18 ► HD45 User Manual

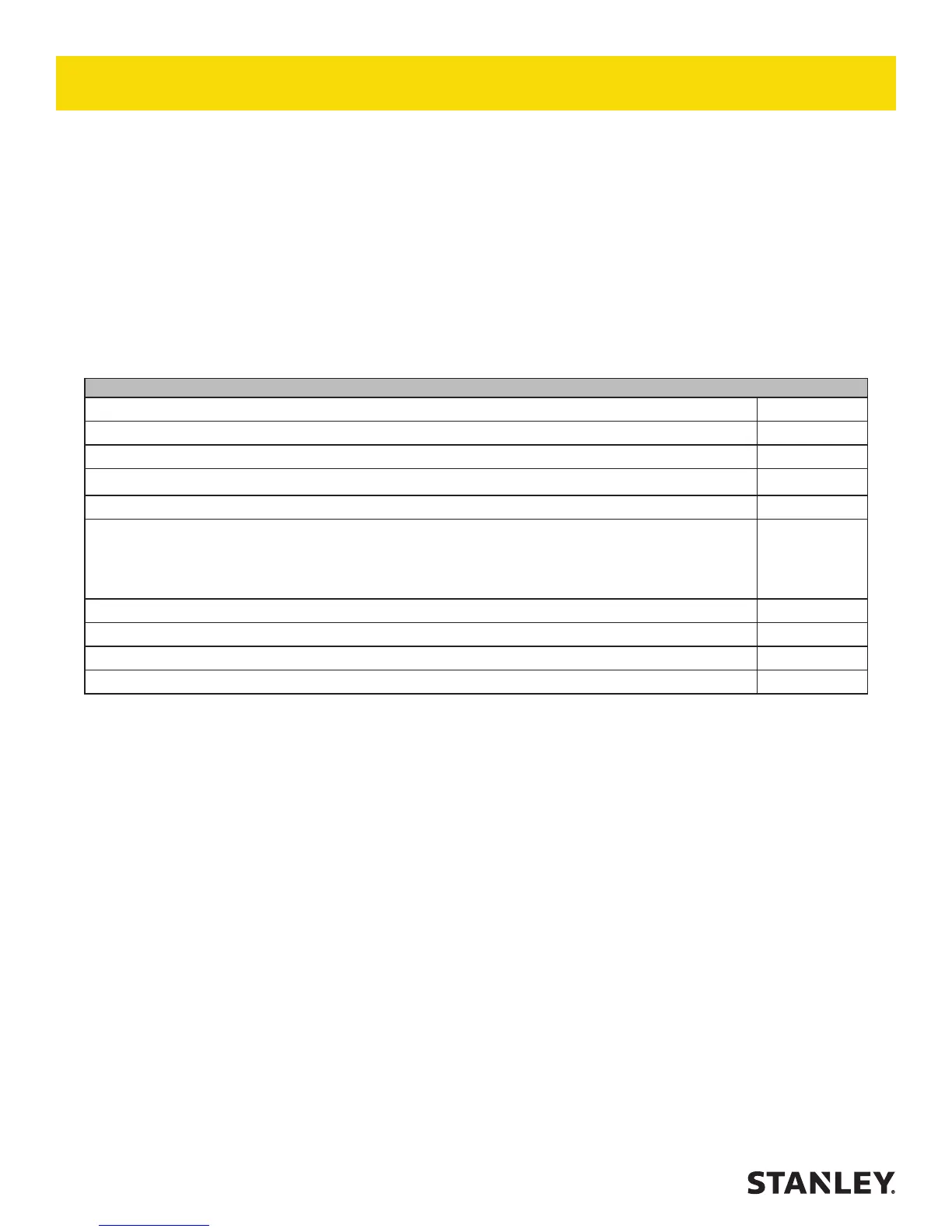

Operating Pressure ........................................................................................................1500-2000 psi / 105-140 bar

Flow Range ............................................................................................................................ 7–9 GPM / 26–34 LPM

Optimum Flow ................................................................................................................................. 8 GPM / 30 LPM

Capacity....................................................................1 to 2 in. / 25–50 mm Dia. No. 736 Skil Carbide Tipped Drill Bit

Porting ....................................................................................................................................................8 SAE O-ring

Connect Size and Type ................................................................................................... 3/8 in. Male Pipe Hose End

System...............................................................................................Open Center, HTMA Type II/ETMA Category D

Rotating Speed .......................................................................................................0-300 RPM (Forward or Reverse)

Hose Whips ........................................................................................................................................................... Yes

Weight .................................................................................................................................................. 45 lb / 20.4 kg

Length.............................................................................................................................................. 24.5 in. / 62.2 cm

Motor ...............................................................................................................................................................Integral

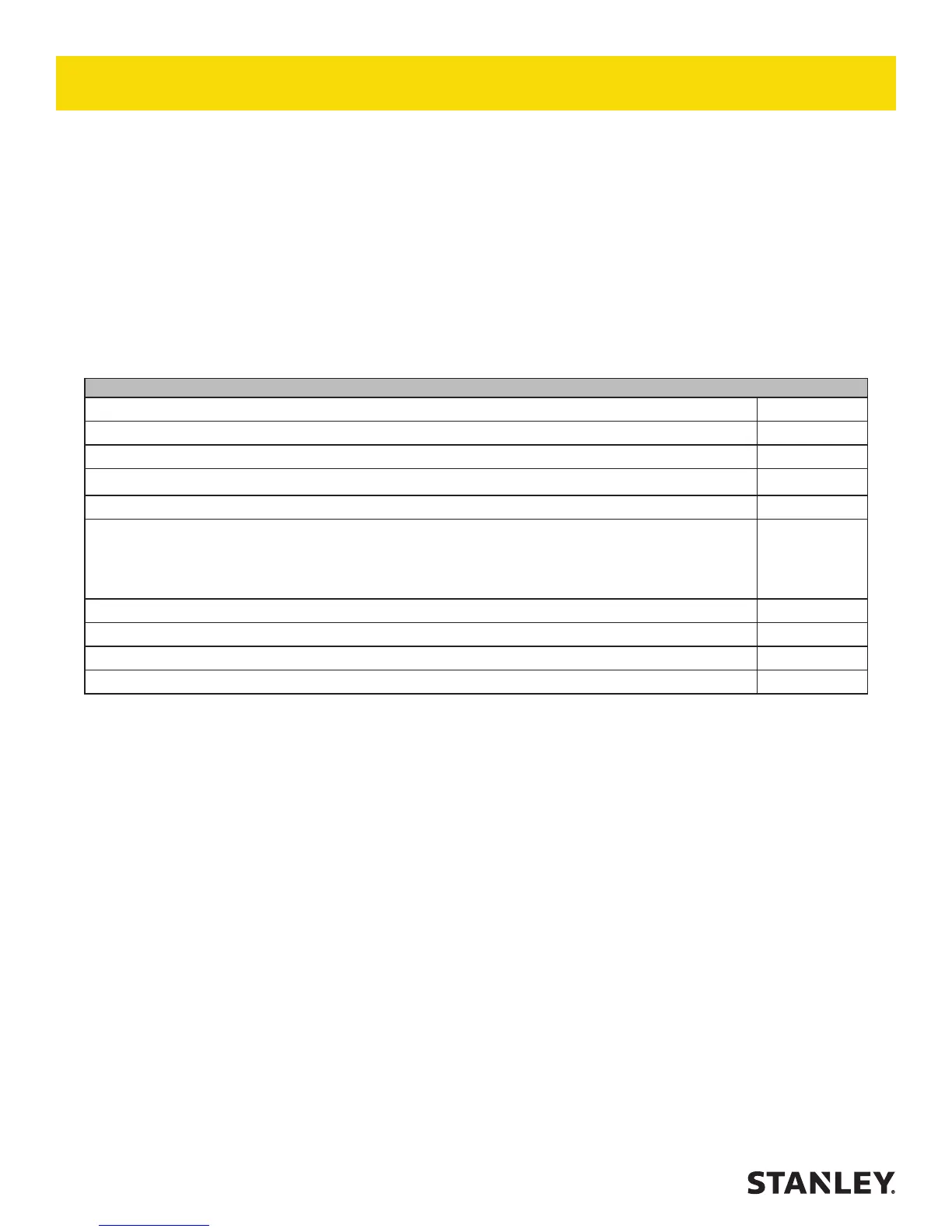

SOUND POWER AND VIBRATION DECLARATION

Test conducted on HD45310E, S/N 5606.

Measured A-weighted sound power level, Lwa (ref. 1pW) in decibels 111.8 dBA

Uncertainty, Kwa, in decibels 3.39 dBA

Measured A-weighted sound pressure level, Lpa (ref. 20 µPa) at operator’s position, in decibels 103.8 dBA

Uncertainty, Kpa, in decibels 3.39 dBA

Values determined according to noise test code given in ISO 15744, 11203 and 3744.

NOTE: The sum of a measured noise emission value and its associated uncertainty

represents an upper boundary of the range of values which is likely to occur in

measurements.

Declared vibration emission value in accordance with EN ISO 28927-10

Measured vibration emission value: a (Trigger Handle) 14.9 m/sec²

Measured vibration emission value: a (Non-Trigger Handle) 17.5 m/sec²

Uncertainty: K 2.23 m/sec²

ACCESSORIES

Carbide Bit 1 in. × 24 in. Long (Drills 14-7/8 in. Deep) ......................................................................................02281

Carbide Bit 1-1/4 in. × 24 in. Long (Drills 14-7/8 in. Deep) ................................................................................ 02282

Carbide Bit 2 in. × 24 in. Long (Drills 14-3/4 in. Deep) ......................................................................................02283

Carbide Bit 1 in. × 18 in. Long (Drills 8-7/8 in. Deep) ........................................................................................04668

Carbide Bit 1-1/4 in. × 36 in. Long (Drills 29 in. Deep) ......................................................................................04896

SERVICE TOOLS

Tamper Sleeve Tool ........................................................................................................................................... 01120

Accumulator Tester ............................................................................................................................................02835

Flow and Pressure Tester .................................................................................................................................. 04182

O-ring Tool Kit .................................................................................................................................................... 04337

Flow Sleeve Removal Tube ...............................................................................................................................04910

Flow Sleeve Removal Tool ................................................................................................................................04919

Bearing Installation Tool ....................................................................................................................................05044

Latch Removal Tool ...........................................................................................................................................05045

Bearing Installation Tool ....................................................................................................................................05061

Latch Installation Tool ........................................................................................................................................05062

Accumulator Cylinder Puller ..............................................................................................................................05640

Seal Kit ..............................................................................................................................................................05839

Latch Installation Tool ........................................................................................................................................05879

Accumulator Charge Kit.....................................................................................................................................31254

SPECIFICATIONS

Loading...

Loading...