MAINTENANCE MANUAL

STEMME TSA-M

MAINTENANCE MANUAL

STEMME TSA-M

Page 12

05-20-00

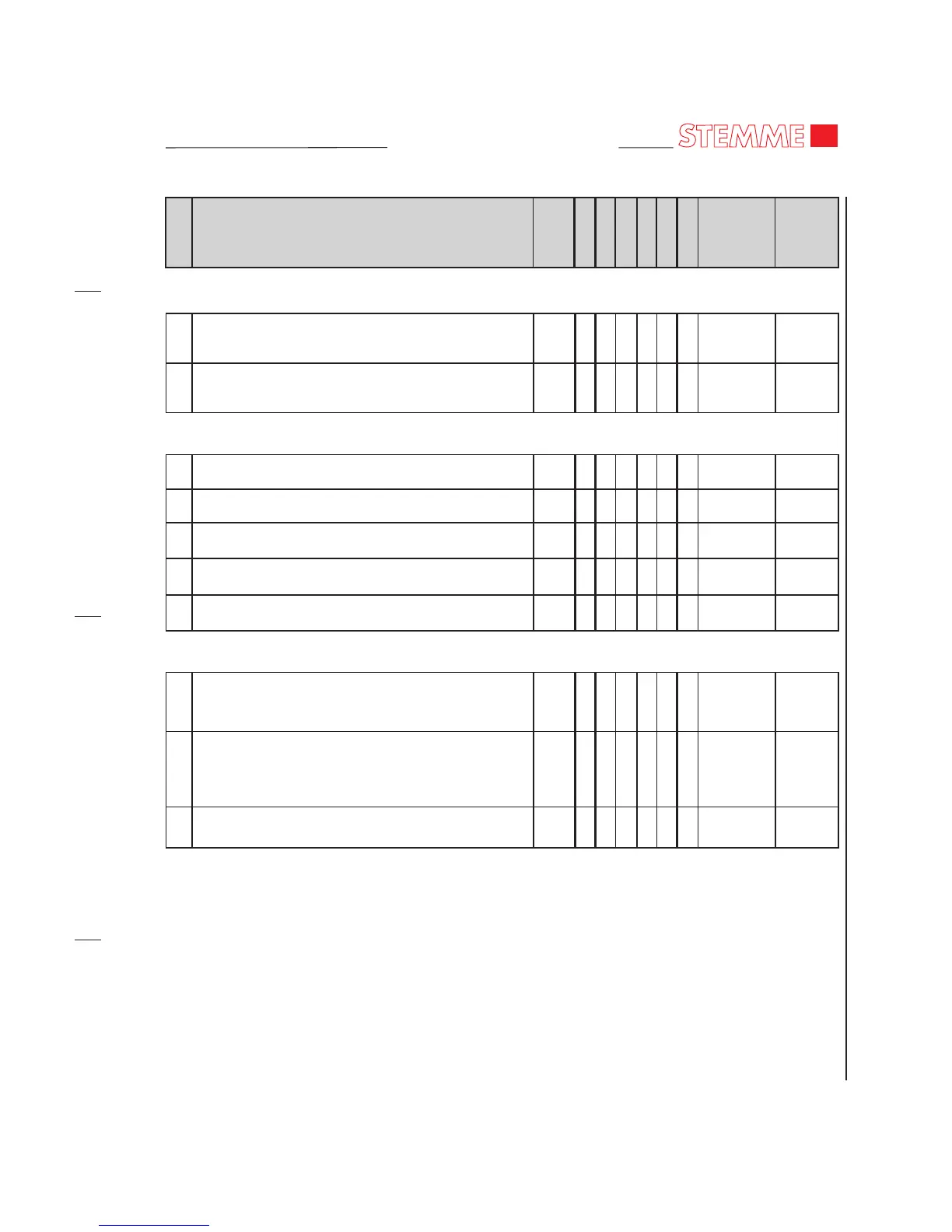

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

Page 13

05-20-00

* ROTAX Maintenance Manual (ref. 00-00-00, 2.A), Cha./para.

** mt-propeller, E-118 (ref. 00-00-00, 2.A), /para.

(1) if more than 30% of operation with leaded fuel (AVGAS 100 LL)

1. Check condition of pressure system , renew

filters/water separators if required.

2. Check condition and function of flight instruments

(refer to equipment list).

1. Check wiring of the electric system.

2. Check condition of all electrical devices installed.

3. Check condition and function of all switches.

4. Check condition of all ground terminals.

5. Visually check electric distribution box.

1. Check NAV and COM equipment for proper

installation and security and compare to equipment

list.

2. Check condition, function and, if applicable, service

life limits of NAV and COM equipment (refer to

records of operating times).

3. Check all antennas installed.

X

X

X

X

X

X

X

X

X

X

5.1.20 Electrical System (except for engine and TCU)

5.1.21 COM / NAV Equipment

5.1.19 Flight Instrumentation and Pressure Systems

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

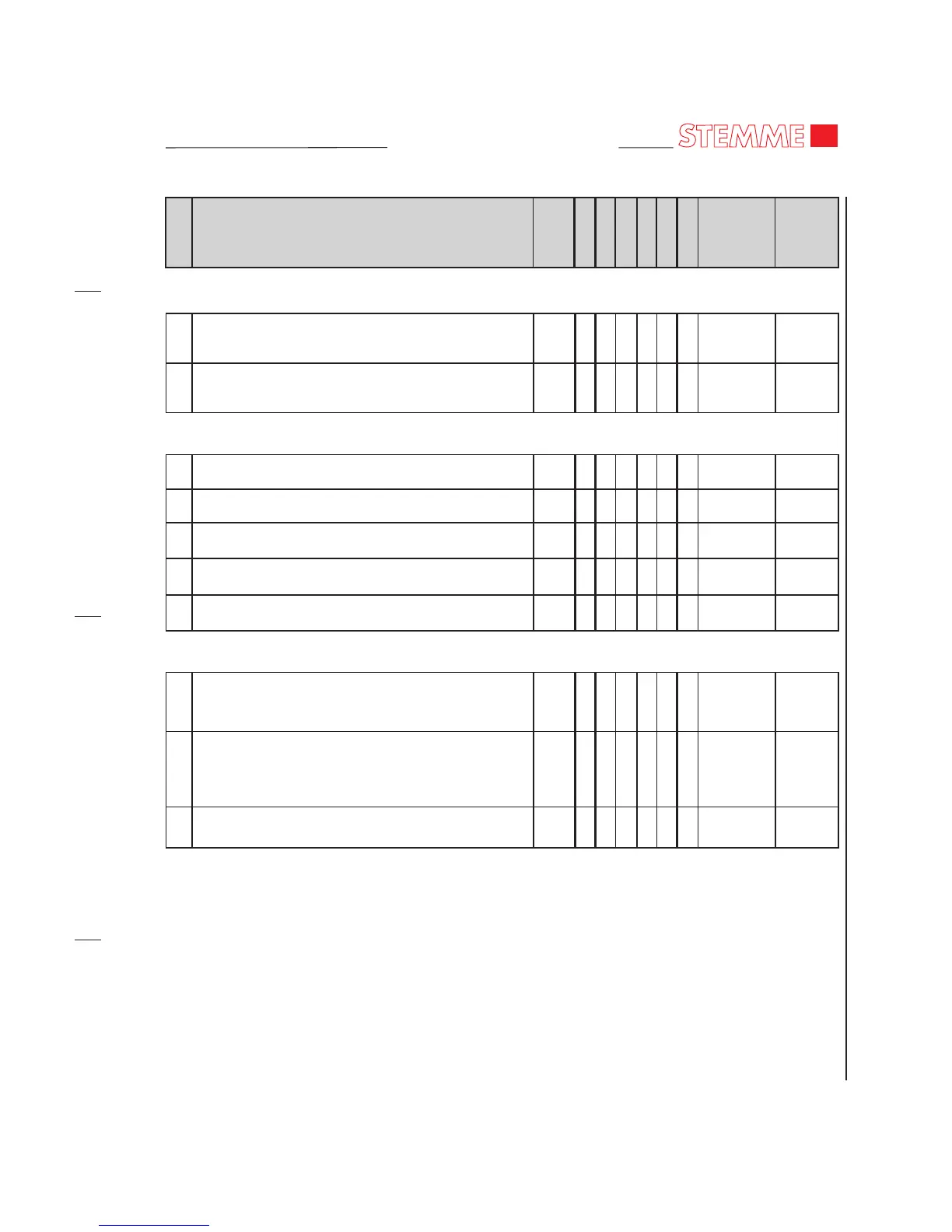

1. Remove main gear fairings and inspect for

damages.

2. Verify the bearings of the wheel shoes are free

moveable.

3. Inspect the main gear legs and trailing arms for

deformation and possible cracks as a result of an

excessive load.

4. Check condition of main gear tires and creep

markings. Check tire pressure: 3.5 ± 0.1 bar / 51.0

± 1.5 p.s.i.

5. Check function of rocking arm spring damping

system.

6. Check wheel bearings for freedom of movement

and excessive play.

7. Check brake master cylinder and wheel brake

cylinders incl. hoses and lines.

8. Check brake discs and brake linings

(at least 1,5 mm / 0.06 in.).

9. Check quantity of brake fluid.

10. Renew brake fluid (DOT 4) if indicated.

1. Remove fairings and inspect for damages.

2. Check condition of nose gear tire and check tire

pressure: 3.5 ± 0.2 bar / 51.0 ± 3.0 p.s.i.

3. Visually inspect wheel fork for cracks or

deformations.

4. Check function of wheel fork damping system.

12-15-00

12-15-00

X

X

X

X

X

X

X

X

X

(X)

X

X

X

X

X

X

X

X

X

X

X

Reference Initials

Motor 100h

Motor 25h

Airframe

100h

Motor 200h

Motor 600h

Motor 1000h

Annual

Type and Subject of Inspection

No.

5.1.17 Main Landing Gear (Fix L/G)

5.1.18 Nose Landing Gear (Fix L/G)

Nov 18/11

Nov 18/11

Loading...

Loading...