MAINTENANCE MANUAL

STEMME TSA-M

MAINTENANCE MANUAL

STEMME TSA-M

Page 10

05-20-00

Page 11

05-20-00

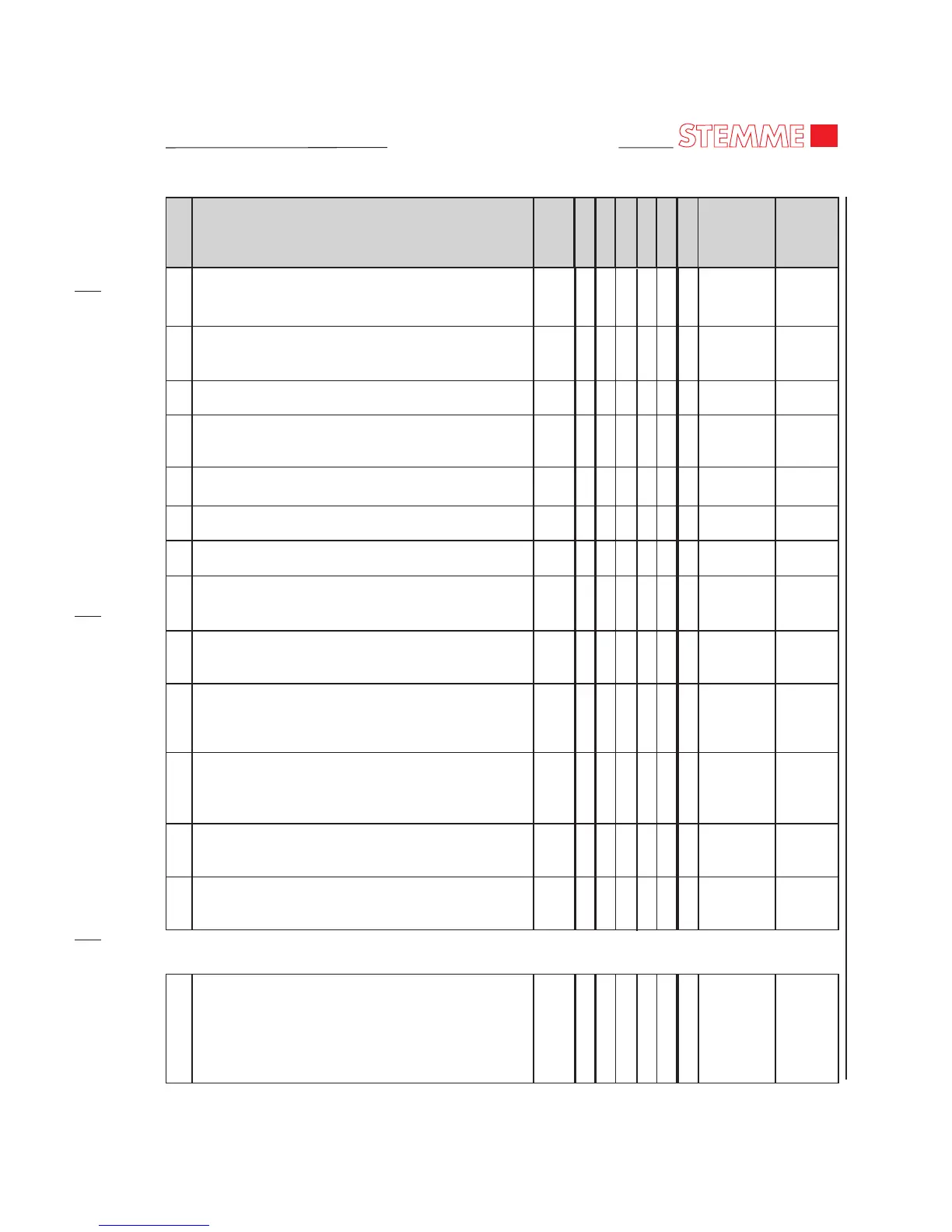

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

2. Check blades and all visible hub parts for cracks,

deformation, position and security.

3. Check cable routing, cable condition and

connection.

4. Check carbon brush block and slip rings for wear.

5. Check spinner and back plates for cracks and

security.

6. Check all locks for function.

7. Check flange bolts and stop nuts for correct torque.

8. Check function of the electric actuation motor.

9. Clean slip rings and carbon brushes (must be free

from oil and grease).

10. Verify the blade tip play is max. 3 mm (1/8 in.), and

the angular play is max. 2°.

11. Visual inspection of the propeller blades. Repair

erosion sheath if necessary or replace it (use only

material from the manufacturer!).

12. Check adjustment of propeller blade T/O and

cruise pitch. Check respective setting of blades and

check for discrepancies.

13. Check function of pitch change and time for pitch

change in each direction.

14. Check propeller blade T/O-position indication and

pre-setting before reaching T/O-position.

1. Check condition and security of drive shaft flanges

(paint markings).

Check of engine-side drive-shaft flange connection.

Visually check M8 bolt connection, self-locking nuts

and locking varnish.

X

X

X

X

X

X

X

X

X

X

X

X

(X)

X

X

X

X

MT**/6

MT**/6

MT**/6

MT**/6

MT**/6

MT**/6

MT**/6

MT**/6

MT**/6

MT**/6, 7

MT**/6

MT**/6

MT**/6

5.1.16 Drive Shaft with Front Gear

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

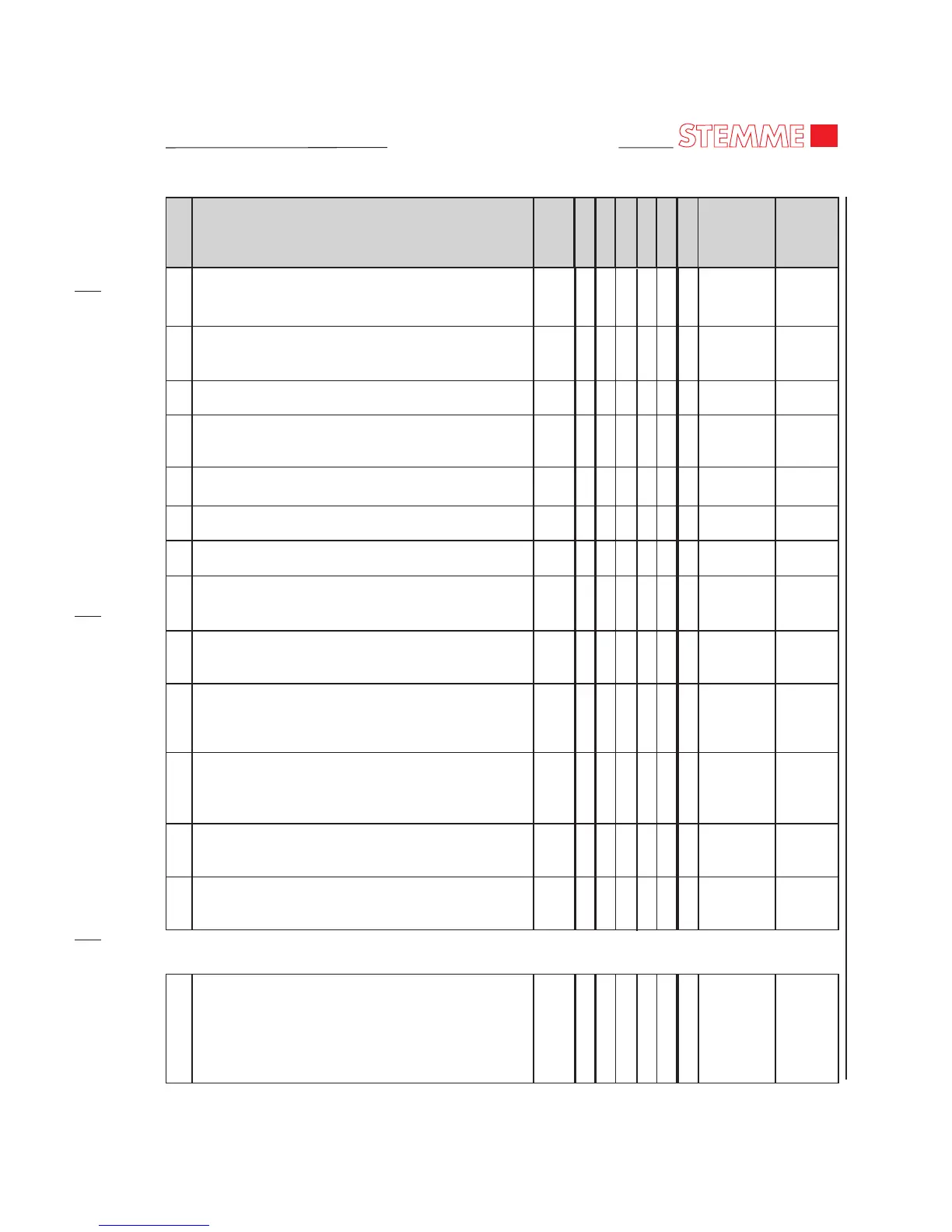

1. Check condition of air filter.

1. Throttle and choke: Check end stops of carburetor

controls, springs and condition of bowden-cables.

2. Check TCU and waste gate servo assy for condition

and free movement.

3. Check oil pressure sensor, oil temperature sensor,

cylinder head temperature sensor, exhaust gas

temperature sensor (if installed), fuel pressure and

fire warning sensors (if installed) for condition and

security.

4. Check function of engine instruments.

1. Check condition of upper center fuselage fairing.

Clearance allowed to surrounding parts (all

around): 1 ± 0.5 mm / 0.04 ± 0.02 in

2. Check condition of LH and RH engine cowling

(Clearance allowed refer to pt. 1).

3. Check condition of the fire protective painting of

the cowling. Repair if necessary.

4. Check condition and verify function of inlet and

outlet cowl flaps (fully opened and fully closed

position). Check the flaps close correctly.

5. Check condition of firewall sheets.

1. Remove spinner dome.

5.1.13 Engine Controls & Monitoring

12-13-00

R* 05-20-00

R* 05-20-00

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

(X)

(X)

(X)

(X)

(X)

X

X

5.1.12 Air Induction System

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

5.1.14 Center Fuselage Fairing, Engine Cowlings and Fire-Wall

5.1.15 Propeller

Nov 18/11

Nov 18/11

Loading...

Loading...