AC S.A. All rights reserved. Any unauthorized copying, reproduction, publishing, dissemination, disclosing or other use of information presented herein, in whole or as part, particularly photographs,

drawings, trademarks, etc., may lead to prosecution or civil proceedings.

6

turbocharger, as exhaust gas pressure variations upstream the turbocharger may cause a false reading.

The sleeve should be placed at the maximum available distance from the cylinder head, and in

turbocharged engines - from the turbocharger (50 cm minimum). Otherwise, the oxygen sensor can

overheat and fail!

When the probe is installed too close to the cylinder head it may overheat and fail!

A gap of at least 50 cm should be kept.

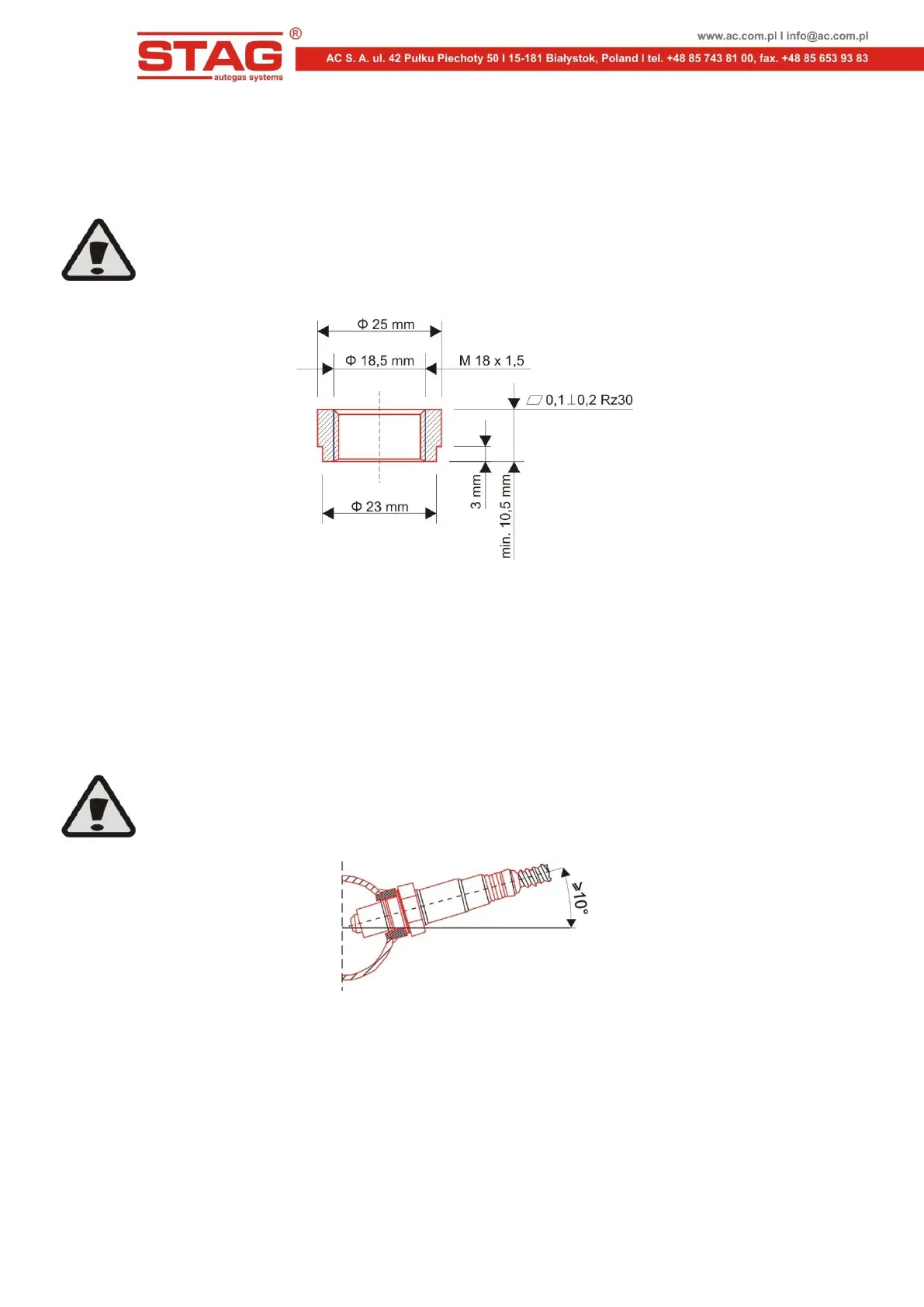

Figure 3. The recommended dimensions of the oxygen sensor mounting sleeve.

The oxygen sensor should be put in the exhaust gas stream in such a way so that atmospheric sensor

does not affect the results of measurement (the exhaust system between the engine and measuring point

should be tight).

The oxygen sensor mounting sleeve should be mounted in the upper part of the exhaust manifold

(between 10 and 2 o'clock), as shown in Figure 3.

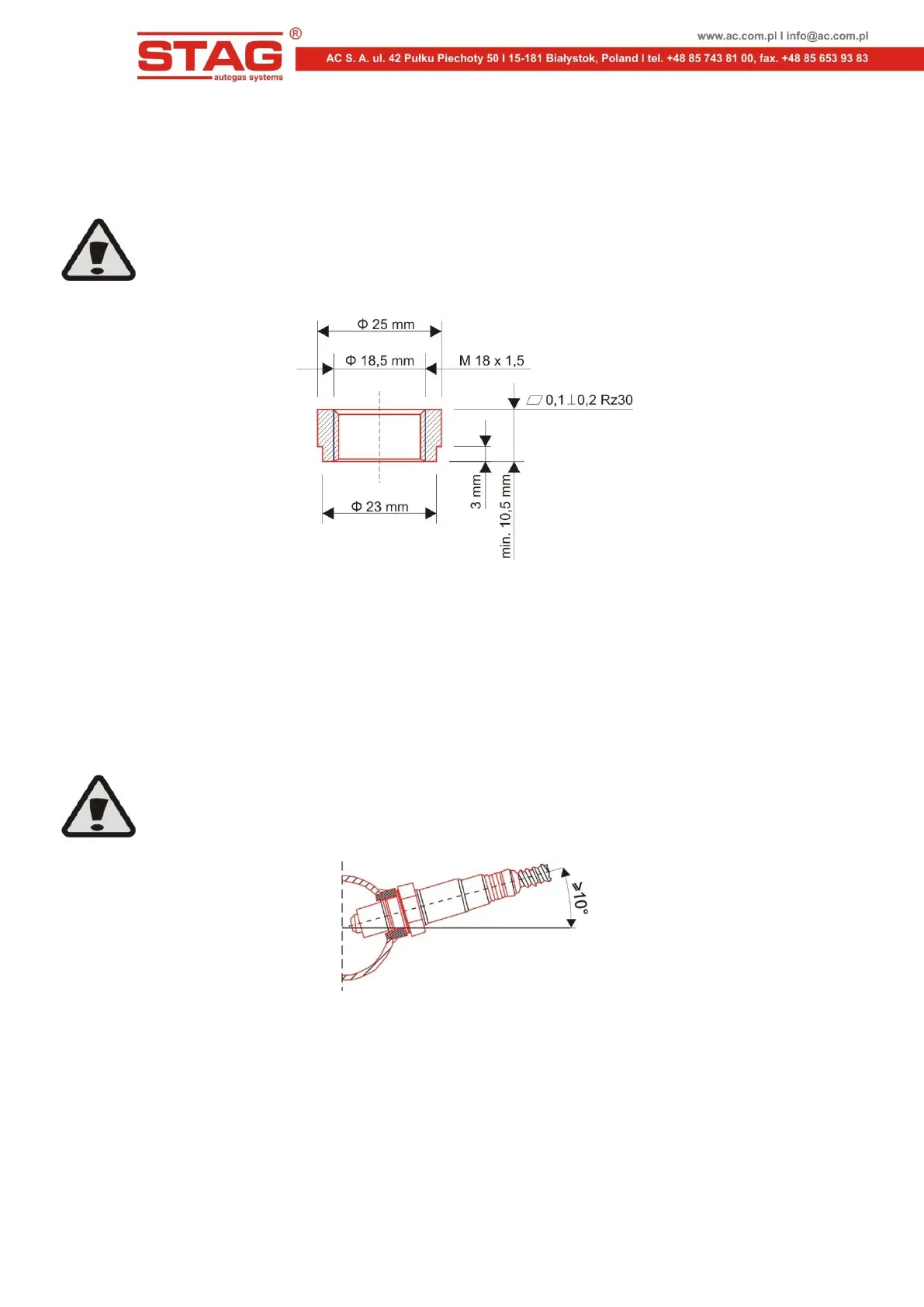

When the probe is mounted with the harness faced downward the probe measuring element

will be rapidly damaged by condensed water vapour!

Figure 4. The minimum mounting angle of the oxygen sensor installed in the exhaust system.

4.3 Mounting by using the exhaust gas guiding pipe

If measurements are to be made on many vehicles, it is suggested to make an exhaust gas guiding pipe

to facilitate quick mounting and dismounting of the kit. Shown below the exhaust guide allows the study of

the composition of the mixture, regardless of the circumstances under which the measurement is

performed.

Loading...

Loading...