Chapter 3: Programming

Chapter 3:2

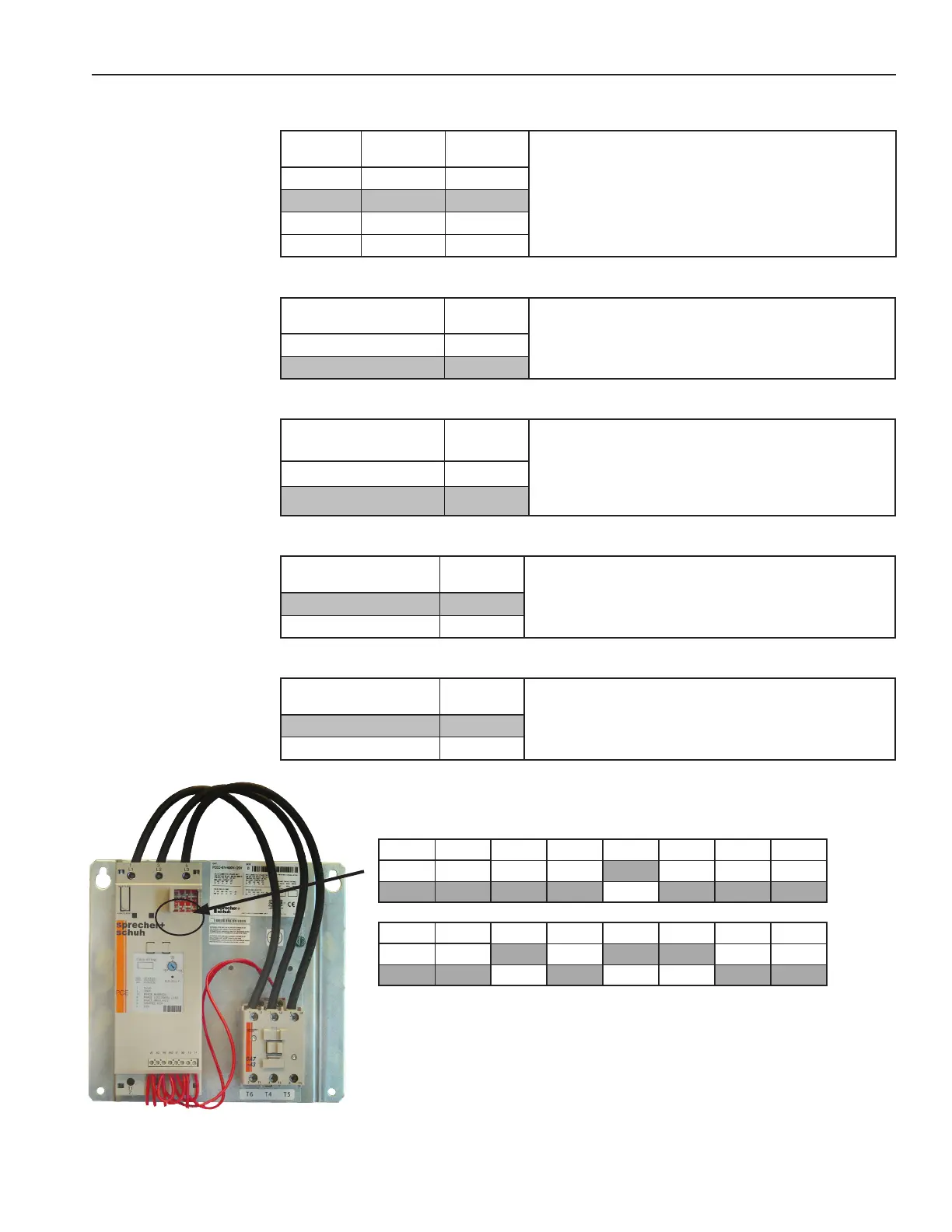

Table 11 - Overload Trip Class

Setting

DIP Switch

#11

DIP Switch

#12

The controller incorporates, as standard, electronic overload

protection. This motor overload protection is accomplished

electronically with the use of internal current transformers on

each of the three phases. The controller’s overload protection is

programmable, providing the user with flexibility.

OFF OFF OFF

10 ON OFF

15 OFF ON

20 ON ON

Table 12 - Overload Reset

Setting

DIP Switch

#13

In manual reset mode, the fault can only be reset by pushing the

‘push to reset’ button on the front of the controller. In auto reset

mode, the unit will automatically reset when unit determines the

motor has cooled to 75% of its thermal capacity.

Manual OFF

Auto ON

Table 13 - Aux#1 Setting

Setting

DIP Switch

#14

The operation defines the operation of the Auxiliary contacts.

Normal mode means that the contact will change state

immediately when a start/run command is given. Up-to-Speed

mode means that the contact will change state only when the

controller is in bypass. Aux#2 when added will operate opposite

of this programming.

Normal OFF

Up-to-Speed ON

Table 14 - Motor Connection Type

Setting

DIP Switch

#15

In DELTA connection mode, the device is designed to control a 6

or 12 lead motor. In LINE connection mode, the device is designed

to control a 3 or 9 lead motor.

Delta OFF

Line ON

Table 15 - Stop Delay

Setting

DIP Switch

#16

When the delay is programmed, the motor will continue to run for

the programmed period of time after the run command is removed

from the controller.

0.0 Sec OFF

0.75 Sec ON

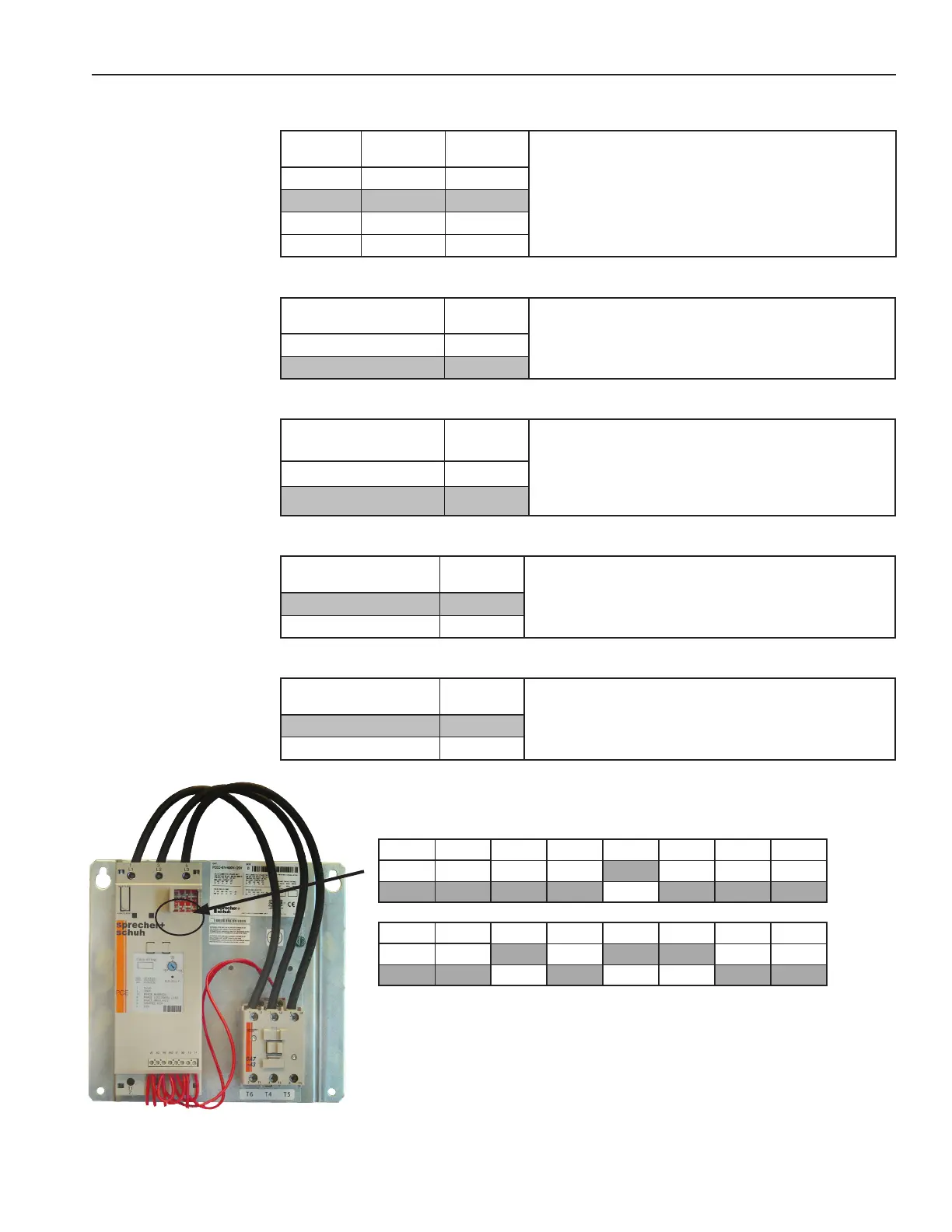

Factory DIP Switch Settings

1 2

3 4 5 6 7 8

ON ON

ON ON ON ON ON ON

OFF OFF OFF OFF OFF OFF OFF OFF

9 10

11 12 13 14 15 16

ON ON

ON ON ON ON ON ON

OFF OFF OFF OFF OFF OFF OFF OFF

Loading...

Loading...