MAINTENANCE MANUAL

STEMME TSA-M

MAINTENANCE MANUAL

STEMME TSA-M

Page 08

05-20-00

Page 09

05-20-00

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

Nov 18/11

May 04/12

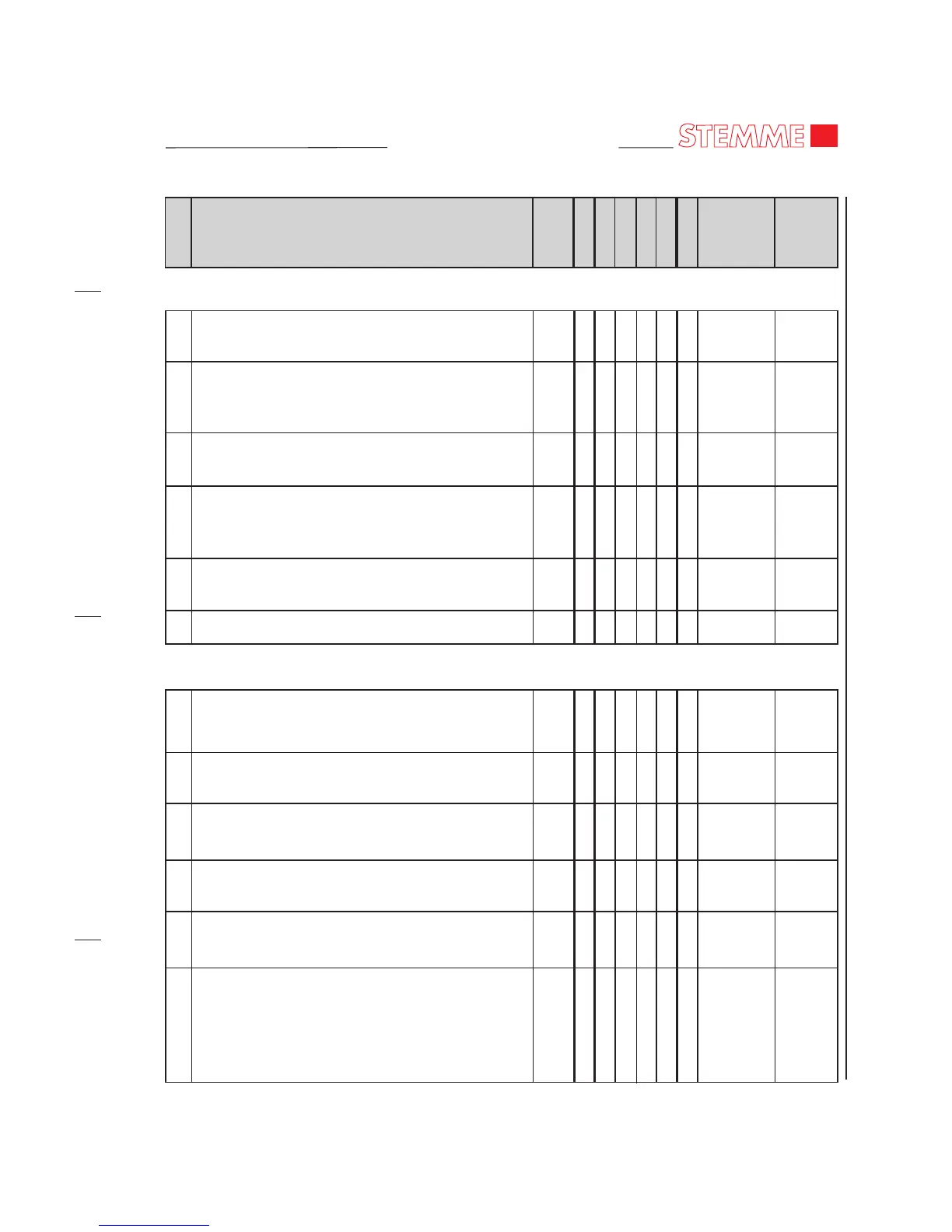

1. Check condition of oil radiator and oil tank

assemblies.

2. Check oil lines (from/to engine and turbocharger)

and oil drainline for condition, leakage and correct

routing.

3. Check condition and routing of fire protective

sleeves.

4. Oil change. Check drain screws of oil tank and

crankcase for metal particles or foreign matter with

every oil change.

5. Oil filter change. Inspect the old oil filter insert for

metal particles and foreign matter.

6. Check oil quantity after refilling.

1. Check the cooling system components: expansion

tank, refill container, overflow bottle (especially

ventilation bore) and radiator.

2. Check coolant level, replenish if necessary.

3. Check condition of coolant hoses and pipes, check

for leakage and correct routing.

4. Visual inspection of water pump for leakage

(leakage bore at the base of the water pump).

5. Flush the liquid cooling system when renewing

coolant.

6. Inspect cylinder shaft cooling fins for obstructions

and condition.

X

X

X

X

X

X

X

X

X

(X)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

X

X

X

X

X

X

X

X

X

X

X

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

12-14-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

12-12-00

12-14-00

5.1.11 Cooling System (Liquid Cooling, Ram Air Cooling)

5.1.10 Lubrication System

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

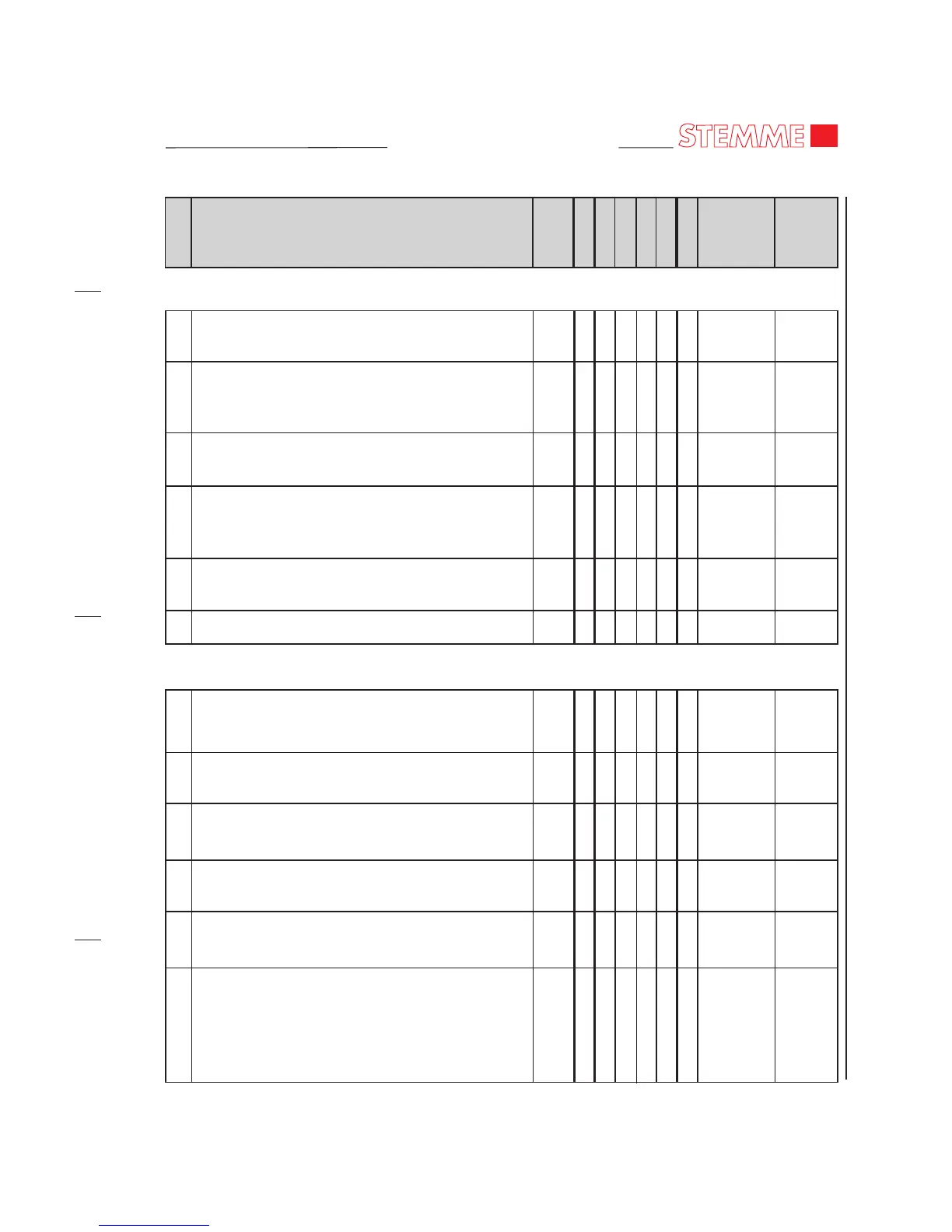

10. Inspect carburetor sockets for condition, damage.

11. Check condition of fuel lines, pressure connection

lines and compensating tube assy at the

carburetor’s airbox. Check for leakage and correct

installation.

12. Check engine wiring and its connections for secure

fit and damage.

13. Check the V-belt tension and attachment of

auxiliary generator.

14. Check spark plugs and renew them if necessary.

15. Replace spark plugs.

16. Check spark plug connectors for tight fit.

(Minimum pull-off force is 30 N / 7 lb)

17. Check compression pressure by differential

pressure method.

18. Check mountings of turbocharger, muffler and

other external parts for tight fit. Inspect safety

wiring, renew if necessary.

19. Check condition of exhaust elbows and exhaust

system for crack formation and uncharacteristic

gunpowder burns (leaks).

20. Check mounting points of the engine at the engine

frame (engine mounts).

21. Check engine frame for condition, crack formation

and deformation.

22. Perform engine cleaning after completion of all

maintenance steps for the engine (after completion

of 5.1.13).

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

R* 05-20-00

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

(1)

X

X

X

X

X

(X)

(X)

(X)

(X)

(1)

X

(X)

(X)

(X)

(X)

(X)

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

Loading...

Loading...