6

OUTLET

VALVE

START-UP

CHECKING THE OIL

1. Check the oil level before operation. Fill the Pump Crankcase with 30W

non-detergent Air Compressor Oil.

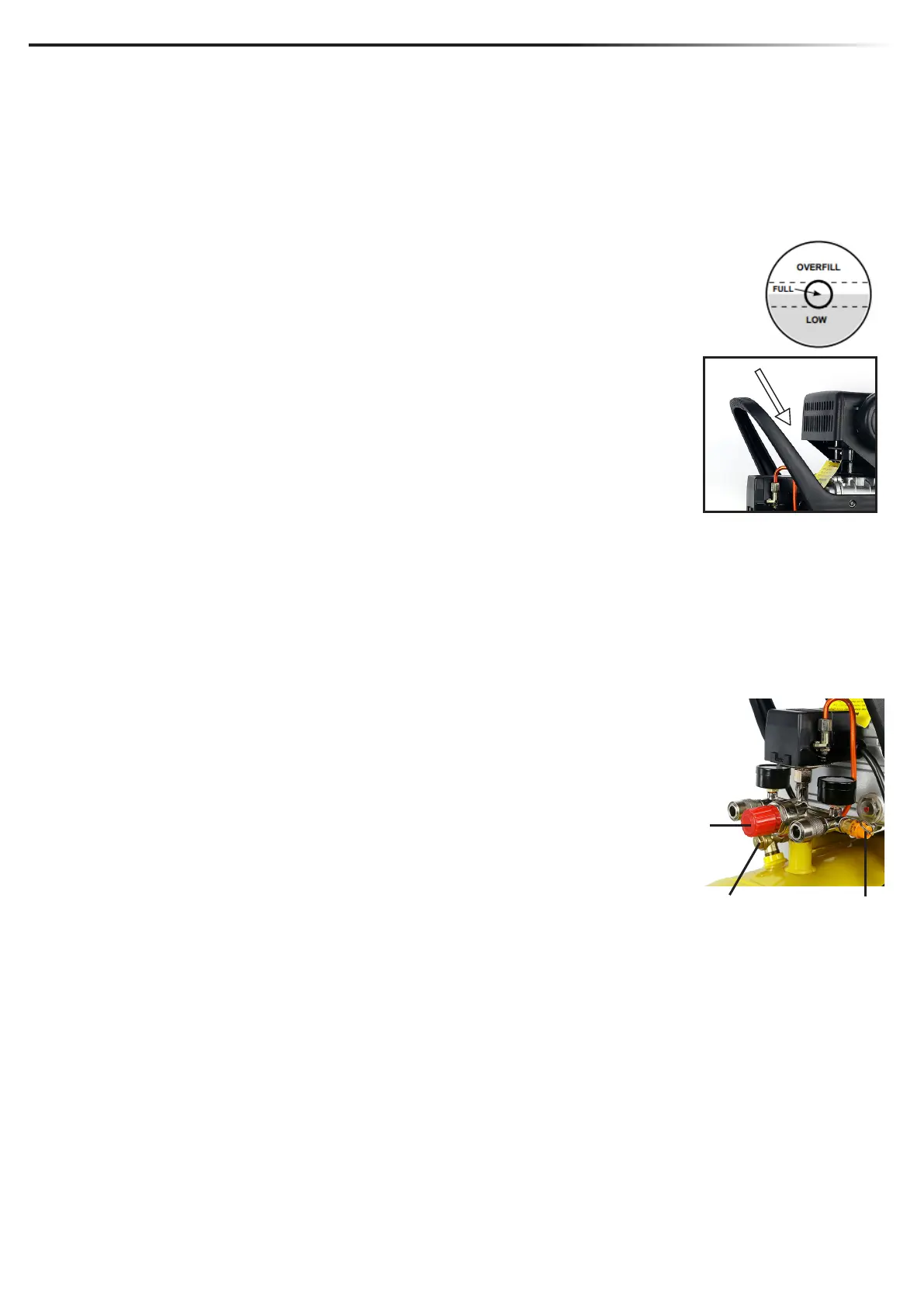

2. The oil level should be at the center of the “full” level on the Oil Sight

Gauge. Add oil as needed to maintain this level. Do not let the oil level go

below the center dot and do not overll the oil so that it is above the center

dot.

3. To add oil:

a. Remove the Oil Breather Plug

b. Using a funnel to avoid spills, pour enough

oil into the pump crankcase to reach the “full” level in the Oil Sight Glass.

c. Replace the Oil Breather Plug

WARNING: TO PREVENT BURN INJURY DO NOT add or change the oil while the compressor is in

operation. Allow the compressor to cool before replacing oil.

OPERATION AND ADJUSTMENTS

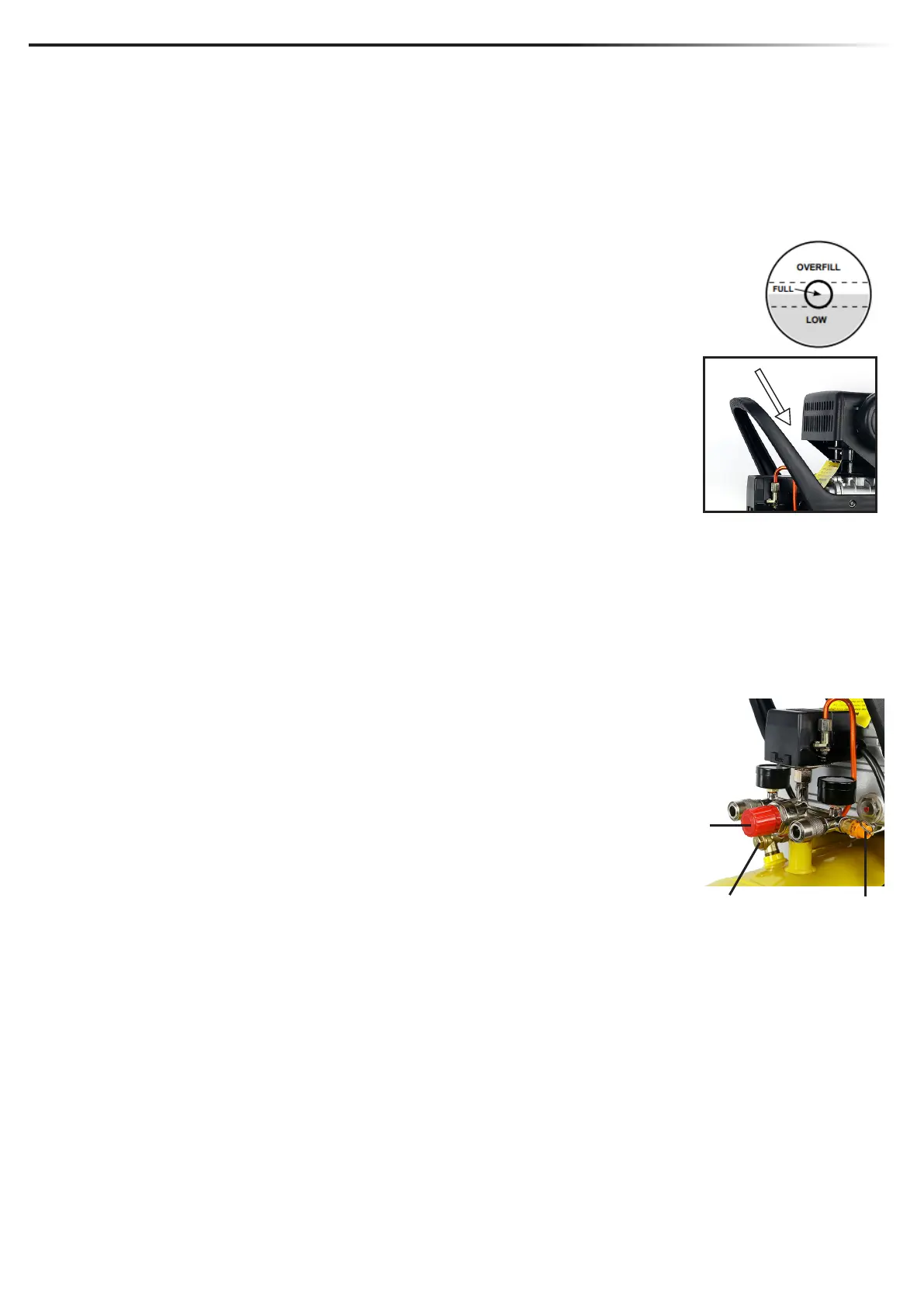

1. Adjust the Regulator so that the air output is enough to properly power

the tool, but the output will not exceed the tool’s maximum air pressure

at any time. Turn the Regulator clockwise to increase the pressure, and

counter-clockwise to decrease pressure. Adjust the pressure gradually

while checking the Output Pressure Gauge to set the pressure.

DISCHARGE

VALVE

SAFETY

VALVE

ADJUSTING

SCREW

BREAKING IN THE COMPRESSOR

1. Turn the Power Switch off and unplug the unit. Insert a male coupler (sold separately) into the female

Quick Coupler and fully open all regulators and valves.

2. Plug in the Power Cord.

3. Turn the Power Switch ON.

4. Let the unit run for 30 minutes. Air will expel freely through the Coupler.

5. Turn the power switch ON.

6. Unplug the Power Cord and remove the male coupler.

NOTE: At the beginning of the day’s rst use of the Air Compressor, check for air leaks by applying

soapy water to connections while the Air Compressor is pumping and after pressure cut out. Look

for air bubbles. If air bubbles are present at connections, tighten connections. Do not use the Air

Compressor unless all connections are air tight, the extra air leaking out will cause the compressor to

operate too often, increasing wear on the compressor.

Loading...

Loading...