BR67 User Manual | 11

What is the BR67 Hydraulic Breaker?

BR67 is a hydraulic breaker for use in the 70-90 lbs. weight class. It is highly

productive in utility construction, street maintenance, repair of water and

gas mains, and general contracting jobs. BR67 requires an external hydraulic

power source capable of supplying 7-9 GPM.

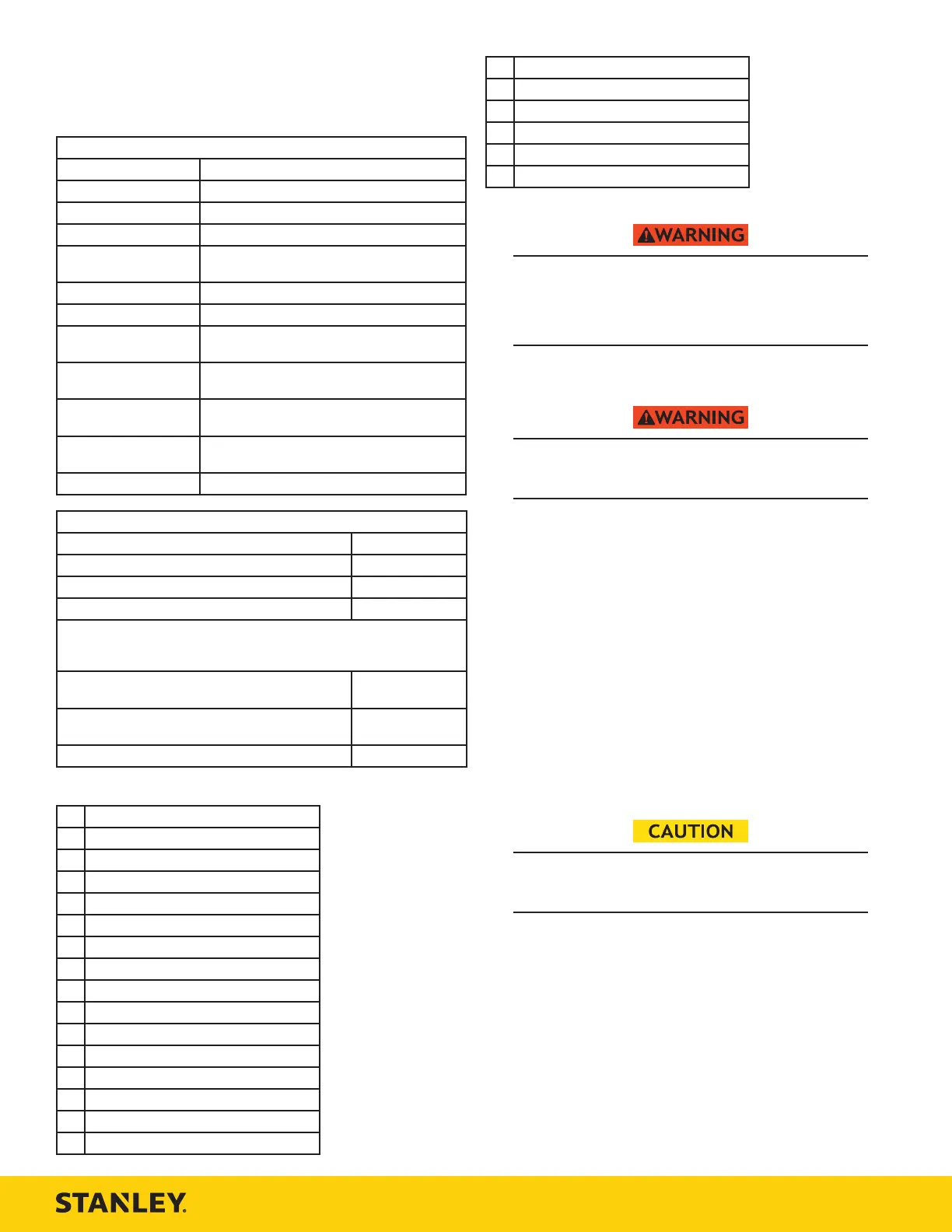

Specifications

Pressure 1500-2500 PSI (103-172 BAR)

Flow 7-9 GPM (26-34 LPM)

Max. Pressure 2500 PSI (172 BAR)

Max. Relief Pressure 2150 PSI (148 BAR)

Recommended Back

Pressure

250 PSI (17 BAR) or less - Can be used with

higher back pressures with reduced seal life.

Couplers 3/8 Inch Male Pipe Hose Ends

Port Size -8 SAE O-ring

Tool Weight T-Handle: 67 Lbs (30 Kg)

Anti-Vibration: 75 Lbs (34 Kg)

Tool Length T-Handle: 29 Inches (74 cm)

Anti-Vibration: 27 Inches (69 cm)

Width (at handles) T-Handle: 16 Inches (41 cm)

Anti-Vibration: 18 Inches (46 cm)

Max. Hydraulic Oil

Temp.

140°F (60°C)

HTMA/EHTMA Category Type II, Category D

Sound & Vibration Declaration

Measured A-Weighted sound power level 103 dBA

Uncertainty 1.7 dBA

Measured A-Weighted Sound Pressure 99 dBA

Uncertainty 3 dBA

Values determined according to noise test code given in ISO 15744, using

the basic standard ISO3744. Test conducted by independent notified body

to comply with 2000/14/EC:2005.

Measured Vibration Emission Value: 3-Axis (Trigger

Handle)

7.7 m/sec ²

Measured Vibration Emission Value: 3-Axis (Non-

Trigger Handle)

7.2 m/sec ²

Uncertainty 1.46 m/sec ²

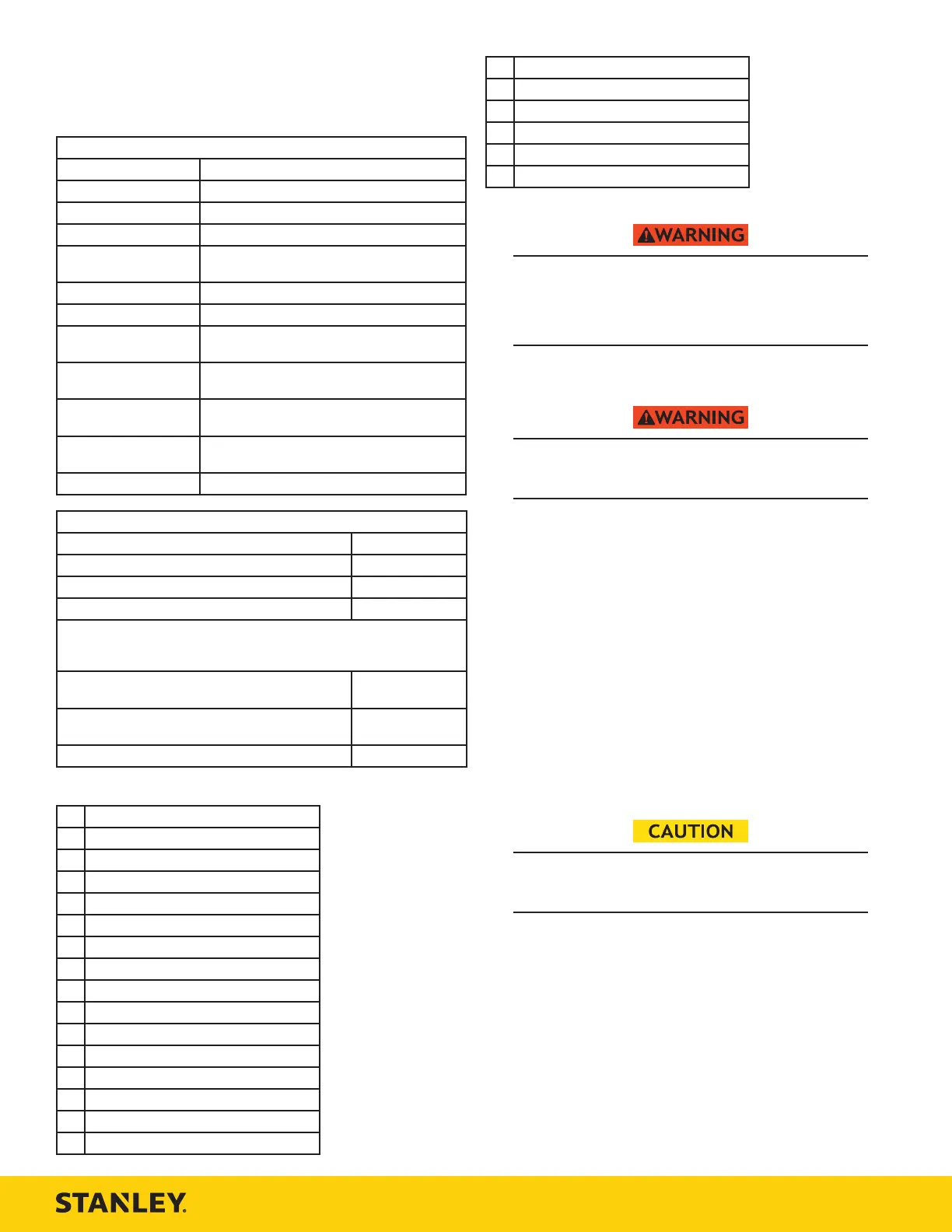

Parts of a BR67 - Detail A

1

Accumulator Valve Cap

2

Trigger

3

Handle

4

Hydraulic Supply Ports

5

Accumulator

6

STANLEY Logo Decal

7

Breaker Foot

8

Breaker Foot Latch

9

Trigger

10

Trigger Lock

11

Accumulator

12

Handle

13

Hydraulic Supply Ports

14

Type “D” Decal (CE Models)

15

STANLEY Logo Decal

16

Hex Shank Length Decal

17

Breaker Foot

18

Breaker Foot Latch

19

Composite Safety Decal

20

Sound Power Level Decal

21

CE Decal

22

Accumulator Valve Cap

Tool Setup - Detail B

Do not install or change tool accessories while the

hydraulic power source is connected. Accidental

engagement of the tool can cause serious injury.

Disconnect the hydraulic power source before installing

or changing accessories.

1. Disconnect the tool from the hydraulic power source.

Install the Breaker Bit

The tool bit can get extremely hot during operation.

Always wear gloves when installing bits. Hot bits can

cause burns.

2. Unlock the breaker foot latch.

3. Insert the tool bit and lock the latch. Never use BR67 unless the tool bit

is locked in the retainer.

Note: Never use a blunt tool bit as they cause more vibration.

Connect to a Hydraulic Power Source

4. Using a calibrated flow and pressure gauge, check the output of the

hydraulic power source. Ensure it matches the flow and pressure in

“Specifications” on page 11. Hydraulic fluid must be 50°F or above.

Preheat if necessary.

5. Ensure that the hydraulic power source is equipped with a relief valve

set to open at the maximum relief pressure. See “Specifications” on

page 11.

6. Wipe hose couplers with a clean, lint free cloth.

7. Connect the return hose to the tool port marked “Out”.

8. Connect the pressure hose to the tool port marked “In”.

9. Ensure couplers are undamaged, properly connected and are tight.

10. Power up the hydraulic power source.

Tool Operation - Detail C

Always hold tool with both hands to maximize control.

Apply proper down pressure and maintain proper

footing at all times.

1. Wrap your hands around the handles. Stand in back of the tool, using

your leg against the snap-on filler for stability.

Note: Hold the tool correctly and be ready to counteract normal or sudden

movements. Have both hands available.

2. Place the breaker bit on the material to be broken, at a 90° angle.

Apply down pressure.

3. Flip the trigger lock (CE models only).

4. Slowly squeeze the trigger to start breaking. Squeeze harder for fast

speed operation.

5. When starting, break until the tool bit breaks through, then reposition

the bit. Do not use the tool bit as a lever to move material.

Note: Never cool a hot tool bit in water. Tools can become brittle and fail.

6. Continue breaking around the original hole, in 2 inch sized bites.

7. Release Trigger to stop the tool.

Note: If you encounter a breakdown or the tool stops for any reason, release

the trigger and power down the hydraulic power source.

Loading...

Loading...