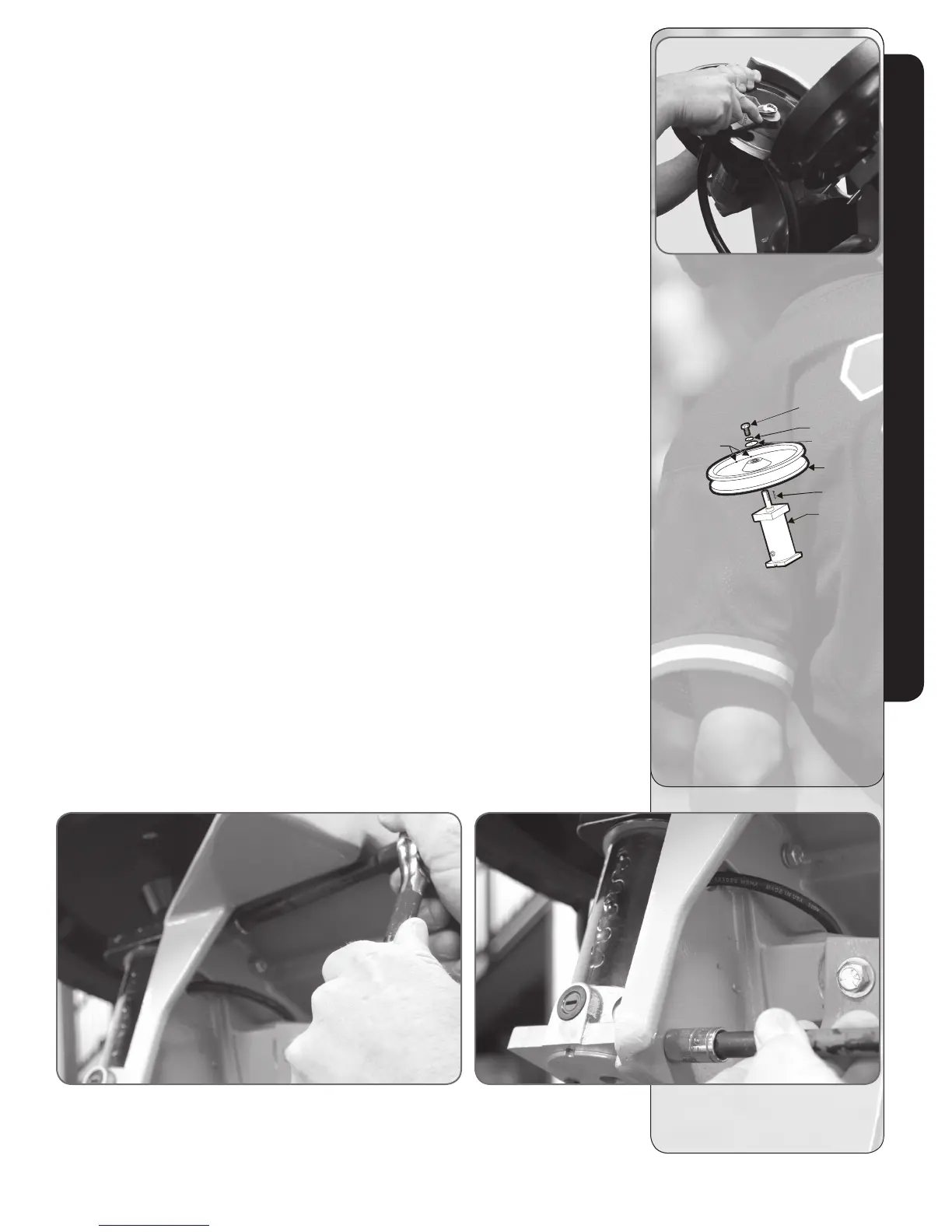

Figure 7 Shown using a 6” extension with

1

/

2

” socket. Figure 8 Shown using a 6” extension with

7

/

16

” socket.

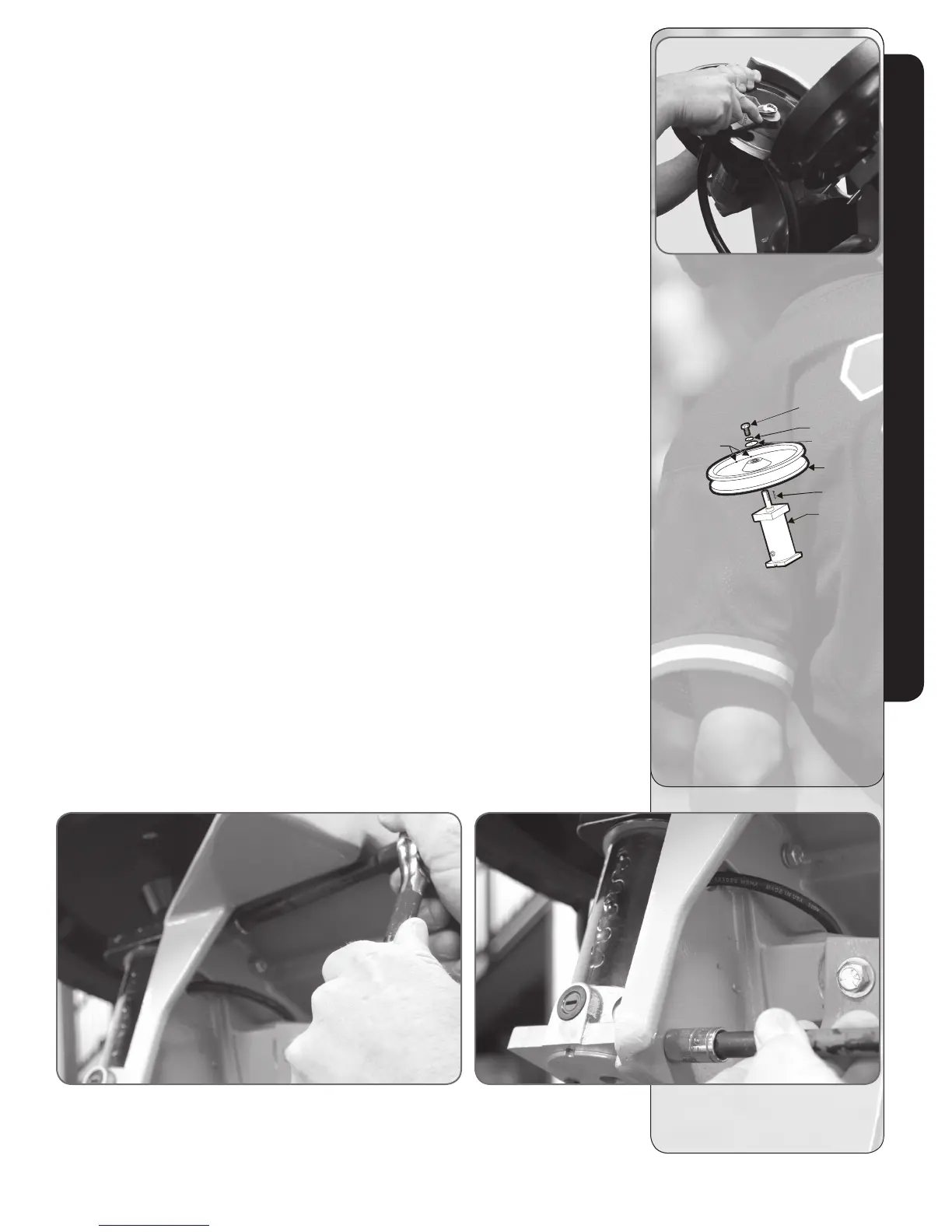

1/2” KEYWAY

RETAINING BOLT

LOCK WASHER

FLAT WASHER

KEY

MOTOR

THROWING

WHEEL

HOLES DRILLED

FOR BALANCE

Loading...

Loading...