MAINTENANCE MANUAL

STEMME TSA-M

MAINTENANCE MANUAL

STEMME TSA-M

Page 06

05-20-00

Page 07

05-20-00

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

Nov 18/11

Nov 18/11

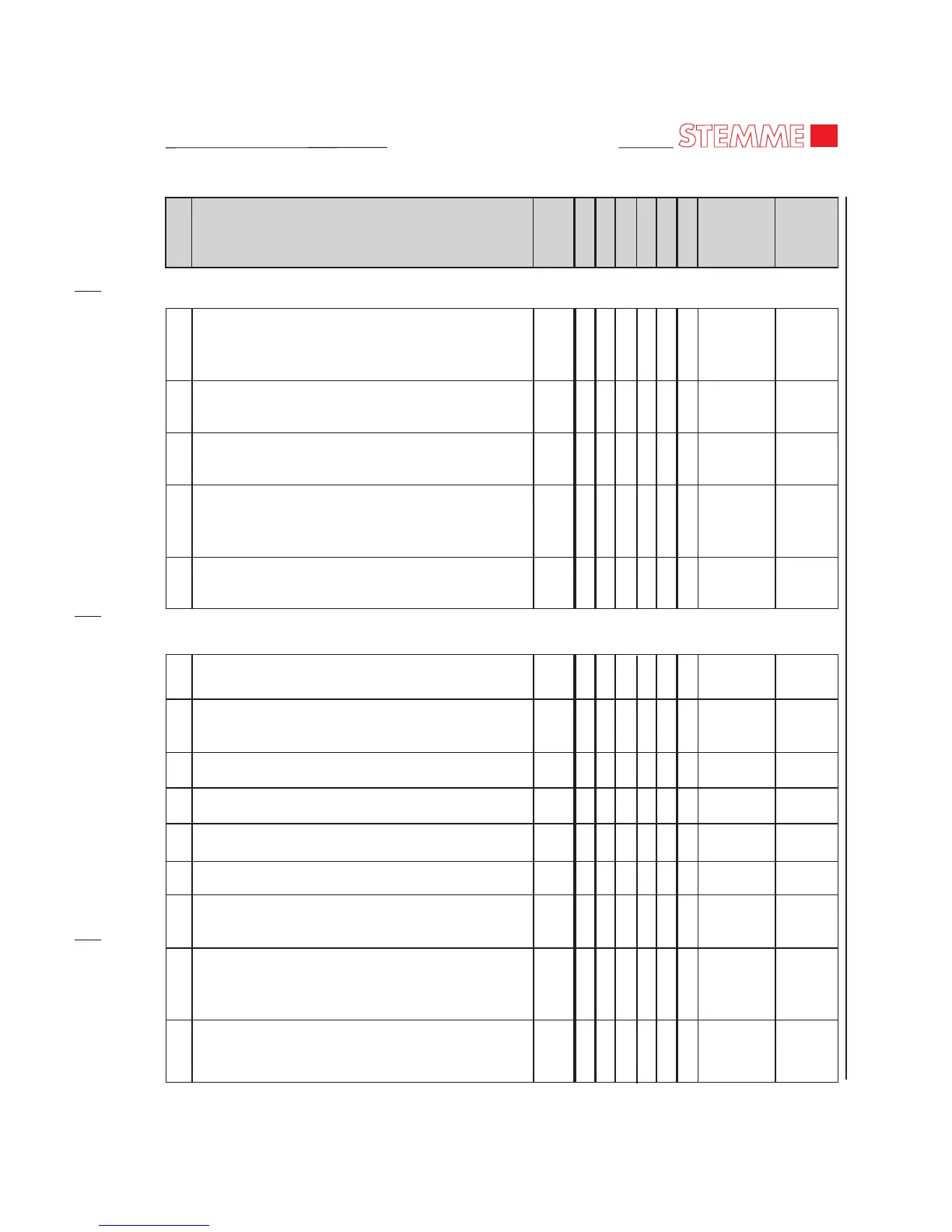

1. Check condition of supply, return and drain lines

outside the engine compartment, supply and

return lines inside the engine compartment.

2. Check condition, security and function of fuel

pumps.

3. Replace main fuel pump. (acc. to ROTAX)

4. Check fuel shut-off valve. Inspect firewall

feedthroughs of the fuel supply and return lines for

security and leakage.

5. Check condition of fire protective sleeves on fuel

supply and return lines in the engine compartment.

1. General visual inspection of engine and auxiliaries

for damage, abnormalities and leakage.

2. Check friction torque in free rotation of engine gear

box.

3. Inspect overload clutch.

4. Check of the engine gear box.

5. Check of fuel filters, renew if necessary.

6. Check idle speed.

7. Inspect float chamber assembly for contamination

and corrosion at minimum one time a year.

8. Check of carburetors with inspection of ventilation

of the float chambers and disassembling/assembling

for checking.

9. Check carburetor synchronization.

5.1.9 Engine and Engine Mounts

X

X

X

X

(X)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

X

X

X

X

X

X

X

X

X

X

X

(1)

X

X

X

R* 05-20-00

28-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

5.1.8 Fuel System Components in the Fuselage

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

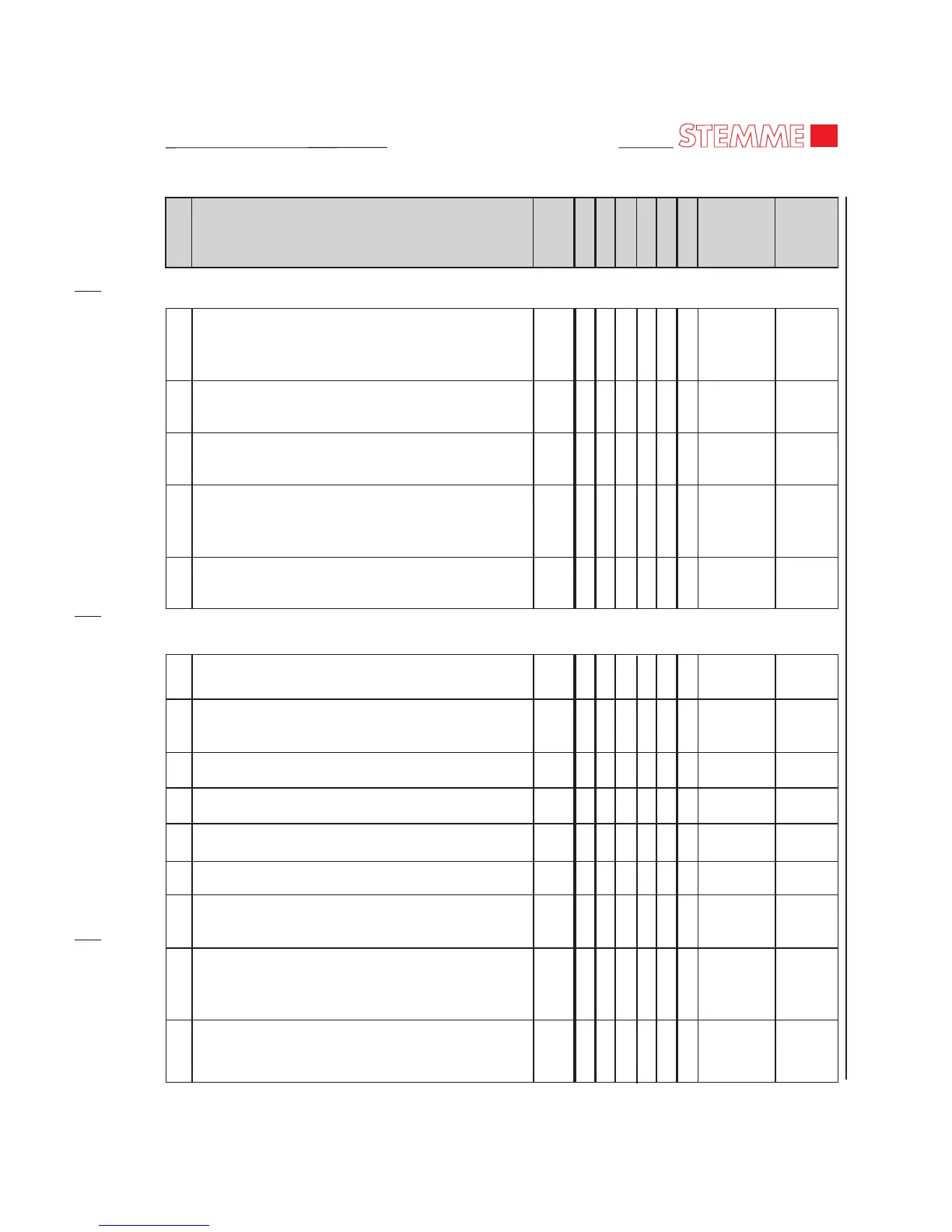

4. Check condition and security of landing gear

attachment.

5. Check condition of entire control linkage in the

center fuselage.

6. Main battery: Check electrical terminals, condition

and security of mounting tray.

1. Visual inspect members of elevator control looking

into the forward and aft end of tail boom.

2. Visual inspect members of rudder control looking

into the forward and aft end of tail boom.

3. Check trim control system.

4. Check tail skid for security and wear.

5. Check attachment of ballast compartment for

cracks.

6. Check baggage compartment door for correct

closure.

7. Check attachment points in the baggage

compartment for security.

1. Check rudder system and fittings for condition and

security. Play allowed (hinges):

only axial: 0.4 ± 0.1 mm / 0.016 ± 0.004 in

2. Check backlash in fittings of horizontal stabilizer

when installed.

Maximum play allowed for front and aft fitting:

Axial: 0.15 mm / 0.006 in

Radial: 0.15 mm / 0.006 in

3. Check gap sealings and zigzag tape on the

empennage.

5.1.6 Tail Boom

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

5.1.7 Empennage

Loading...

Loading...