32

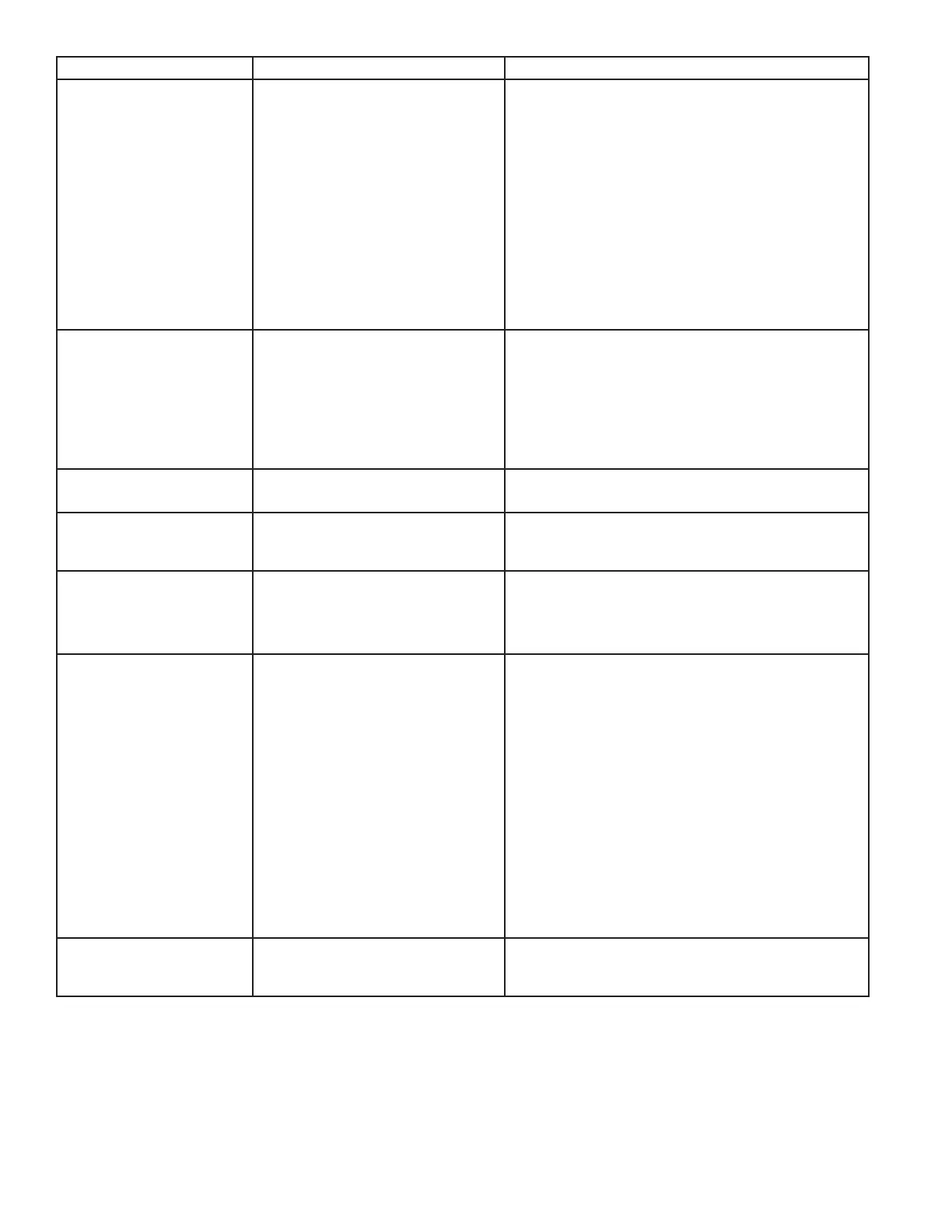

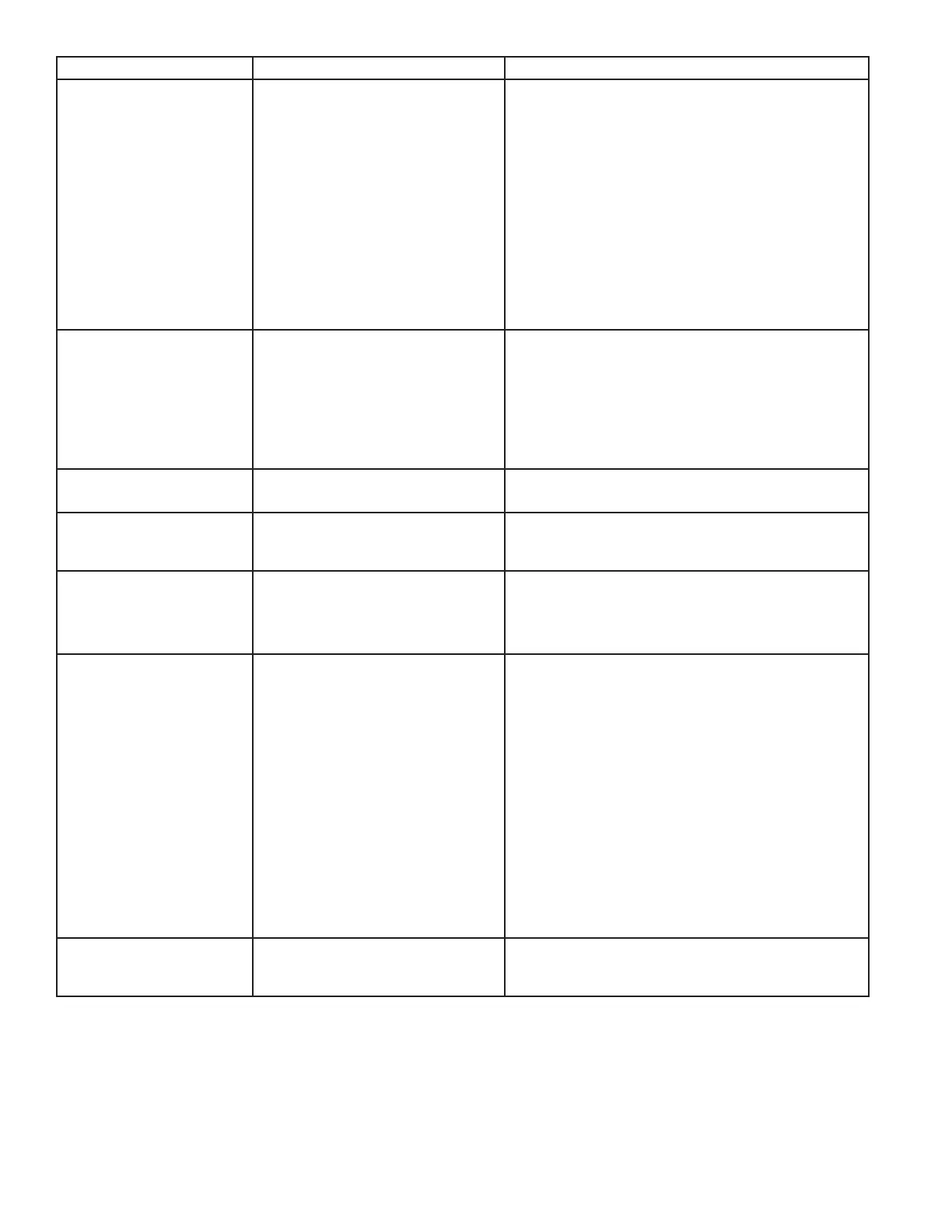

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Outlet Dew Point Alarm

Left Tower or Right Tower

1. Inlet air ow higher than the sizing

condition.

2. Liquids entering the dryer inlet.

3. Inlet air temperature higher than the

sizing condition.

4. Desiccant dusting.

5. Contaminated desiccant (e.g. with oil).

6. Heater temperature set too low.

7. Heating malfunction due to heater

failure or heater contactor failure.

1. Reduce inlet ow to sizing condition.

2. Check the inlet air line for liquids. Inspect prelter and

drain valve. Clean, repair or replace automatic drain valve.

3. Check the compressor aftercooler and cooling system.

Reduce inlet air temperature to sizing condition.

4. Check air pressure, airow and airow surges and correct

as necessary. Replace desiccant.

5. Check prelter and automatic drain valve. Replace prelter

element. Clean, repair or replace drain valve as necessary.

Consult factory concerning need for desiccant replacement.

6. Adjust controller set point.

7. Replace heater or heater contactor.

High Humidity Alarm

Left Tower or Right Tower

1. Desiccant bed overloaded.

2. Dew point sensor or monitor damaged

or defective.

3. Loss of desiccant drying capacity

1. Check inlet air ow rate, temperature and pressure. Higher

than design ow, and temperature, and lower than design

pressure will result in overloading of the dryer.

2. Examine sensor for physical damage and check monitor/

sensor operation. Replace sensor or monitor as necessary.

3. Inlet air improperly ltered causing desiccant contamination

- examine lter elements and drains. Repair or replace as

necessary. Useful life of desiccant has been exceeded.

Heater Over-Temperature

Alarm

1. Insufcient purge gas ow.

2. Temperature sensor failure.

1. Check for purge blockage, temperature sensor failure, etc.

2. Repair and replace as required.

Heater Low-Temperature

Alarm

1. Heating malfunction due to heater

failure or heater contactor failure.

2. Temperature sensor failure.

1. Replace heater or heater contactor.

2. Repair and replace as required.

Energy Management Under-

Range Alarm

or

Energy Management Over-

Range Alarm

1. Energy Management sensor failure. 1. Check circuit for continuity. Repair or replace as neces-

sary.

Blower Motor Overload Alarm 1. Restricted or blocked purge air ow.

2. Line failure

1a. Dirty intake lter on blower - examine lter element and

clean or replace.

1b. Regenerating tower purge exhaust valve failed to open -

1) Check for loss of pilot air - ensure manual drain valve on

bottom of pilot air lter is fully closed, ensure pilot air lter

cartridge is not clogged, ensure pilot air shut-off valve is

open.

2) Check for purge pilot air solenoid valve failure. Check valve

operation. Repair or replace as necessary.

3) Check for regenerating tower Purge Exhaust Valve failure -

examine valve and actuator for damage. Repair or replace

as necessary.

1c. Purge exhaust piping obstructed - ensure piping is free of

obstructions.

1d. Regenerating tower purge check valve failed to open - ex-

amine valve internals. Repair or replace as necessary.

2. Check voltages and currents in the motor circuit.

Heater High Inlet Temperature

(models 3200, 3600, & 4300

only)

1. On-line tower purge check valve is

leaking.

2. Temperature sensor failure.

1. Examine valve internals. Repair or replace as required.

2. Repair and replace as required.

Loading...

Loading...