ASSEMBLY INSTRUCTIONS

16

18

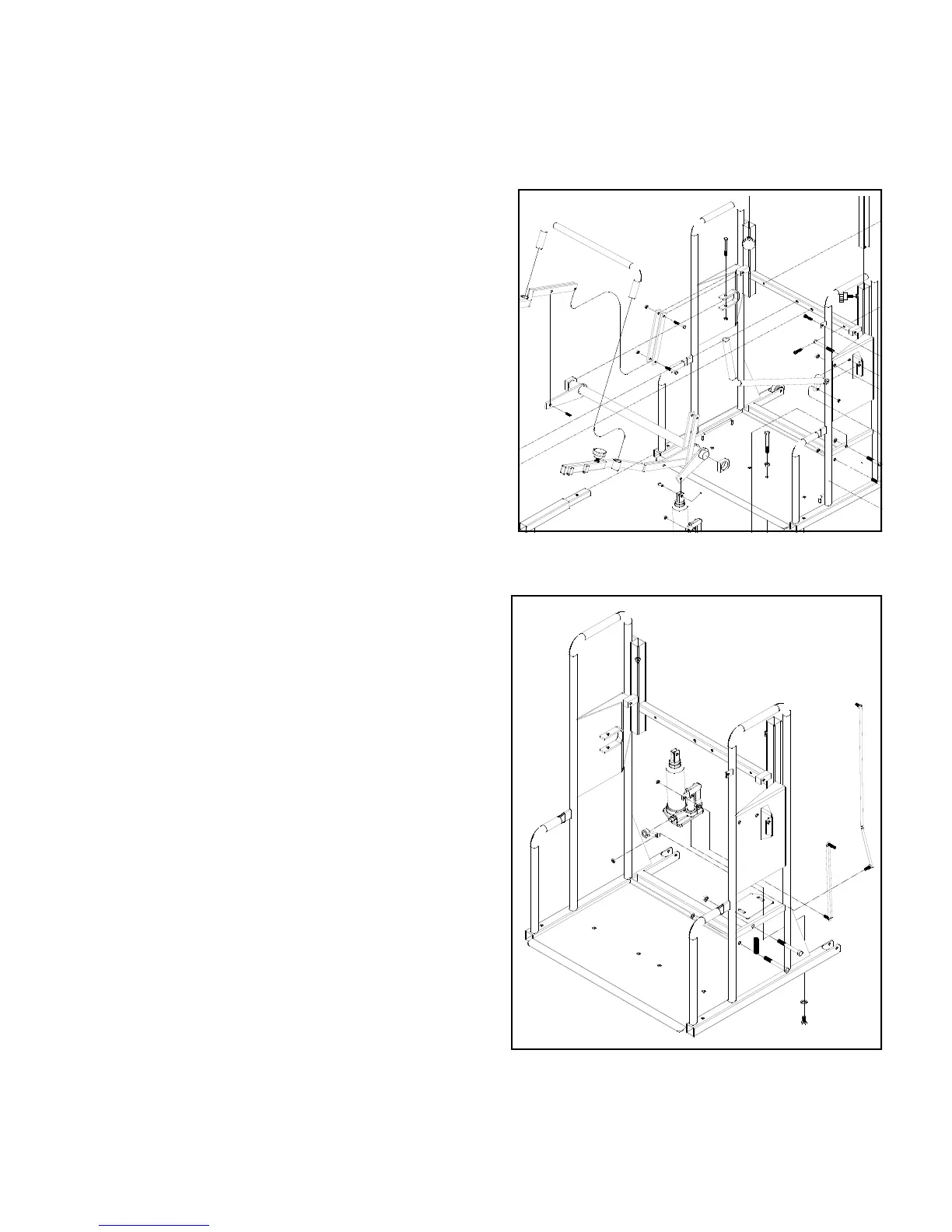

IMAGE #2

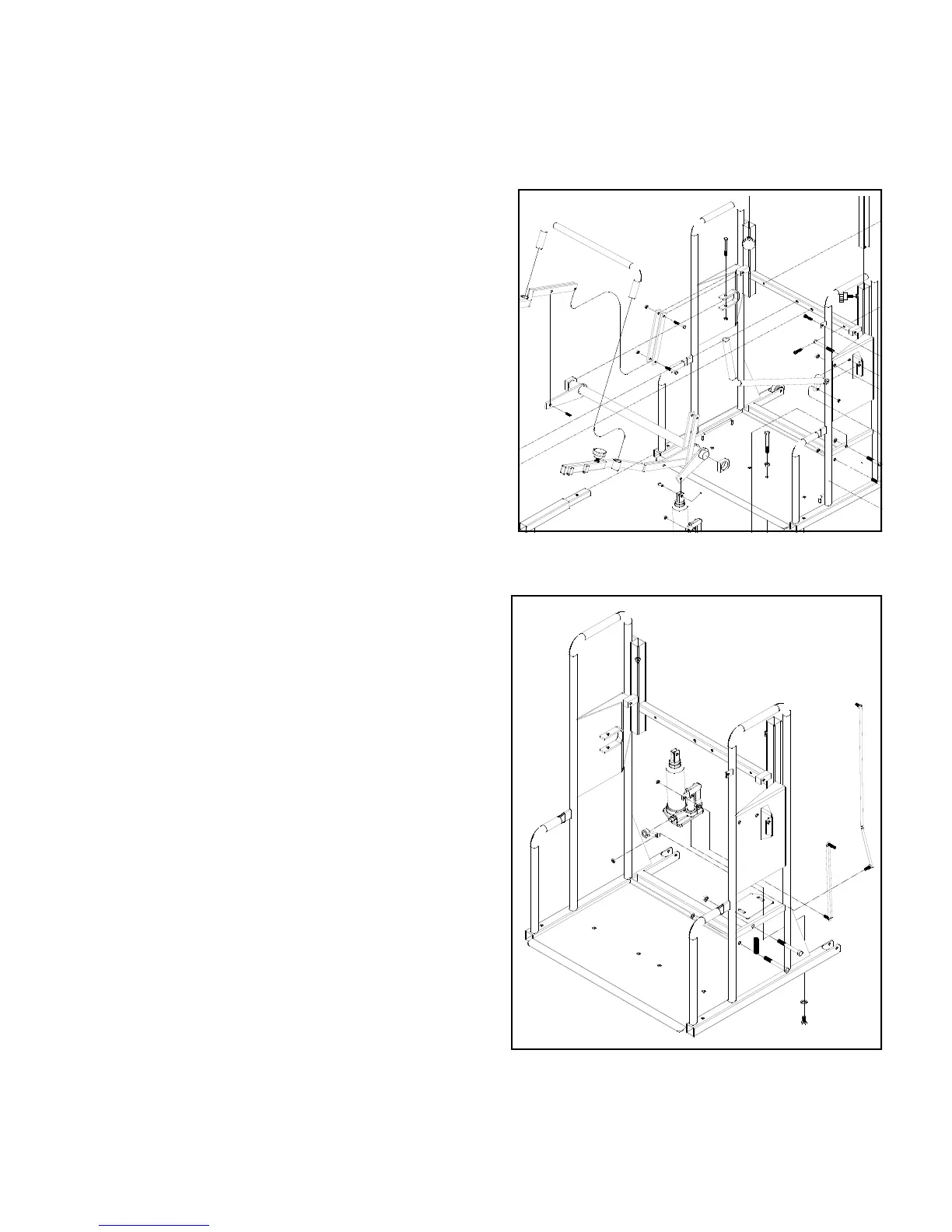

IMAGE #1

2

3

4

5

6

9

7

38

NOTE: Refer To Main Diagram on Pg. #8 for vis-

ual unless otherwise specified.

1. Insert the two mainframe support legs (#14) into bottom

rear mainframe (#1) tubes. Secure using 5/16” x 1-1/2” Roll

Pin.

2. Attach the two wheels (#15) to the front of the mainframe

bottom tubes using 1/4” x 1-1/2” bolt w/ locknut

3. Insert the drive bar (#2) with the nylon bushings (#3) on

each end into mainframe. Secure in the u-mounts located in-

side the mainframe using 5/16“ x 2-1/2“ bolt w/ locknut. See

image #1 at right.

4. Attach the linkage plates (#4) to the block mounts on the

mainframe using 1/4” x 1-3/4” bolt w/ locknut.

5. Attach the right and left lift arms (#5 & #6) to the drive bar

arms. (drive bar arms go between the lift arm plates) Secure

using 5/16“ x 3/4“ roll pin. The bottom of the lift arms attach

at the bottom of the drive bar and in between the linkage

plates on each side with 1/4“ x 1-3/4“ bolt w/ locknut. Slide

the adjustable lift arm hooks (#7 & #8) onto the lift arms and

secure using the threaded knobs (#10). NOTE: Desired posi-

tion can be determined at any time.

6. Insert the stabiliser tube (#9) into the lift arm tubes on each

side. Secure with self-tapping screws through stabilizer tube

and lift arm tube.

7. Attach the jack mount bracket (#18) to the mainframe.

Bracket mounts at the lower right or left (depending on model

ordered) side of mainframe, inside of frame upright. See im-

age #2 at right. Secure using 3/8“ x

1-1/2“ bolt w/ locknut.

8. Mount the hydraulic jack (#16) to the jack mount bracket

using two 5/16“ x 1/2“ bolt w/ flatwasher. NOTE: Jack

mounts on with the pump linkage to the outside. See image

#2 at right.

9. Attach the jack clevis to the drive bar right outside arm us-

ing pin (#38) and cotter pin. see image #1 at right.

10. IMPORTANT: Assemble the knee pad mount (#11),

the two slide plates (#12), and the knee pad (#13) simultane-

ously. Place knee pad mount (#11) between the slide plates

(#12). Center this assembly and attach to the knee pad (#13)

using 10-24 x 3/4” machine screws, two flatwashers under the

slides (#12) to provide clearance for the knee pad mount

(#11) slides.

11. Attach the whole knee pad assembly to the mainframe

front cross tube. Secure using two 10-24 x 1/2“ machine

screws. NOTE: The channel on the knee pad mount fits over

the drive bar.

1

Page 9

Loading...

Loading...