31

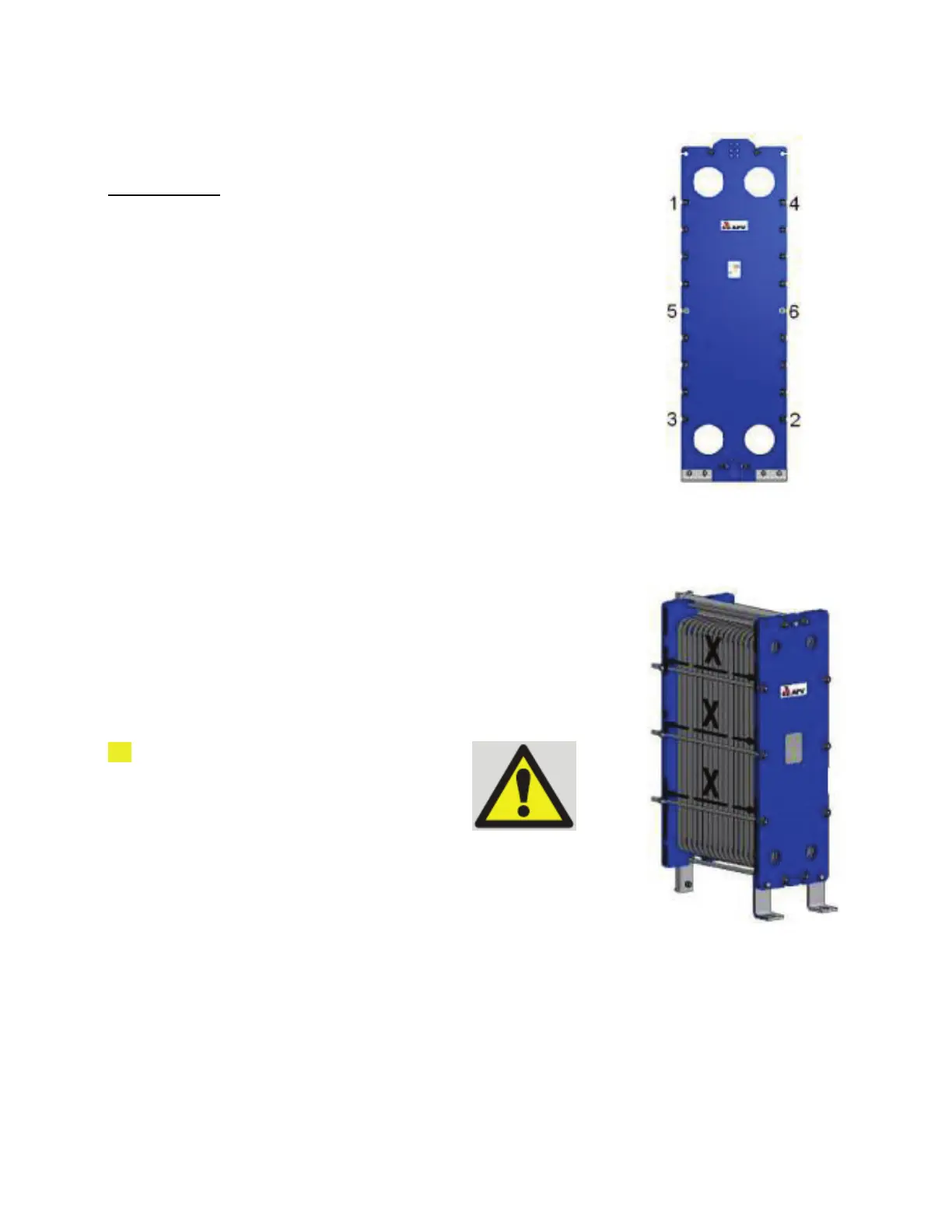

For large units

(Distance between bars 1 and 3 >1200 mm)

Compress plate pack in small increments, always

moving diagonally from one tie bar to the next.

Reach final dimension X + 10% by tightening

bars 1 to 6 in the order given, in increments of

25 mm or less. Then add all left side and right

side bars. Tighten all bars to dimension X+5% in

increment of 6 mm or less. Then add the 2 top

and 2 bottom bars and compress in 3 mm

increments to X.

By using hydraulic compression tools 2, 4 or

6 bolts can be compressed at the same time.

The order of bolts and increments must be

the same as above.

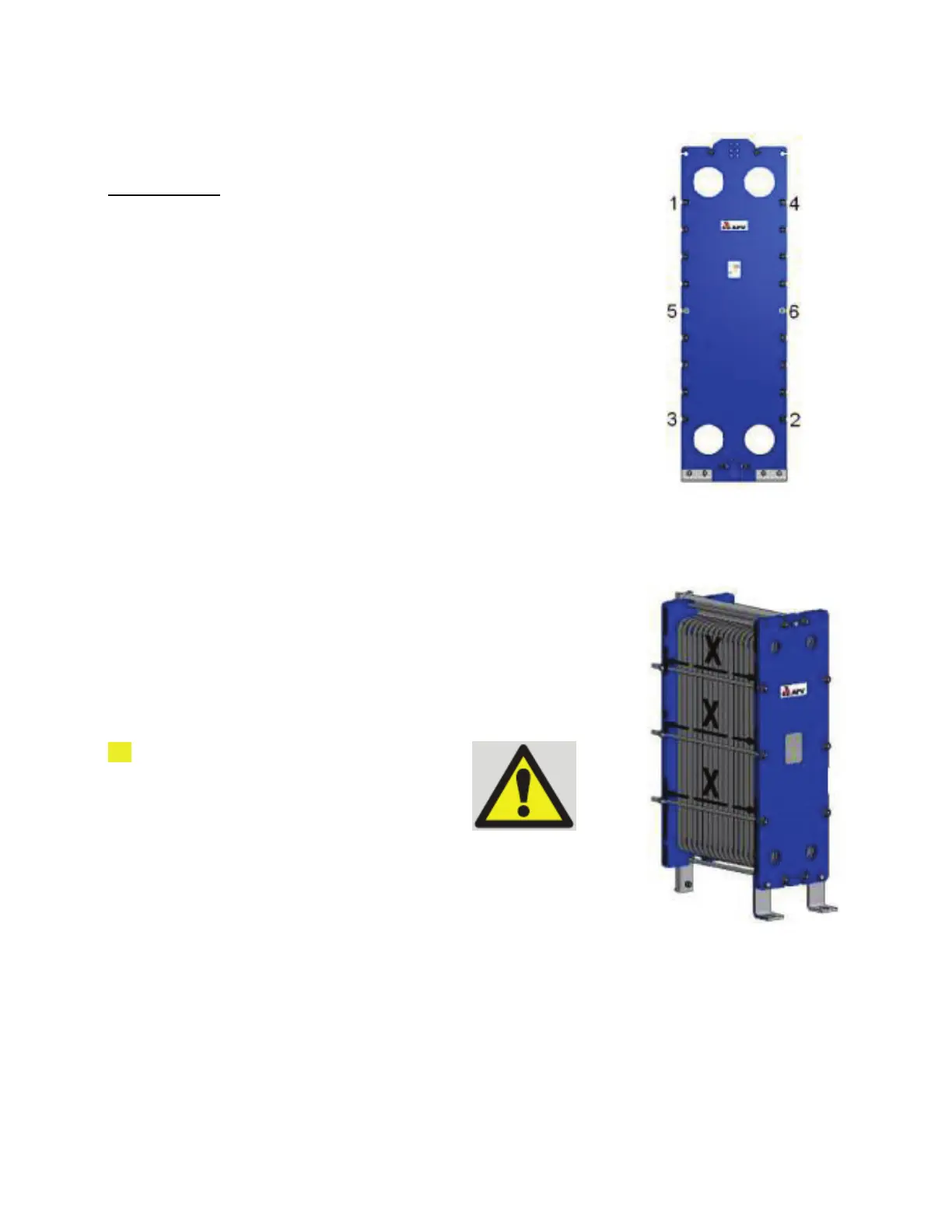

It's important that head and follower are kept

parallel during the compression work.

In this regard, compression must be

measured at the top, middle, and bottom

sides. Measurements are to be taken close

to the tie bars.

Ì! Always tighten to full plate to plate

contact, demonstrated by sufficient force and

within the dimensions permitted. On the

nameplate or the assembly drawing, you will

find the minimum and maximum compressed

dimension of the plate pack.

In multi section machines, differences in

pressures through the sections can set up a

concertina effect where higher pressure

sections open up by a few hundredths of

millimetres per plate and lower pressure

sections close down. Opening up of higher

pressure sections can cause leakage of that

section. The robustness of the PHE is also

Top

Bottom

Right side

Left side

Loading...

Loading...