MAINTENANCE MANUAL

STEMME TSA-M

MAINTENANCE MANUAL

STEMME TSA-M

Page 04

05-20-00

Page 05

05-20-00

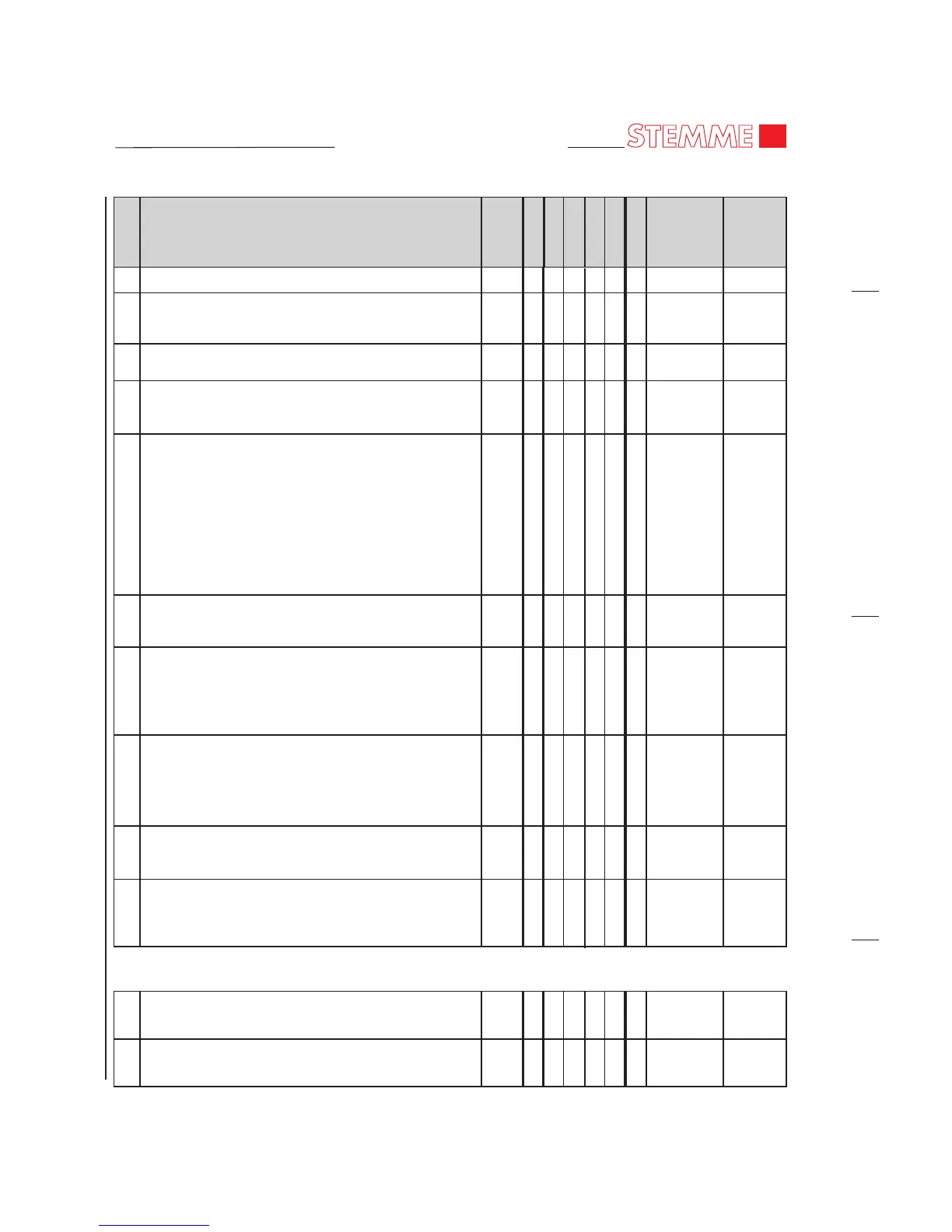

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

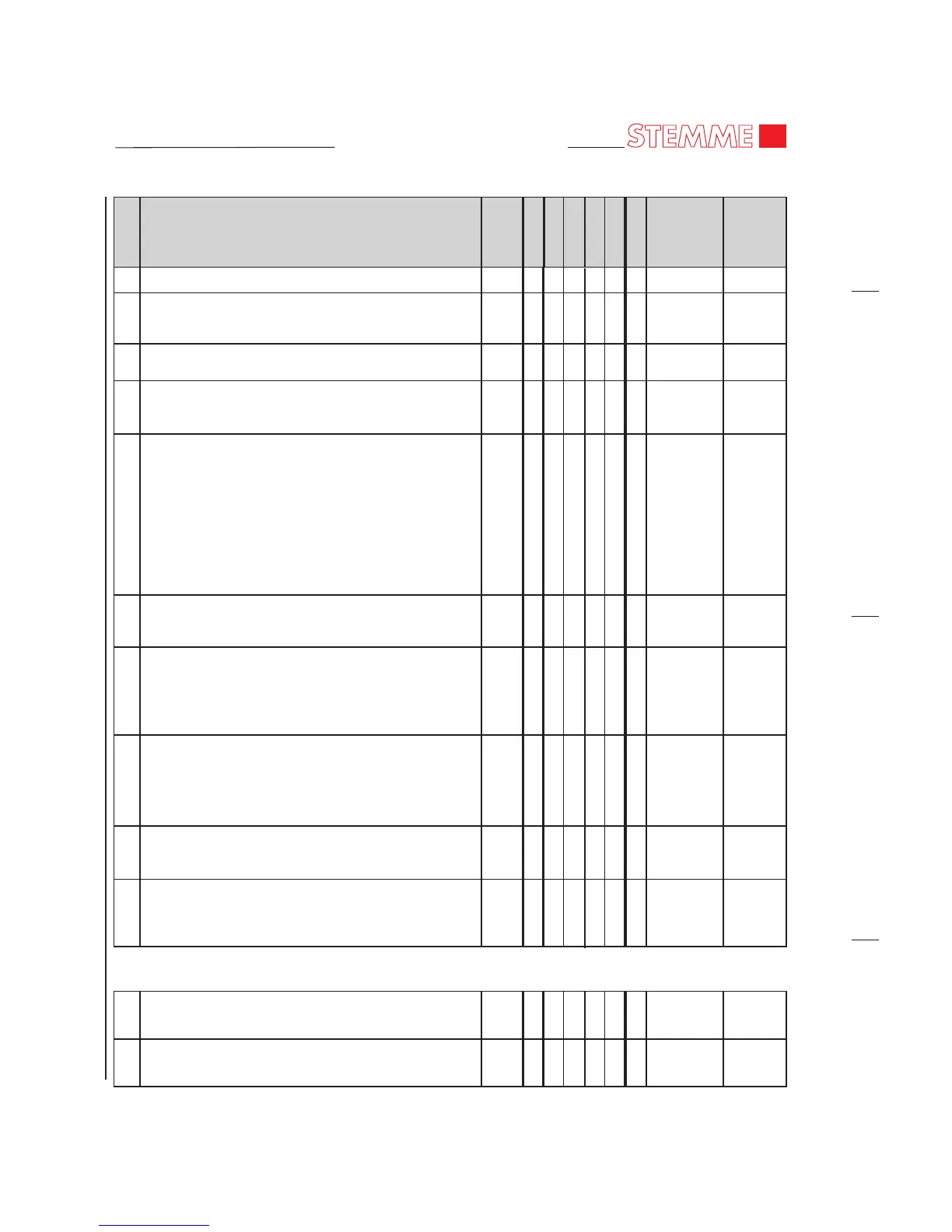

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

3. Check security and condition of drive gear

cowlings. Clearance allowed (all around):

1 +1.0, -0.5 mm / 0.04 + 0.04, -0.02 in

1. Inspect canopy for damage and check proper

function of locking mechanism, grease canopy

locks. Clearance allowed (all around):

2 ± 1.0 mm / 0.08 ± 0.04 in

2. Canopy emergency jettison: Check function.

3. Check function of lateral canopy gas springs

(canopy must remain in open position).

4. Check seat belts and their attachments.

5. Check controls in front fuselage for foreign objects,

condition and proper installation.

6. Check condition and security of all instruments,

switches, circuit breakers, fuses and wiring.

7. Check condition and integrity of ventilation hoses.

8. Check rudder pedals and control cables. Check

provisions for pedal adjustment.

Play allowed (at rudder, with pedals fixed,

measured in direction of movement):

max. 2.5 mm / 0.1 in

9. Check condition, security and adjustment

mechanism of the seats.

1. Check condition of center fuselage steel frame

(corrosion, deformation). Check paint for cracks.

2. Check condition of framework/tailboom

connection.

3. Check condition of upper and lower connection

framework / front fuselage.

5.1.5 Center Fuselage (except for fairings)

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

5.1.4 Cockpit

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

5.1.3 Front Fuselage

3. Check vent line outlets at end ribs of central wing.

4. Check function and leak tightness of quick-release

couplings (supply lines) to and from fuselage.

5. Check all fuel filters and replace if required.

6. Check fuel filler cap for leakage and wing for any

signs of wing fuel tank leakage.

7. Check condition and backlash of wing fittings,

check safety device of wing attachment bolts.

Maximum play allowed for all wing bolts:

Axial: 0.4 mm / 0.016 in

Radial: 0.15 mm / 0.006 in

For front and aft shear force bolts (inner wing -

outer wing, outer wing - winglet) only radial play is

allowed.

8. Check condition, security and function of fuel

pumps (located under the spar).

9. Check condition of wing flaps and ailerons, check

clearance between components spanwise 3 ± 0.5

mm / 0.12 ± 0.02 in., check gap sealings and fairings

on flap/aileron links, check security of axial stops.

10. Check entire control linkage and bearings in the

center wing and in the wing attachment area,

verify the spring pin on each quick-connector is

attached securely.

11. Inspect bell-crank levers and adjacent components

of wing flap and aileron control system.

12. Check condition of airbrakes.

Clearance between cover strap and wing shell

(spanwise, overall): 4 ± 0.5 mm / 0.16 ± 0.02 in

1. Check condition and security of drive gear

attachment.

2. Verify the gap between Center wing and fuselage is

at least 2 ± 0.5 mm / 0.08 ± 0.02 in.

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

(X)

X

X

X

Nov 18/11

Nov 18/11

Loading...

Loading...