30

8.0 Troubleshooting

WARNING - A POTENTIAL ELECTRICAL SHOCK

HAZARD EXISTS. Some of the troubleshooting

checks may require gaining access to the dryer’s

electrical enclosure(s) while the power supply is

energized and should be performed by a qualied

electrical technician.

WARNING - Before performing any electrical or

mechanical repairs or maintenance, or removing

or disassembling any component, be sure to de-

energize and depressurize the dryer.

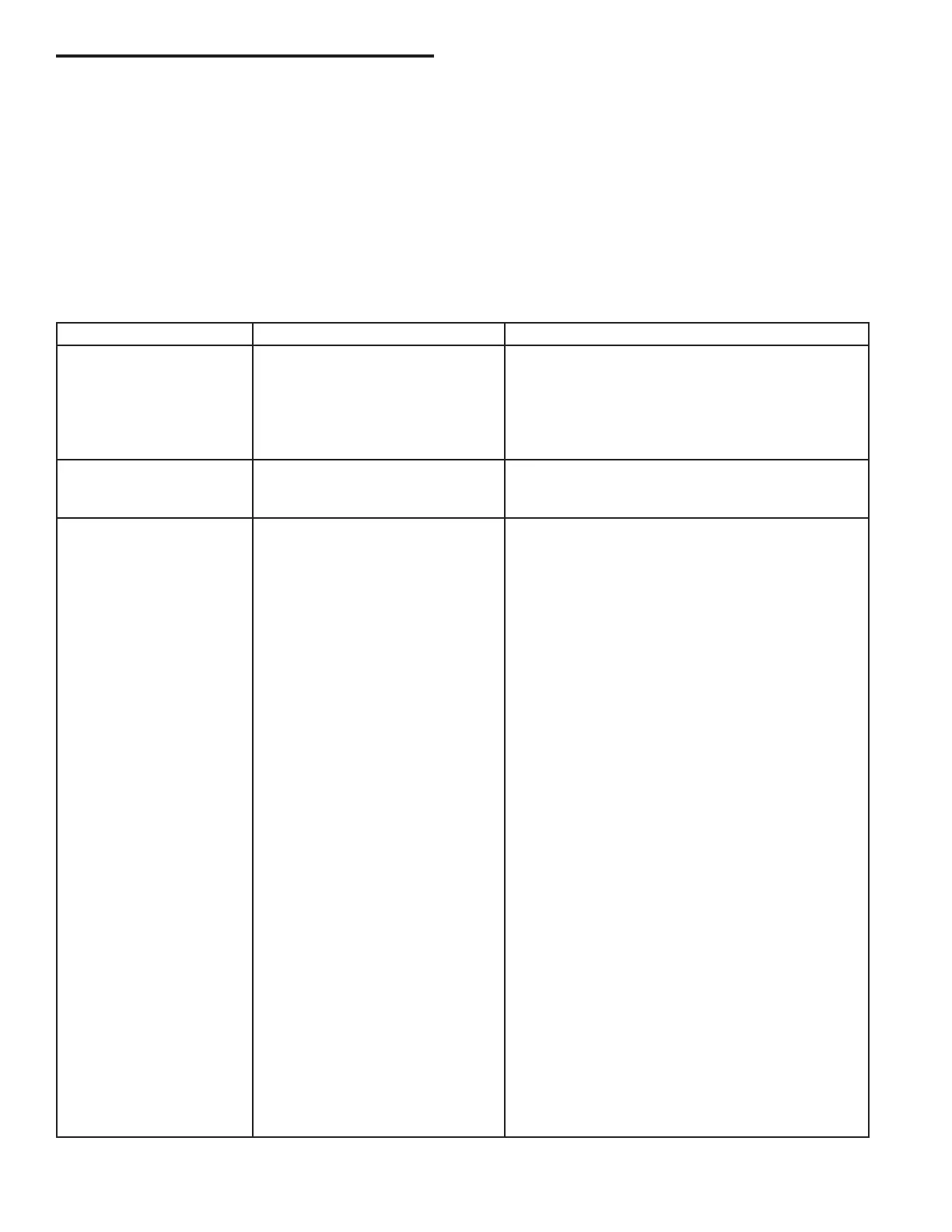

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Indicator lights not illuminated 1. No power to unit.

2. Loss of power supply to (or at) dryer’s

electrical disconnect switch or breaker.

(customer supplied)

3. Blown fuse.

4. Board malfunction.

1. Check voltage at terminal board.

2. Check disconnect switch or breaker closed. If tripped

breaker or blown fuse is noted, investigate and Remedy

cause.

3. Replace fuse.

4. Replace board.

Excessive pressure drop in dryer 1. Inlet/Outlet screens on desiccant tow-

ers are dirty

2. Excessive ow rate

1. Clean screens; follow desiccant removal instructions in the

Maintenance section.

2. Check ow rate of inlet air. Reduce to design ow rate.

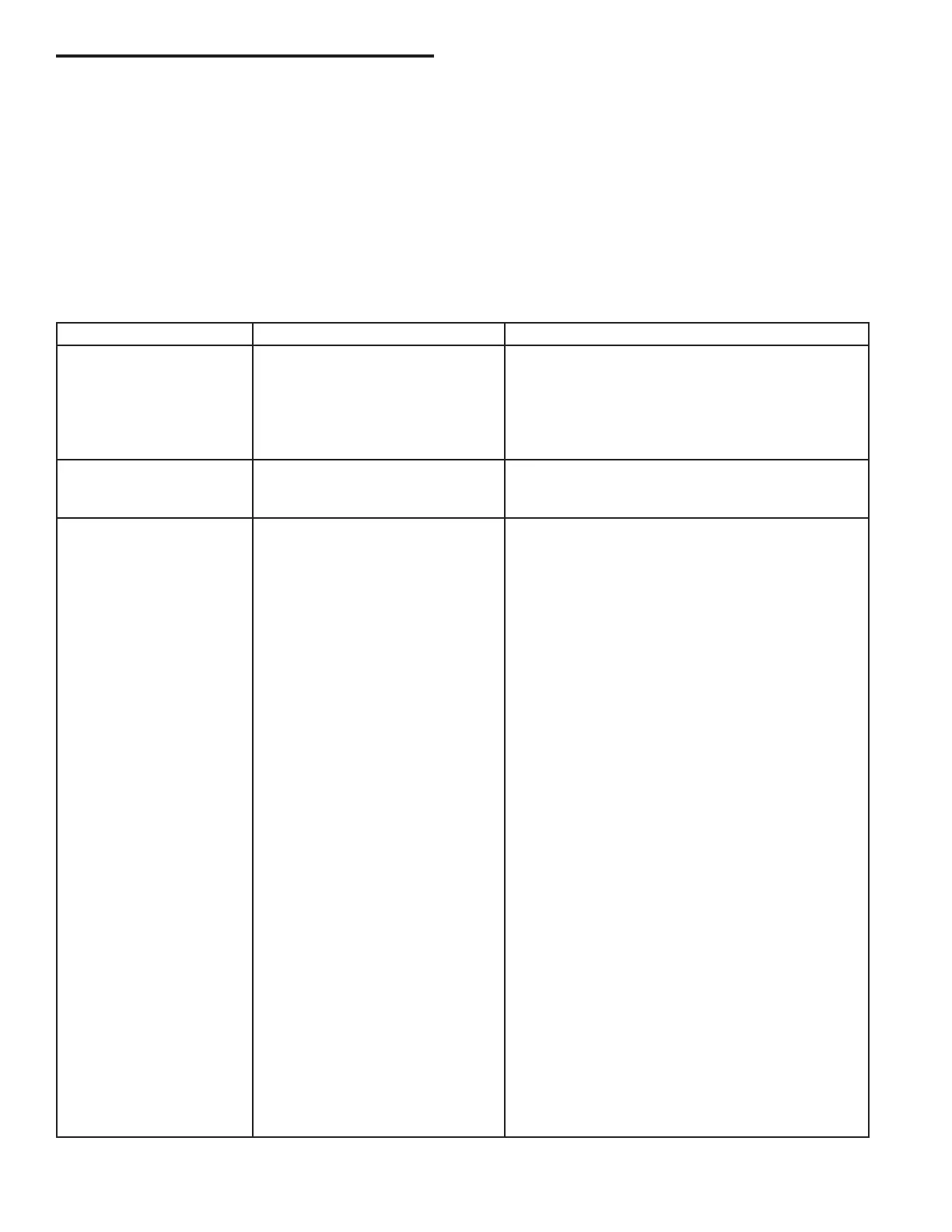

Low Pressure Alarm

Left Tower or Right Tower

Drying

1. Loss of dryer air supply.

2. Excessive air demand.

3. Faulty drying tower pressure switch

4. Drying tower Inlet Valve failed to open

5. Drying tower Purge Exhaust Valve

failed to close.

6. Drying tower Depressurization Valve

failed to close

7. Regenerating tower Outlet Check

Valve failed to close

8. Drying tower Purge Check Valve leak-

ing

1. Check compressor supplying dryer.

2. Check equipment downstream of dryer.

3. Check pressure switch operation using tower pressure

gauge for comparison. Replace switch if defective.

4a. Check for loss of pilot air - ensure manual drain valve on

bottom of pilot air lter is fully closed, ensure pilot air lter

cartridge is not clogged, ensure pilot air shut-off valve is

open

4b. Check for inlet pilot air solenoid valve failure. Check valve

operation. Repair or replace as necessary.

4c. Check for drying tower Inlet Valve failure - examine valve

and actuator for damage. Repair or replace as necessary.

5a. Check for air ow out of drying tower Purge Valve or ex-

haust piping indicating valve is not completely closed.

5b. Check for loss of pilot air - ensure manual drain valve on

bottom of pilot air lter is fully closed, ensure pilot air lter

cartridge is not clogged, ensure pilot air shut-off valve is

open

5c. Check for purge pilot air solenoid valve failure. Check valve

operation. Repair or replace as necessary.

5d. Check for drying tower Purge Exhaust Valve failure - exam-

ine valve and actuator for damage. Repair or replace as

necessary.

6. Check for air ow out of drying tower Depressurization

Mufer indicating valve is not completely closed. Repair or

replace as necessary.

7. Indicated by excessive ow out of regenerating tower

Purge Valve. Examine valve internals. Repair or replace

as necessary.

8. Indicated by excessive ow out of regenerating tower Purge

Valve or reverse air ow through heater and blower, i.e., out

of the blower intake lter, examine valve internals. Repair

or replace as necessary.

CAUTION: Air owing backwards through heater and

blower may be very hot.

Loading...

Loading...