Page 35

APPENDIX F

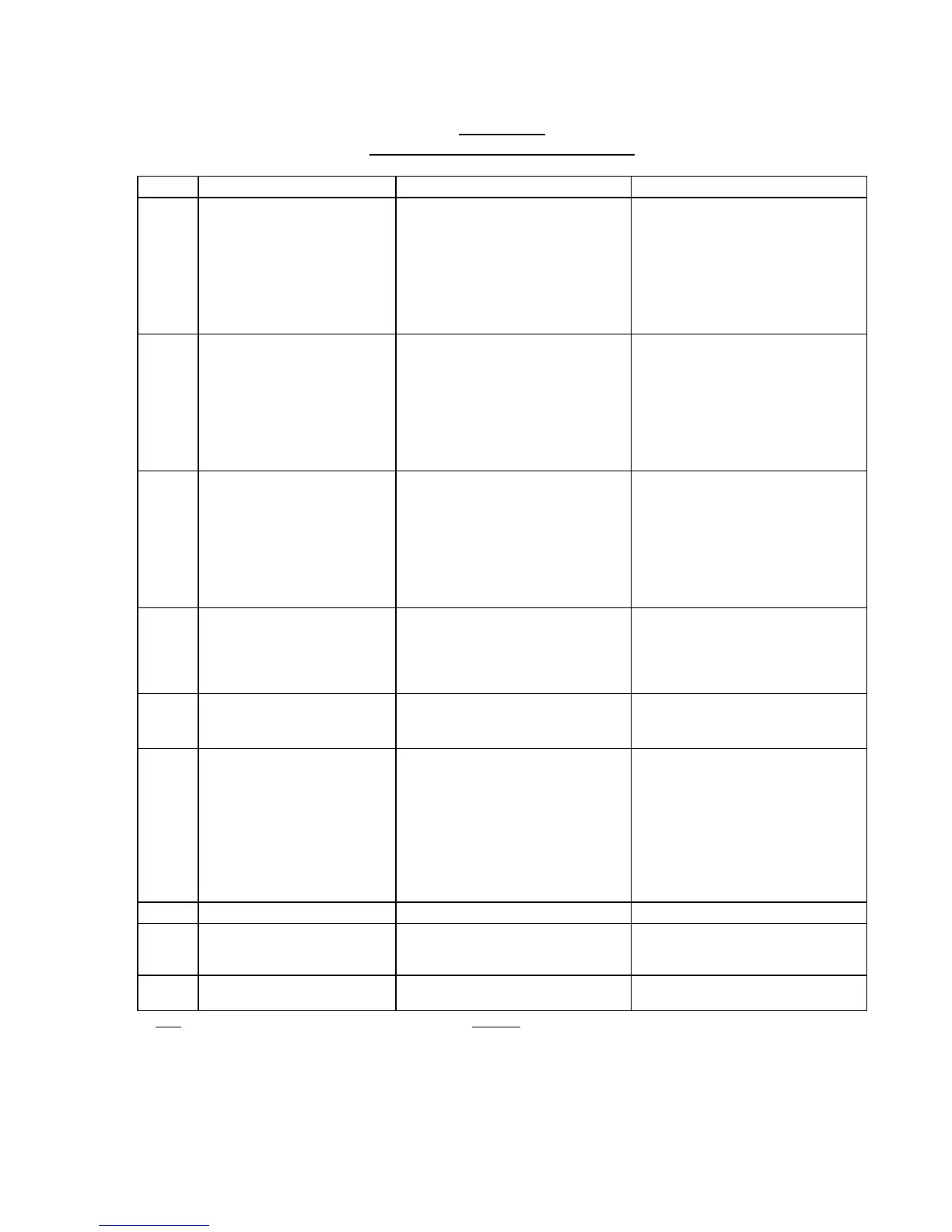

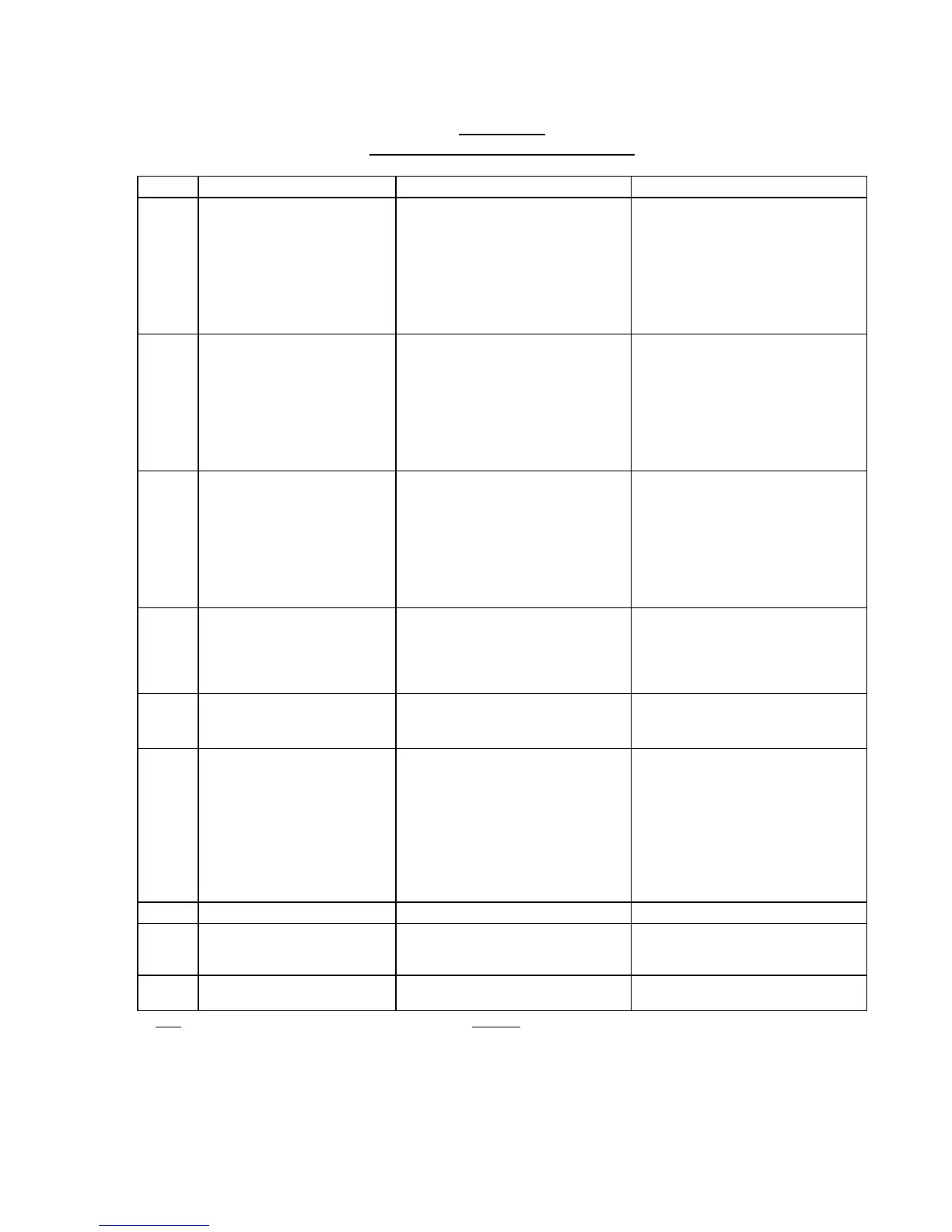

ALARM CODES / TROUBLESHOOTING

Code Alarm Probable Cause Corrective Action

A1 High Temperature 1. Refrigerator temperature higher

than temperature alarm setting.

(On initial fill, refrigerator will take

approx. 24 hours to reach normal

operating temperature.)

2. Thermocouple faulty.

1. Change temperature alarm setting

(see systems set-up procedure) or

raise sensor positions to increase

liquid level in refrigerator. (Vapour

phase only.)

2. Re-calibrate thermocouple (see

appendix D) or replace if problem

persists.

A2

A3

A4

A5

Sensor Open Circuit (Extra High)

(White wire)

Sensor Open Circuit (High)

(Yellow wire)

Sensor Open Circuit (Low)

(Blue wire)

Sensor Open Circuit (Extra Low)

(Red wire)

1. Loose wire on corresponding

sensor.

1. Check wiring connections and

repair as necessary.

A6

A7

A8

A9

Sensor Short Circuit (Extra High)

(White wire)

Sensor Short Circuit (High)

(Yellow wire)

Sensor Short Circuit (Low)

(Blue wire)

Sensor Short Circuit (Extra Low)

(Red wire)

1. Sensor damaged or loose wiring on

sensor assembly causing short

circuit.

1. Repair connection or replace

sensors if necessary.

A10 Time-out on filling 1. Liquid nitrogen supply depleted.

2. Insufficient pressure in supply

vessel.

3. Filter blocked.

1. Replenish liquid nitrogen supply.

2. Increase supply vessel pressure.

(See page 7)

3. Thaw filter and replace if still

blocked. (See maintenance section)

A11 Time-out on lid open 1. Lid open timer alarm setting has

been exceeded.

1. Close lid or adjust lid open alarm

setting if required. (See system

set-up procedure.)

A12 Overfill 1. Excessive supply pressure causing

liquid level in sensor tube to

fluctuate and reach extra high

sensor.

2. Solenoid valves not functioning

correctly due to ice contamination

or damaged relays.

1. Reduce supply vessel pressure.

(See page 7)

2. Shut off liquid nitrogen supply.

Allow solenoid valves to thaw.

Re-introduce liquid nitrogen supply

and if problem persists contact

service engineer.

A13 Underfill (low level) # See note. See A10 “Time-out on filling”.

A14 Printer faulty/unavailable. 1. Printer disconnected from

Biosystem/no power to printer.

1. Check printer connection and

power

supply.

A15 Thermocouple open circuit.

(Blue & white wire)

1. Loose wire from thermocouple.

2. Thermocouple damaged.

1. Repair connection.

2. Replace thermocouple.

# Note : If alarm A13 occurs and the refrigerator has actually overfilled this may indicate that the vent on the sensor tube has become

blocked by a build up of ice. By removing the black grommet which is located to the right of the grey top cover (when lid is open), the

sensor tube with the cable gland at the top can be seen. Just below this gland the vent tube branches off and points down. The ice

should be removed from the vent tube and if this does not rectify the problem a service engineer should be called.

F-1

Loading...

Loading...