Waukesha Cherry-Burrell

®

Brand W60/W80 Valves Maintenance

02/2020 95-03022 Page 39

Servicing Actuators:

U-cups, O-rings and

Bearings

Shut off the air and disconnect the air supply line to the actuator.

Disconnect/lockout the electrical power to the valve.

Valves with Control Module

For control top information, please refer to publication 95-03083.

For additional product information, please see our website at

spxflow.com/en/waukesha-cherry-burrell/resources/product-

literature/.

O-ring and Bearing Replacement: 4”, 5”, and 6"

Actuator

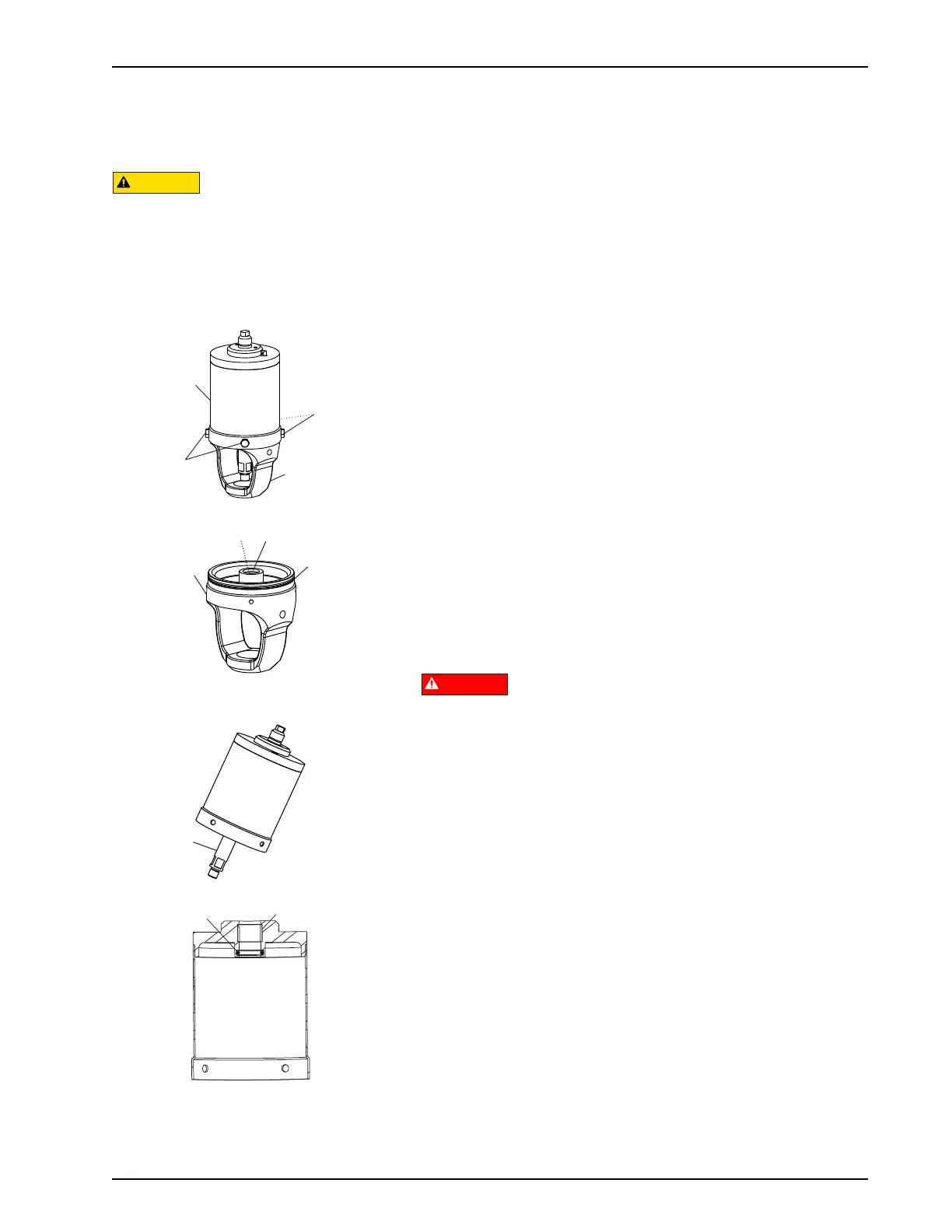

1. Remove the cap screws (Figure 32, item 9) and pull the yoke

(item 12) from the actuator cylinder (item 4).

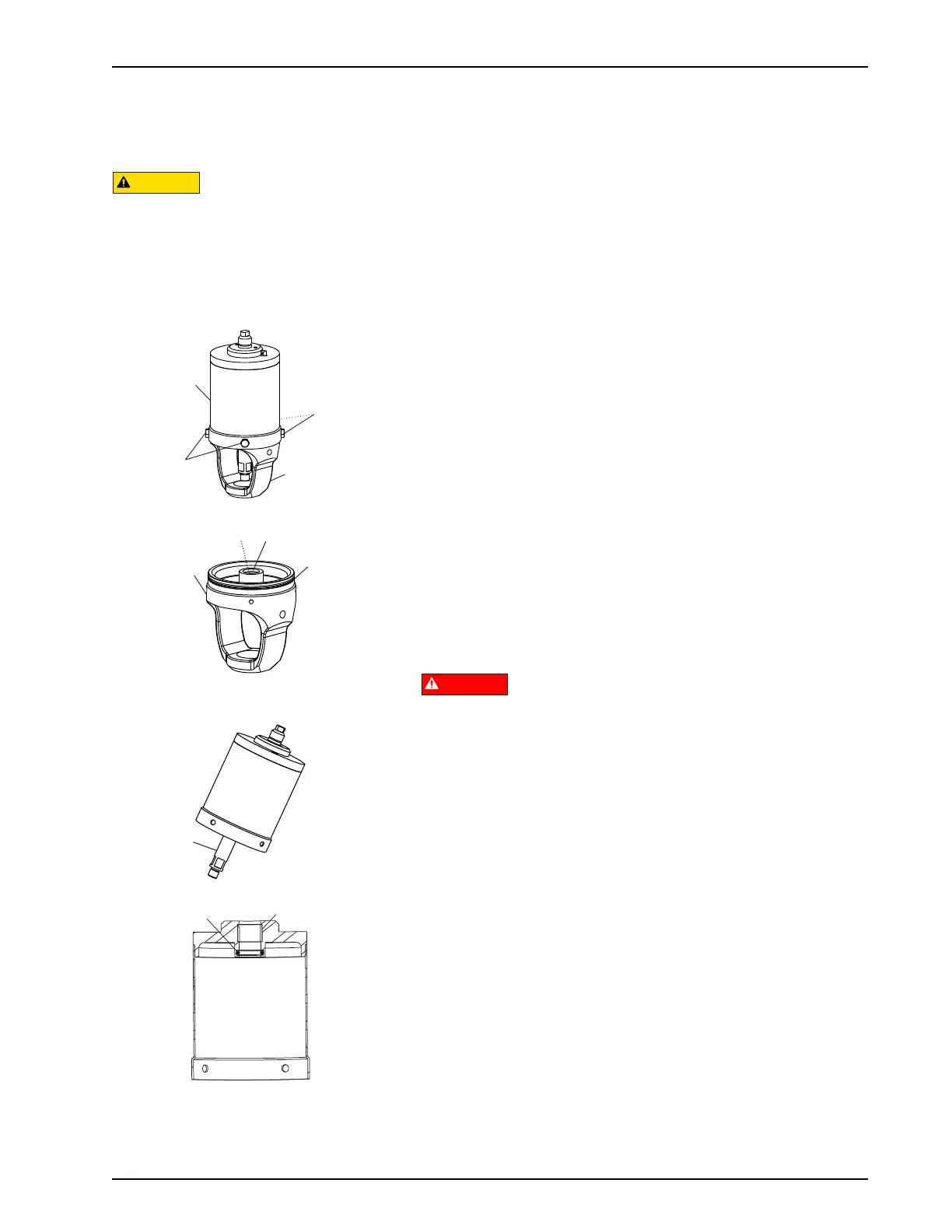

2. Remove the yoke (Figure 33, item 4). Inspect the lower stem

O-ring (item 6) and cylinder O-ring seals (item 7).

3. Remove the worn O-ring seals. Coat the new O-ring seals

with Dow Corning

®

#7 Silicone Lubricant or equivalent, and

replace them.

4. Remove the PTFE guide bearing (Figure 33, item 5) by

placing a screwdriver behind the bearing to pry it away from

the wall of the yoke. Use needle-nose pliers to grip and

remove the bearing.

5. Pull the lower stem (Figure 34, item 3) to remove the caged

spring assembly from the actuator cylinder.

Do not use air to remove the caged spring assembly.

6. Remove and inspect the upper stem O-ring (Figure 35, item

6) in the top of the actuator cylinder.

7. Remove the worn O-ring seals. Coat the new O-ring seals

with Dow Corning

®

#7 Silicone Lubricant or equivalent, and

replace them.

8. Inspect and replace the PTFE guide bearing (Figure 35, item

5) in the actuator cylinder as needed.

Although WCB fully-maintainable

actuators are designed with a contained

spring for safety, always use caution

when handling any piston/spring

assembly as any compressed coil spring

can be extremely dangerous.

Figure 32: Remove Yoke

Figure 33: Remove Yoke O-ring and Guide

Bearing

Figure 34: Pull Lower Stem

Figure 35: Remove O-ring and Bearing

Loading...

Loading...